Carb Casting Repair, Zinc Solder?

Moderator: Team

-

Kevin Johnson

- HotPass

- Posts: 9406

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Carb Casting Repair, Zinc Solder?

https://www.semasan.com/breaking-news-archives?utm_campaign=DrivingForce_DF272&utm_content=SeeAllLeg

Re: Carb Casting Repair, Zinc Solder?

The color is dead nuts on the money.

Tuner, this makes twice now you've taken shots at my work--if you recall I banned you from my business Facebook page under your alias "Clem Kadiddlehopper" a couple of years ago for the same thing. A mutual acquaintance confirmed your alias.

I've restored thousands of carbs over the last 20+ years I've been doing this, I know what is and isn't correct.

The flash from the camera makes it look brighter and more gold than it actually is. I'm a carb restorer, not a photographer.

Tuner, this makes twice now you've taken shots at my work--if you recall I banned you from my business Facebook page under your alias "Clem Kadiddlehopper" a couple of years ago for the same thing. A mutual acquaintance confirmed your alias.

I've restored thousands of carbs over the last 20+ years I've been doing this, I know what is and isn't correct.

The flash from the camera makes it look brighter and more gold than it actually is. I'm a carb restorer, not a photographer.

Re: Carb Casting Repair, Zinc Solder?

Ooohhh ... banned from your falsebook page !! simply because you can't have an honest discussion with someone who has a different opinion than yours? You think an opinion different than yours is an affront to your opinion, which is only your opinion. My opinion is based on the fact that I was selling new Holley carbs and driving the cars that came with them the years they were brand new, and saw the color change after Colt Industries took over and cut production costs a little bit every year. Perhaps if you post some pictures taken in a different light you can change my opinion. If you are confident in your work why can't you discuss it?

Re: Carb Casting Repair, Zinc Solder?

You weren't looking for an honest discussion then, and you aren't looking for one now. You're trying to stir sh!t.

I don't know why you seem to have an issue with me, and frankly I don't give a rat's a$$ about you nor your opinion of me, but I do remember your perceived issue with me started over on the racing fuel systems page a few years ago--I tried to have an honest discussion about carb restoration over there, and it went downhill after I corrected you about the issue of the "skin" on the zinc castings.

If you don't remember that conversation, I'll refresh your memory: you chided that by media blasting (NOT "sand"), the skin that was left on the parts after they were molded was being destroyed. You were correct--to a point--WHAT WAS LEFT of the original skin on the castings WAS being removed as there was--and is--NO way to save it once the castings had started to corrode. I'd think you would know that the chromate conversion coatings on the castings was NOT put there for aesthetic reasons, it was meant to be a sacrificial coating to protect the castings from corrosion--which it did, and does--to an extent--but it WILL eventually deteriorate when exposed to the elements, and as it does eventually give way, the skin on the castings begins to subsequently deteriorate. Once that happens, there is NO saving that original skin.

That aside, let me ask you a question Tuner/"Clem"--if some stranger were to walk into your "virtual" workplace (in other words, an environment where you earn your living) and start talking sh!t about your work clear out of the blue, I'm betting you wouldn't take too kindly to it. FWIW, our mutual acquaintance agreed you were out of line saying what you said on my page.

Let me ask you another question--how many carburetors have YOU PERSONALLY restored?--I don't mean "rebuilt" or "recalibrated", I mean how many have you actually restored?

Yeah, that's what I thought.

My work has been on some of the highest-end restorations in the WORLD. My work has been on innumerable award winning cars including the NCRS--and if you know what a PITA Corvette aficionados can be, you know that's no easy task. As a matter of fact, over the years I had gathered such a large Corvette clientele that a small percentage of them began to make such nuisances of themselves (and I'm being VERY polite here) that I wound up putting a brutally blunt disclaimer on my website aimed solely at the "nuisance" niche of the Corvette community telling them that I will NOT do work for them. I was told by numerous others in the business that I was shooting myself in the foot by doing so, but a VERY funny thing happened afterwards--I quickly received ENORMOUS support from the Corvette community for having the BALLS to state publicly what everyone else was thinking--and pining for! I've even received support for my stance from some of the highest echelons of the Corvette "governing bodies" THANKING ME for saying what I said, and that they wished they could say the same thing but they were fearful of reprisal should they do so. That was almost a year ago, and the Corvette work is STILL rolling into my shop.

Many of my clients are some of the most well-known and respected car collectors AND restorers in the country. If there were some issue with my work, I would DEFINITELY have heard about it by now--yet the high end restoration work just keeps rolling into my shop. And I've achieved all this working out of a run-down 24' square shop behind my home.

I am intimately familiar with the variances in the coloring and iridescence of the castings over the years, but they were NOT all the same even during the earlier years. I've collected an enormous photographic library over the last near quarter century of low mile and NOS carbs, and even during the early & mid `60's the color & iridescence on the castings could vary dramatically. The carb in the previous pics was a `70 BOSS 302 unit, and they were typically a darker color and less iridescent than earlier units, but NOT always.

