Someone probably noticed that a fluidic metal moving back and forth inside the hollow stem will also help dampen oscillation. That is not present with an empty tube.RW TECH wrote: What it had going for itself is someone must have been paying attention to make sure the valvetrain wasn't going to throw up all over itself at above 8K RPM with all those "stockish" parts.

Valve stem seals crushed, LS7. More spring?

Moderator: Team

-

Kevin Johnson

- HotPass

- Posts: 9389

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Valve stem seals crushed, LS7. More spring?

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

Re: Valve stem seals crushed, LS7. More spring?

Could be.Kevin Johnson wrote: Someone probably noticed that a fluidic metal moving back and forth inside the hollow stem will also help dampen oscillation. That is not present with an empty tube.

Re: Valve stem seals crushed, LS7. More spring?

And since it's not anchored in place, the weight of the sodium is perhaps effectively subtracted from the valve's measured weight or at least might shave some of the peaks off the inertia load spikes. Sounds like a job for Spintron!.. (with a valve heated above 100° C. of course)

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

-

Kevin Johnson

- HotPass

- Posts: 9389

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Valve stem seals crushed, LS7. More spring?

It's a blessing and a curse. I think the possible supercooling effect is one of the (if not THE) root cause(s) of the dropped exh valves. Exhaust residue then adheres and becomes an abrasive. The complexity of the analysis with different climates, fuels and operator behavior made the problem too complex to model reliably (at least at the time). It addresses the non-intuitive issue of owners that babied their cars also having failures. GM would (should) have been aware of the issue through contemporary patent searches.

http://www.google.com/patents/US5769037

http://www.google.com/patents/US5769037

Metal Na is solid at room temperature and melted at operating temperature of the valve element. But the melting point thereof is relatively low, such as about 98° C. Accordingly, metal Na has been already melted during warm-up operation of the engine or low speed operation right after running, and the valve head may be subjected to supercooling by heat exchange of metal Na. So self-cleaning action fails, so that combustion product which is contained in an exhaust gas or lubricating oil which drops owing to oil-down is adhered and deposited on the valve head.

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

Re: Valve stem seals crushed, LS7. More spring?

They might have done it that way too, by pre-heating the oil & spinning the rig at something reasonable like 2K RPM. I would bet that valve got even hotter if they ran the test at 200 cycles per RPM point, ramping up 100 RPM at a time starting from 4K RPM, then continuing on to over 8K RPM until some limiting speed was determined by, say, exceeding a bounce on closing target & maybe if the thing wouldn't clean up during the next 100 RPM increment.MadBill wrote:And since it's not anchored in place, the weight of the sodium is perhaps effectively subtracted from the valve's measured weight or at least might shave some of the peaks off the inertia load spikes. Sounds like a job for Spintron!.. (with a valve heated above 100° C. of course)

Re: Valve stem seals crushed, LS7. More spring?

i guess if the test was started with chilled components and the valve temp monitored, the solid vs. liquid Na valve motion could even be compared in one pull...

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

Re: Valve stem seals crushed, LS7. More spring?

I'll bet it could. Can you imagine an OEM giving green lights to that kind of testing for a perf catalog product?MadBill wrote:i guess if the test was started with chilled components and the valve temp monitored, the solid vs. liquid Na valve motion could even be compared in one pull...

Re: Valve stem seals crushed, LS7. More spring?