I often refer to the remnants of the original finishes of a carb when it comes apart that can sometimes be seen in areas such as the inside of the secondary housing cover and the power valve cavities--these areas are somewhat shielded from the environment, and as such it's not uncommon for the original finishes to remain. That said, just because the inside of the secondary cover might be a light green/gold with a strong iridescence does NOT mean the rest of the castings wore an identical finish. I've had NUMEROUS NOS carbs on my bench where the color and finish varied WILDLY from one casting to another--again, these finishes weren't put there for aesthetic reasons, and Holley (et al.) didn't give a rat's a$$ if the color on the primary and secondary float bowls matched.

Tuner/"Clem", you've been around a long time, and you're obviously a sharp guy, and I'm sure you have a LOT of knowledge to share with others--and honestly I would've loved to sit down with you over a couple of cold ones and chew the fat, but somewhere along the line you seem to have closed off your ears and opened your mouth further and have no interest in hearing (/learning) what someone else might have to offer. NO ONE knows everything about everything. I'm damn near 60 and still learn things about carburetors (and pretty much everything else in life) on a frequent basis.

It's a shame you couldn't extend the same courtesy.

I don't know why you seem to have an issue with me, and frankly I don't give a rat's a$$ about you nor your opinion of me, but I do remember your perceived issue with me started over on the racing fuel systems page a few years ago--I tried to have an honest discussion about carb restoration over there, and it went downhill after I corrected you about the issue of the "skin" on the zinc castings.

If you don't remember that conversation, I'll refresh your memory: you chided that by media blasting (NOT "sand"), the skin that was left on the parts after they were molded was being destroyed. You were correct--to a point--WHAT WAS LEFT of the original skin on the castings WAS being removed as there was--and is--NO way to save it once the castings had started to corrode. I'd think you would know that the chromate conversion coatings on the castings was NOT put there for aesthetic reasons, it was meant to be a sacrificial coating to protect the castings from corrosion--which it did, and does--to an extent--but it WILL eventually deteriorate when exposed to the elements, and as it does eventually give way, the skin on the castings begins to subsequently deteriorate. Once that happens, there is NO saving that original skin.

That aside, let me ask you a question Tuner/"Clem"--if some stranger were to walk into your "virtual" workplace (in other words, an environment where you earn your living) and start talking sh!t about your work clear out of the blue, I'm betting you wouldn't take too kindly to it. FWIW, our mutual acquaintance agreed you were out of line saying what you said on my page.

Let me ask you another question--how many carburetors have YOU PERSONALLY restored?--I don't mean "rebuilt" or "recalibrated", I mean how many have you actually restored?

Yeah, that's what I thought.

My work has been on some of the highest-end restorations in the WORLD. My work has been on innumerable award winning cars including the NCRS--and if you know what a PITA Corvette aficionados can be, you know that's no easy task. As a matter of fact, over the years I had gathered such a large Corvette clientele that a small percentage of them began to make such nuisances of themselves (and I'm being VERY polite here) that I wound up putting a brutally blunt disclaimer on my website aimed solely at the "nuisance" niche of the Corvette community telling them that I will NOT do work for them. I was told by numerous others in the business that I was shooting myself in the foot by doing so, but a VERY funny thing happened afterwards--I quickly received ENORMOUS support from the Corvette community for having the BALLS to state publicly what everyone else was thinking--and pining for! I've even received support for my stance from some of the highest echelons of the Corvette "governing bodies" THANKING ME for saying what I said, and that they wished they could say the same thing but they were fearful of reprisal should they do so. That was almost a year ago, and the Corvette work is STILL rolling into my shop.

Many of my clients are some of the most well-known and respected car collectors AND restorers in the country. If there were some issue with my work, I would DEFINITELY have heard about it by now--yet the high end restoration work just keeps rolling into my shop. And I've achieved all this working out of a run-down 24' square shop behind my home.

I am intimately familiar with the variances in the coloring and iridescence of the castings over the years, but they were NOT all the same even during the earlier years. I've collected an enormous photographic library over the last near quarter century of low mile and NOS carbs, and even during the early & mid `60's the color & iridescence on the castings could vary dramatically. The carb in the previous pics was a `70 BOSS 302 unit, and they were typically a darker color and less iridescent than earlier units, but NOT always.

I often refer to the remnants of the original finishes of a carb when it comes apart that can sometimes be seen in areas such as the inside of the secondary housing cover and the power valve cavities--these areas are somewhat shielded from the environment, and as such it's not uncommon for the original finishes to remain. That said, just because the inside of the secondary cover might be a light green/gold with a strong iridescence does NOT mean the rest of the castings wore an identical finish. I've had NUMEROUS NOS carbs on my bench where the color and finish varied WILDLY from one casting to another--again, these finishes weren't put there for aesthetic reasons, and Holley (et al.) didn't give a rat's a$$ if the color on the primary and secondary float bowls matched.

Tuner/"Clem", you've been around a long time, and you're obviously a sharp guy, and I'm sure you have a LOT of knowledge to share with others--and honestly I would've loved to sit down with you over a couple of cold ones and chew the fat, but somewhere along the line you seem to have closed off your ears and opened your mouth further and have no interest in hearing (/learning) what someone else might have to offer. NO ONE knows everything about everything. I'm damn near 60 and still learn things about carburetors (and pretty much everything else in life) on a frequent basis.

It's a shame you couldn't extend the same courtesy.

-

Kevin Johnson

- HotPass

- Posts: 9406

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Carb Casting Repair, Zinc Solder?

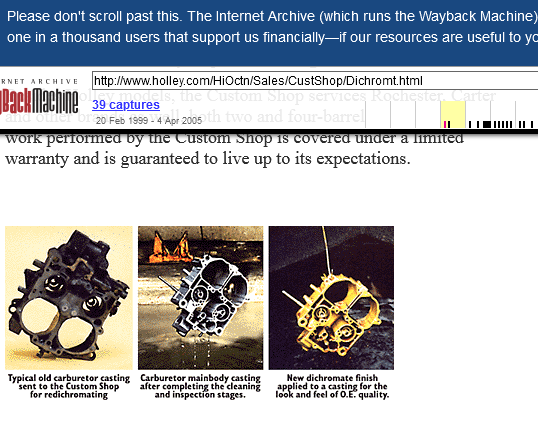

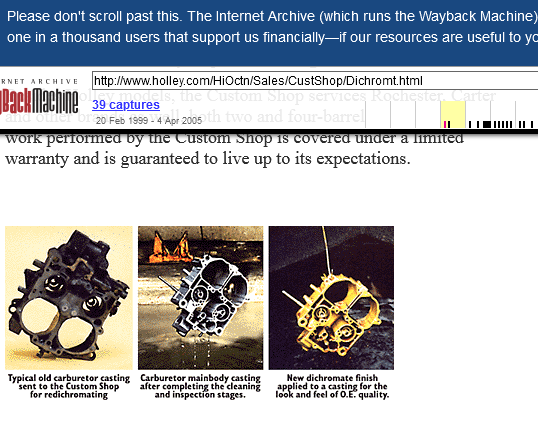

Holley's webpage from 1997:

https://web.archive.org/web/19971212052 ... olley.com/

The 1997 site provides hyperlinks: "From Holley's world-famous Custom Shop, you'll be able order a variety of services online, including powder coating, plating, dichromating, and rebuilding services." ... "After going through a series of extensive cleanings, each casting sports a smooth, even dichromate coating that is indistinguishable from a new carb in every respect, including color."

The archived page below (captured circa 2005) has in-process pictures of their in-house restoration service.

https://web.archive.org/web/19990220142 ... hromt.html

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

https://web.archive.org/web/19971212052 ... olley.com/

The 1997 site provides hyperlinks: "From Holley's world-famous Custom Shop, you'll be able order a variety of services online, including powder coating, plating, dichromating, and rebuilding services." ... "After going through a series of extensive cleanings, each casting sports a smooth, even dichromate coating that is indistinguishable from a new carb in every respect, including color."

The archived page below (captured circa 2005) has in-process pictures of their in-house restoration service.

https://web.archive.org/web/19990220142 ... hromt.html

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

https://www.semasan.com/breaking-news-archives?utm_campaign=DrivingForce_DF272&utm_content=SeeAllLeg

Re: Carb Casting Repair, Zinc Solder?

You can stir all your want and throw blame on whoever you want, i just stated an opinion.

I hope you don't think you are being insulted to be reminded you were (are) a guest in our carb forum. I don't recall any of your perceived insults, nor do I give two $hits if you banned me. I didn't ban you. In fact, I have never banned anybody, ever, except for chinese spammers posting ugg boots BS and the like.I don't know why you seem to have an issue with me, and frankly I don't give a rat's a$$ about you nor your opinion of me, but I do remember your perceived issue with me started over on the racing fuel systems page a few years ago--I tried to have an honest discussion about carb restoration over there, and it went downhill after I corrected you about the issue of the "skin" on the zinc castings.

If you don't remember that conversation, I'll refresh your memory: you chided that by media blasting (NOT "sand"), the skin that was left on the parts after they were molded was being destroyed. You were correct--to a point--WHAT WAS LEFT of the original skin on the castings WAS being removed as there was--and is--NO way to save it once the castings had started to corrode. I'd think you would know that the chromate conversion coatings on the castings was NOT put there for aesthetic reasons, it was meant to be a sacrificial coating to protect the castings from corrosion--which it did, and does--to an extent--but it WILL eventually deteriorate when exposed to the elements, and as it does eventually give way, the skin on the castings begins to subsequently deteriorate. Once that happens, there is NO saving that original skin.

That aside, let me ask you a question Tuner/"Clem"--if some stranger were to walk into your "virtual" workplace (in other words, an environment where you earn your living) and start talking sh!t about your work clear out of the blue, I'm betting you wouldn't take too kindly to it. FWIW, our mutual acquaintance agreed you were out of line saying what you said on my page.

Let me ask you another question--how many carburetors have YOU PERSONALLY restored?--I don't mean "rebuilt" or "recalibrated", I mean how many have you actually restored?

Yeah, that's what I thought.