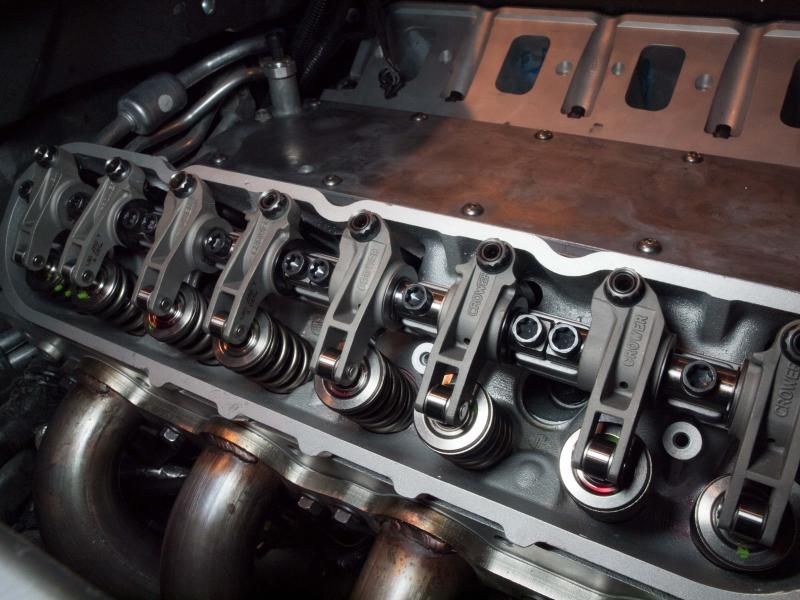

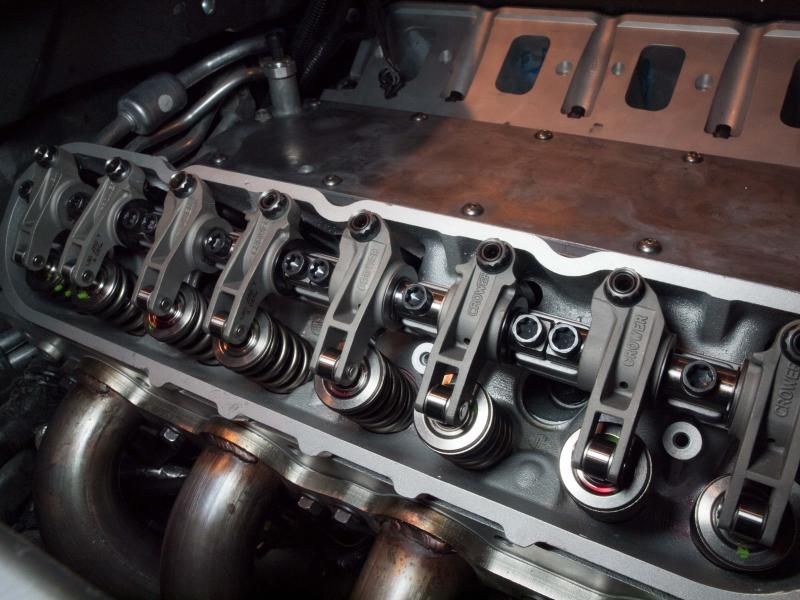

quote="mdrew"]The contact was about as good as one could expect. Here are a couple pics after full engine rotation with hydraulic lifters modified to act as solid lifters.

[/quote]

[/quote]

Hi mdrew,

I hate to argue but I will. Geometry has nothing to do with valve tip motion especially when using a roller tip. For me it is not even close. Forget about how it averages across the tip and concern yourself about what it is trying to achieve.

The beginning of a variable ratio also has less pressure and motion at the beginning of its' movement. Concern yourself with correct placement at maximum pressure, adjust fulcrum height, IF you are fixed to a certain fulcrum distance and can adjust your parts as best as you can, if you can. If you have the ability to alter both fulcrum distances, size of valve tip roller and distance from there and achieve "theoretical" ratio, pushrod cup and angle you will have the world. This is the suck in the aftermarket.

As to your seal crushing, obviously something is way out of control and that is what you are trying to find. It seems fairly simple to fix.

Obviously hard to tell from a picture but to me the fulcrum area is way to high for amount of lift for the valve. I know the LS7 doesn't have an easy way to fix that if you err.

[/quote]

[/quote]Hi mdrew,

I hate to argue but I will. Geometry has nothing to do with valve tip motion especially when using a roller tip. For me it is not even close. Forget about how it averages across the tip and concern yourself about what it is trying to achieve.

The beginning of a variable ratio also has less pressure and motion at the beginning of its' movement. Concern yourself with correct placement at maximum pressure, adjust fulcrum height, IF you are fixed to a certain fulcrum distance and can adjust your parts as best as you can, if you can. If you have the ability to alter both fulcrum distances, size of valve tip roller and distance from there and achieve "theoretical" ratio, pushrod cup and angle you will have the world. This is the suck in the aftermarket.