My work has been on some of the highest-end restorations in the WORLD. My work has been on innumerable award winning cars including the NCRS--and if you know what a PITA Corvette aficionados can be, you know that's no easy task. As a matter of fact, over the years I had gathered such a large Corvette clientele that a small percentage of them began to make such nuisances of themselves (and I'm being VERY polite here) that I wound up putting a brutally blunt disclaimer on my website aimed solely at the "nuisance" niche of the Corvette community telling them that I will NOT do work for them. I was told by numerous others in the business that I was shooting myself in the foot by doing so, but a VERY funny thing happened afterwards--I quickly received ENORMOUS support from the Corvette community for having the BALLS to state publicly what everyone else was thinking--and pining for! I've even received support for my stance from some of the highest echelons of the Corvette "governing bodies" THANKING ME for saying what I said, and that they wished they could say the same thing but they were fearful of reprisal should they do so. That was almost a year ago, and the Corvette work is STILL rolling into my shop.

Many of my clients are some of the most well-known and respected car collectors AND restorers in the country. If there were some issue with my work, I would DEFINITELY have heard about it by now--yet the high end restoration work just keeps rolling into my shop. And I've achieved all this working out of a run-down 24' square shop behind my home.

I am intimately familiar with the variances in the coloring and iridescence of the castings over the years, but they were NOT all the same even during the earlier years. I've collected an enormous photographic library over the last near quarter century of low mile and NOS carbs, and even during the early & mid `60's the color & iridescence on the castings could vary dramatically. The carb in the previous pics was a `70 BOSS 302 unit, and they were typically a darker color and less iridescent than earlier units, but NOT always.

A difference of opinion is not a legitimate reason to ban.

Now all of a sudden you claim my opinion is your opinion all along. Why didn't you acknowledge this in the first place and move along, instead of whine like somebody is kicking your dog.

If you think your word salad is a "same courtesy" you must be drinking that KaliphoniaKoolAid that caused you to think yours is the only opinion that matters.I often refer to the remnants of the original finishes of a carb when it comes apart that can sometimes be seen in areas such as the inside of the secondary housing cover and the power valve cavities--these areas are somewhat shielded from the environment, and as such it's not uncommon for the original finishes to remain. That said, just because the inside of the secondary cover might be a light green/gold with a strong iridescence does NOT mean the rest of the castings wore an identical finish. I've had NUMEROUS NOS carbs on my bench where the color and finish varied WILDLY from one casting to another--again, these finishes weren't put there for aesthetic reasons, and Holley (et al.) didn't give a rat's a$$ if the color on the primary and secondary float bowls matched.

Tuner/"Clem", you've been around a long time, and you're obviously a sharp guy, and I'm sure you have a LOT of knowledge to share with others--and honestly I would've loved to sit down with you over a couple of cold ones and chew the fat, but somewhere along the line you seem to have closed off your ears and opened your mouth further and have no interest in hearing (/learning) what someone else might have to offer. NO ONE knows everything about everything. I'm damn near 60 and still learn things about carburetors (and pretty much everything else in life) on a frequent basis.

It's a shame you couldn't extend the same courtesy.

I didn't say you did shoddy work or your work was no good, I merely said your example is the wrong color, and I also suggested how you can change the color, but that was a waste of time because you already know everything there is to know that matters. Good for you.

Now, you are repeating my opinion back as if you were there all along. Other than your variation of wording, isn't this exactly what I said in the first place?

Have a nice day.You wrote:I am intimately familiar with the variances in the coloring and iridescence of the castings over the years, but they were NOT all the same even during the earlier years.

Re: Carb Casting Repair, Zinc Solder?

No dog in this fight, and not aimed at anyone, but ......

From someone who has processed tens of thousands of chromate/dichromate zinc die castings in a former life ...... it's usually just a pre-treatment for powder coating ..... I haven't got clue how any one could closely control the actual 'colour' of each individual part to any real degree of repeatability

Not only did they vary batch to batch, they also varied part to part within each batch ...... I'm talking commercial processing here, as Holley would have done, not artisan small batch work which I guess you might have more control over

The reasons for the observed 'discolouration' was the subject of various sensible theories, but as it wasn't my problem was never investigated further

And I very much doubt Holley would have been overly concerned about it either ......

From someone who has processed tens of thousands of chromate/dichromate zinc die castings in a former life ...... it's usually just a pre-treatment for powder coating ..... I haven't got clue how any one could closely control the actual 'colour' of each individual part to any real degree of repeatability

Not only did they vary batch to batch, they also varied part to part within each batch ...... I'm talking commercial processing here, as Holley would have done, not artisan small batch work which I guess you might have more control over

The reasons for the observed 'discolouration' was the subject of various sensible theories, but as it wasn't my problem was never investigated further

And I very much doubt Holley would have been overly concerned about it either ......

Re: Carb Casting Repair, Zinc Solder?

Agreed BC, production passivate tanks were run till they pretty much didn't look right or became fouled. Then they would be topped up or drained and re filled if fouled.

The coatings no matter how good age, i have seen new old stock that has been wrapped up all its life, with blemishes, dulling and color variance all on the one part.

The coatings no matter how good age, i have seen new old stock that has been wrapped up all its life, with blemishes, dulling and color variance all on the one part.

Re: Carb Casting Repair, Zinc Solder?

In the field of carb restoration, processing the castings is BY FAR the biggest PITA of the entire job.

Obviously I'm not going to publicly discuss the proprietary methods, processes and products involved in achieving aesthetically pleasing and (reasonably) consistent results, but the previous 2 posts are absolutely spot-on.

If this forum permitted hosting pics, I could post a nearly endless array of pics showing the varying finishes of all makes & models of carbs, but as it doesn't I'm not going to bother finding a suitable location to host them just to link them back here.

FWIW, I have 2 pictures of the vacuum secondary housing covers off of a `67 dated Corvette 3659/3660 3X2 set. As you might expect, the external finishes were completely gone by the time they landed on my workbench, so externally they all looked pretty much the same--corroded, flat, dull gray. However, once I disassembled them, I found the inside surface of the 2 secondary covers both to be in superb condition--and of strikingly different appearance.

One was absurdly bright (almost appeared to have been plated), shiny, and heavily iridescent with a strong rainbow presence of green, blue, purple, and red, with a heavy emphasis on the red. The other was maybe 50% as bright, with moderate iridescence and far less red/blue/purple, with a heavier emphasis on green.

Again, these came from the same set of 100% verified unmolested carbs (the car was a low mileage barn find that had been parked in the early `70's if memory serves).

Apparently no one notified the Holley employee who originally built these carbs that the finishes on the castings had to be better matched.

I don't know if I still have the pics or not, but at one point I had pics of 2 separate but closely dated 1970 Holley LIST 4555 carbs (`70 LT1 350 49 state manual transmission) that were both genuine low mileage survivors which retained an exceptional amount of their original finishes. Much like the Corvette situation above, one was surprisingly iridescent, but the color was somewhat more green/gold and the red/purple hues were a little lighter. The other was a hideous flat dark brown that looked much like what used to come out of the Holley restoration shop years ago.

Over the last decade or so, what people have come to expect in regards to the term "restored" has changed dramatically. If I were to hand a "restored" carburetor back to a customer today that legitimately looked like it did when it was original, they'd likely run my a$$ up a flagpole screaming at the top of their lungs that it looked like $hit. (where have we heard that before?) There's no universally accepted "correct" finish desired by customers--no matter what, some will say it's too shiny, others will say it's too dull. Some will say it's too gold, others will say it's too green. That's why I typically try to look for whatever remnants of the original finishes that might remain and use that as a general guideline when processing a carb.

Again, processing the castings is by far the most difficult--and time-consuming part of the job. It typically takes me 30-45 minutes to completely disassemble a divorced choke 4150 Holley when it hasn't either been butchered by a previous hack "restoration" or isn't corroded to hell and back. That includes pulling the vacuum tubes from the castings so they can be plated and removing all the metering block well plugs and/or emulsion/idle tubes.

My cleaning process is proprietary, but from start to finish--and by "finish" I mean where the parts are ready to be media processed takes about 2-3 hours, sometimes much longer if significant hand cleaning is required to remove heavy carbon deposits, etc. From the time the castings go into media processing to being refinished and ready to set aside to allow the new finish to cure is another 2-3 hours on average--but there have been many times where the castings required multiple trips through both cleaning AND media processes before they were ready to be refinished. Once someone's been at this for a while, one's eye learns the subtle differences in the appearance of the bare castings after media processing, and can usually spot the parts that are likely to be uncooperative trouble-makers--and that happens WAY more often than one might think.

Reassembly typically takes me another 90 minutes or so, again depending on the specific unit involved and it's previous history. Many times after pin gauging a carb I find that someone's already been into it to "tune" it ( ) and I have to go through that to un-scramble that egg. Not fun. Afterwards the carbs get live tested on a running test engine that's equipped with a wideband O2 to make sure it's not going to do anything stupid and to verify the adjustment parameters are within range. BEST-case scenario for me for a divorced choke 4150 Holley is about 8 hours from initial disassembly to plopping the carb on the live test engine, not including cure time for the castings after refinishing, that's mostly actual hands-on time.

) and I have to go through that to un-scramble that egg. Not fun. Afterwards the carbs get live tested on a running test engine that's equipped with a wideband O2 to make sure it's not going to do anything stupid and to verify the adjustment parameters are within range. BEST-case scenario for me for a divorced choke 4150 Holley is about 8 hours from initial disassembly to plopping the carb on the live test engine, not including cure time for the castings after refinishing, that's mostly actual hands-on time.

I guess it shouldn't be such a surprise after all these years to still have to contend with "internet experts" who've never actually either seen the restoration process with their own 2 eyes, or let alone done it themselves.

A few years back, someone actually made the following comment on a FaRcebook car group--and I quote verbatim:

"Carb restoration is easy, all you need is a sandblaster and a bucket of chromate!"

I'll leave it at that...for now.

Obviously I'm not going to publicly discuss the proprietary methods, processes and products involved in achieving aesthetically pleasing and (reasonably) consistent results, but the previous 2 posts are absolutely spot-on.

If this forum permitted hosting pics, I could post a nearly endless array of pics showing the varying finishes of all makes & models of carbs, but as it doesn't I'm not going to bother finding a suitable location to host them just to link them back here.

FWIW, I have 2 pictures of the vacuum secondary housing covers off of a `67 dated Corvette 3659/3660 3X2 set. As you might expect, the external finishes were completely gone by the time they landed on my workbench, so externally they all looked pretty much the same--corroded, flat, dull gray. However, once I disassembled them, I found the inside surface of the 2 secondary covers both to be in superb condition--and of strikingly different appearance.

One was absurdly bright (almost appeared to have been plated), shiny, and heavily iridescent with a strong rainbow presence of green, blue, purple, and red, with a heavy emphasis on the red. The other was maybe 50% as bright, with moderate iridescence and far less red/blue/purple, with a heavier emphasis on green.

Again, these came from the same set of 100% verified unmolested carbs (the car was a low mileage barn find that had been parked in the early `70's if memory serves).

Apparently no one notified the Holley employee who originally built these carbs that the finishes on the castings had to be better matched.

I don't know if I still have the pics or not, but at one point I had pics of 2 separate but closely dated 1970 Holley LIST 4555 carbs (`70 LT1 350 49 state manual transmission) that were both genuine low mileage survivors which retained an exceptional amount of their original finishes. Much like the Corvette situation above, one was surprisingly iridescent, but the color was somewhat more green/gold and the red/purple hues were a little lighter. The other was a hideous flat dark brown that looked much like what used to come out of the Holley restoration shop years ago.

Over the last decade or so, what people have come to expect in regards to the term "restored" has changed dramatically. If I were to hand a "restored" carburetor back to a customer today that legitimately looked like it did when it was original, they'd likely run my a$$ up a flagpole screaming at the top of their lungs that it looked like $hit. (where have we heard that before?) There's no universally accepted "correct" finish desired by customers--no matter what, some will say it's too shiny, others will say it's too dull. Some will say it's too gold, others will say it's too green. That's why I typically try to look for whatever remnants of the original finishes that might remain and use that as a general guideline when processing a carb.

Again, processing the castings is by far the most difficult--and time-consuming part of the job. It typically takes me 30-45 minutes to completely disassemble a divorced choke 4150 Holley when it hasn't either been butchered by a previous hack "restoration" or isn't corroded to hell and back. That includes pulling the vacuum tubes from the castings so they can be plated and removing all the metering block well plugs and/or emulsion/idle tubes.

My cleaning process is proprietary, but from start to finish--and by "finish" I mean where the parts are ready to be media processed takes about 2-3 hours, sometimes much longer if significant hand cleaning is required to remove heavy carbon deposits, etc. From the time the castings go into media processing to being refinished and ready to set aside to allow the new finish to cure is another 2-3 hours on average--but there have been many times where the castings required multiple trips through both cleaning AND media processes before they were ready to be refinished. Once someone's been at this for a while, one's eye learns the subtle differences in the appearance of the bare castings after media processing, and can usually spot the parts that are likely to be uncooperative trouble-makers--and that happens WAY more often than one might think.

Reassembly typically takes me another 90 minutes or so, again depending on the specific unit involved and it's previous history. Many times after pin gauging a carb I find that someone's already been into it to "tune" it (

I guess it shouldn't be such a surprise after all these years to still have to contend with "internet experts" who've never actually either seen the restoration process with their own 2 eyes, or let alone done it themselves.

A few years back, someone actually made the following comment on a FaRcebook car group--and I quote verbatim:

"Carb restoration is easy, all you need is a sandblaster and a bucket of chromate!"

I'll leave it at that...for now.

Re: Carb Casting Repair, Zinc Solder?

VMC wrote:If this forum permitted hosting pics, I could post a nearly endless array of pics showing the varying finishes of all makes & models of carbs, but as it doesn't I'm not going to bother finding a suitable location to host them just to link them back here.

It does, has done for many years, unless I'm reading you incorrectly ....... and if a dummy like me can navigate it, there's hope for the majority if humanity

Write out your post, click on 'Preview'

Below you will see 'Options' and 'Attachments', click on the latter

Upload a file from your computer ...... obviously including picture files ...... and then use the 'Place inline' option to fit it into the post where required

Hope this is of use

Re: Carb Casting Repair, Zinc Solder?

My mistake, I didn't realize pics could be hosted here, I noticed many people like Larry Meaux often hot-linked Photobucket pics here, so I was under the impression they had to be hosted elsewhere.

Bright iridescent 3X2 cover

Normal 3X2 cover

I didn't mention these above, but here's a pair of NOS 1965 big block HP "peanut" float bowls I restored for a client's real-deal `65 Z16 Chevelle.

Here's the NOS bowls; notice the color, but also how much they had faded over the years.

Here's after I restored them to match what the rest of the original March 1965 LIST 3310 looked like inside when it came apart. Again, the pics don't tell the story 100%, but as I said earlier, I'm a carb restorer, not a photographer.

I'll try to find the LIST 4555 pics later, I have a couple of Cowboy cut Ribeye steaks in the smoker that need tended to at the moment.

Bright iridescent 3X2 cover

Normal 3X2 cover

I didn't mention these above, but here's a pair of NOS 1965 big block HP "peanut" float bowls I restored for a client's real-deal `65 Z16 Chevelle.

Here's the NOS bowls; notice the color, but also how much they had faded over the years.

Here's after I restored them to match what the rest of the original March 1965 LIST 3310 looked like inside when it came apart. Again, the pics don't tell the story 100%, but as I said earlier, I'm a carb restorer, not a photographer.

I'll try to find the LIST 4555 pics later, I have a couple of Cowboy cut Ribeye steaks in the smoker that need tended to at the moment.

You do not have the required permissions to view the files attached to this post.

Re: Carb Casting Repair, Zinc Solder?

A few more pics for comparison's sake.

Correction re: the pair of low mileage 4555 survivors--one is/was a 4555 survivor, the other is a NOS 4490 dated 023, or the 3rd week of February 1970. Note that very shortly after February 1970. the GM 780 carbs started showing up with a secondary squirter boss cast into the secondary venturi of the carb bodies. The early February and prior bodies did not have these bosses.

Here's the 023 dated 4490, note the lack of a secondary squirter boss.

Here's a decent look at the finish--that ugly flat dark brown as mentioned earlier.

Here's the 4555 survivor. I don't have the exact date for this one, but as it does have the secondary squirter boss, it's a March 1970 or later dated unit.

Here's a NOS 3246 dated 7B1 (1966 L72 B body dated the 1st week of December 1967 making it an early service dated unit). Note the color--the same hideous flat, dark brown.

Here's a NOS 4296 dated 951 (1969 L88/ZL-1 dated the 1st week of May 1969)

Notice how the bowls and main body are visibly "duller" than the metering blocks, which are somewhat "shiny", but the color is basically the same.

But WAIT!--look at the accelerator pump cover!--flat, dull green!

Moving away from Holleys for a moment, here's a NOS 7041268 Quadrajet ('71 Pontiac). Notice not only the weak, almost completely non-iridescent finish, but the inconsistency between the main body, the top casting, and the vent stack.

Back to Holleys for a moment--here's a brand new Holley double pumper straight out of the box. The pic speaks for itself.

Can you imagine the backlash I'd get if I sent a customer's "restored" carb back to them looking like this?!?

Maybe I should just start making them all look like THIS example ("restored" by another vendor)

Hopefully this helps clarify the points I was trying to make earlier. If not, feel free to let me know, I literally have thousands more pics I could post.

Correction re: the pair of low mileage 4555 survivors--one is/was a 4555 survivor, the other is a NOS 4490 dated 023, or the 3rd week of February 1970. Note that very shortly after February 1970. the GM 780 carbs started showing up with a secondary squirter boss cast into the secondary venturi of the carb bodies. The early February and prior bodies did not have these bosses.

Here's the 023 dated 4490, note the lack of a secondary squirter boss.

Here's a decent look at the finish--that ugly flat dark brown as mentioned earlier.

Here's the 4555 survivor. I don't have the exact date for this one, but as it does have the secondary squirter boss, it's a March 1970 or later dated unit.

Here's a NOS 3246 dated 7B1 (1966 L72 B body dated the 1st week of December 1967 making it an early service dated unit). Note the color--the same hideous flat, dark brown.

Here's a NOS 4296 dated 951 (1969 L88/ZL-1 dated the 1st week of May 1969)

Notice how the bowls and main body are visibly "duller" than the metering blocks, which are somewhat "shiny", but the color is basically the same.

But WAIT!--look at the accelerator pump cover!--flat, dull green!

Moving away from Holleys for a moment, here's a NOS 7041268 Quadrajet ('71 Pontiac). Notice not only the weak, almost completely non-iridescent finish, but the inconsistency between the main body, the top casting, and the vent stack.

Back to Holleys for a moment--here's a brand new Holley double pumper straight out of the box. The pic speaks for itself.

Can you imagine the backlash I'd get if I sent a customer's "restored" carb back to them looking like this?!?

Maybe I should just start making them all look like THIS example ("restored" by another vendor)

Hopefully this helps clarify the points I was trying to make earlier. If not, feel free to let me know, I literally have thousands more pics I could post.

You do not have the required permissions to view the files attached to this post.

Re: Carb Casting Repair, Zinc Solder?

Same here, i definitely do not want to pick a side in this topic, but.

The term restoration to many can mean two things. Restoration to end of production line replication, coatings, paint finishes, standard plating, everything standard as the product came off the line.

Then there is restoration to perfection or near enough, attention to all detail on every part, no random flashes on castings, panel fit, no undercarriage coating marring, upholstery that follows production patterns but use materials and detail not seen on the production line.

Take your pick of which one you prefer, but there will be a definite clash between vendor and customer if those choices dont match, both can be right in their own way, but differ.

Some years back i did a restoration on a motorcycle, i replicated everything that was detailed in the parts book for that machine, fastener crown stampings, exact washer dimensions, every plating finish replicated. On the bike being seen by a person know for judging at shows, he noted that some of the plating was irregular, but surprisingly suggested that a set of stainless spokes would be acceptable for this vehicle in some circles. To me the problem was that this thing was manufactured with zinc plated spokes that with age take on their own patina, apparently to one oracle this was negotiable.

I have seen more than enough plating lines, not one had a colour match card in the inspection area, just an operator who judges when the tanks were due for service. Obviously in an end of production line restoration it is nice for everything to look as tidy as it can be presented, in a show, replication of process could be a deciding point, but really, the judge should accept any variance that that vehicle was manufactured with without bias.

The term restoration to many can mean two things. Restoration to end of production line replication, coatings, paint finishes, standard plating, everything standard as the product came off the line.

Then there is restoration to perfection or near enough, attention to all detail on every part, no random flashes on castings, panel fit, no undercarriage coating marring, upholstery that follows production patterns but use materials and detail not seen on the production line.

Take your pick of which one you prefer, but there will be a definite clash between vendor and customer if those choices dont match, both can be right in their own way, but differ.

Some years back i did a restoration on a motorcycle, i replicated everything that was detailed in the parts book for that machine, fastener crown stampings, exact washer dimensions, every plating finish replicated. On the bike being seen by a person know for judging at shows, he noted that some of the plating was irregular, but surprisingly suggested that a set of stainless spokes would be acceptable for this vehicle in some circles. To me the problem was that this thing was manufactured with zinc plated spokes that with age take on their own patina, apparently to one oracle this was negotiable.

I have seen more than enough plating lines, not one had a colour match card in the inspection area, just an operator who judges when the tanks were due for service. Obviously in an end of production line restoration it is nice for everything to look as tidy as it can be presented, in a show, replication of process could be a deciding point, but really, the judge should accept any variance that that vehicle was manufactured with without bias.

Re: Carb Casting Repair, Zinc Solder?

It's a huge pissing match, well, who started first? yuck

Heat is energy, energy is horsepower...but you gotta control the heat.

-Carl

-Carl

Re: Carb Casting Repair, Zinc Solder?

A couple of pertinent anecdotes re: the general field of restoration, if I may without wandering too far off the topic of this thread;

One of my best clients (and now good friend) got his start in the restoration field in the `80's working for a high-end Corvette restoration shop. They had just completed a 100% nut and bolt restoration on a 1953 Corvette. The car owner arrived to go over the car, and after thoroughly examining it, he and the owner of the business went to the office and closed the door.

A little while later they emerged--the car owner left, and the business owner took my friend aside and told him "If you ever do that to me again, you're out on your ass." Obviously puzzled, my friend asked what specifically the 4-alarm issue was that had the car owner so bent out of shape.

It turns out that the washer for the battery's negative ground cable attachment had inadvertently been installed upside-down.

That was it.

That was the 4-alarm crisis.

He left that business not long after and started his own restoration business, eventually to became one of the Nation's foremost experts on 1970-1972 Chevelle restoration, specializing in LS6 and L78 cars. I've done countless carburetor restorations for him over the years, including a legitimate one-of-one 1970 L89 (396/375 HP with aluminum heads) Chevelle convertible that he's just putting the finishing touches on now.

My most privileged job with him however was when he chose me to do a complete rebuild & dyno on the born-with numbers matching L72 427 for his personal real-deal ultra-low mileage (but beat hard and put away wet) garage-find 1969 YENKO Chevelle. I've done more engines than I can remember over the years, but that one is hands-down my most treasured and honored job. I will admit though that it was literally terrifying watching that born-with/deep 4-figure valued block singing along at 6000 RPM on Ohio George Montgomery's dyno lol. Thankfully all went well, and I have one very special memory I'll never forget.

Sorry if this wandered too far off-topic.

One of my best clients (and now good friend) got his start in the restoration field in the `80's working for a high-end Corvette restoration shop. They had just completed a 100% nut and bolt restoration on a 1953 Corvette. The car owner arrived to go over the car, and after thoroughly examining it, he and the owner of the business went to the office and closed the door.

A little while later they emerged--the car owner left, and the business owner took my friend aside and told him "If you ever do that to me again, you're out on your ass." Obviously puzzled, my friend asked what specifically the 4-alarm issue was that had the car owner so bent out of shape.

It turns out that the washer for the battery's negative ground cable attachment had inadvertently been installed upside-down.

That was it.

That was the 4-alarm crisis.

He left that business not long after and started his own restoration business, eventually to became one of the Nation's foremost experts on 1970-1972 Chevelle restoration, specializing in LS6 and L78 cars. I've done countless carburetor restorations for him over the years, including a legitimate one-of-one 1970 L89 (396/375 HP with aluminum heads) Chevelle convertible that he's just putting the finishing touches on now.

My most privileged job with him however was when he chose me to do a complete rebuild & dyno on the born-with numbers matching L72 427 for his personal real-deal ultra-low mileage (but beat hard and put away wet) garage-find 1969 YENKO Chevelle. I've done more engines than I can remember over the years, but that one is hands-down my most treasured and honored job. I will admit though that it was literally terrifying watching that born-with/deep 4-figure valued block singing along at 6000 RPM on Ohio George Montgomery's dyno lol. Thankfully all went well, and I have one very special memory I'll never forget.

Sorry if this wandered too far off-topic.