As to your seal crushing, obviously something is way out of control and that is what you are trying to find. It seems fairly simple to fix.

Obviously hard to tell from a picture but to me the fulcrum area is way to high for amount of lift for the valve. I know the LS7 doesn't have an easy way to fix that if you err.

Heat is energy, energy is horsepower...but you gotta control the heat.

-Carl

-Carl

-

pamotorman

- Guru

- Posts: 2802

- Joined: Thu Mar 06, 2014 11:55 pm

- Location:

Re: Valve stem seals crushed, LS7. More spring?

here is the tool I used to check pushrod length

You do not have the required permissions to view the files attached to this post.

Re: Valve stem seals crushed, LS7. More spring?

Hu? I'm not following you.... It doesn't matter if the rocker pushing down on the stem at its center, the entire cycle? Why on earth would that not matter? Or are you talking about mid-lift?In-Tech wrote:

Hi mdrew,

I hate to argue but I will. Geometry has nothing to do with valve tip motion especially when using a roller tip. For me it is not even close. Forget about how it averages across the tip and concern yourself about what it is trying to achieve.

The beginning of a variable ratio also has less pressure and motion at the beginning of its' movement. Concern yourself with correct placement at maximum pressure, adjust fulcrum height, IF you are fixed to a certain fulcrum distance and can adjust your parts as best as you can, if you can. If you have the ability to alter both fulcrum distances, size of valve tip roller and distance from there and achieve "theoretical" ratio, pushrod cup and angle you will have the world. This is the suck in the aftermarket.

As to your seal crushing, obviously something is way out of control and that is what you are trying to find. It seems fairly simple to fix.

Obviously hard to tell from a picture but to me the fulcrum area is way to high for amount of lift for the valve. I know the LS7 doesn't have an easy way to fix that if you err.

With the OEM setup, there is not an elegant way to adjust rocker fulcrum. Not like its sibling LS engines that use a base plate. The LS7 has pedestals. The Crower system is similar to other rocker systems (T&D, Jesel, Comp). The amount of pedestal milling is based on total lift requirements. A gauge is included in the kit to calculate / measure amount of milling needed to achieve optimum fulcrum height. Shims are then added, as needed under the base plate for fine tuning the rocker roller to the stem tip.

Once I get a camshaft spec'd, I will obviously get a spring recommendation from the grinder, but I'll also reach out to PAC and get their recommendation as well. I'll have to pull a few springs after a couple redline revs to see if the problem persists.

Re: Valve stem seals crushed, LS7. More spring?

Once you deviate much from something akin to 'mid-lift' geometry, a high lift cam starts to produce a ton of sweep at just the wrong time...

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

Re: Valve stem seals crushed, LS7. More spring?

proper geometry will get the sweep as narrow as possible

but

not necessarily centered over the valve stem

If too far off center- roller coming off the edge or too close to edge or standard rocker with too much angle you have to make a mechanical adjustment

lash caps/ keepers (the valve does not really care but it wants the force as straight down as possible and with standard rockers with the least side thrust as possible both top and bottom of lift

rocker with a longer (usually) or shorter (sometimes) arm

move the fulcurm-, move the shaft

offset fulcrums- shafts whatever

change the angle of the valve slightly to move the tip and redo valve job

a little less lift- which may allow better over the nose action anyway

now order pushrods

screwing with the pushrod length to move the contact line will come back and bite you big time

what Bill said

but

not necessarily centered over the valve stem

If too far off center- roller coming off the edge or too close to edge or standard rocker with too much angle you have to make a mechanical adjustment

lash caps/ keepers (the valve does not really care but it wants the force as straight down as possible and with standard rockers with the least side thrust as possible both top and bottom of lift

rocker with a longer (usually) or shorter (sometimes) arm

move the fulcurm-, move the shaft

offset fulcrums- shafts whatever

change the angle of the valve slightly to move the tip and redo valve job

a little less lift- which may allow better over the nose action anyway

now order pushrods

screwing with the pushrod length to move the contact line will come back and bite you big time

what Bill said

Re: Valve stem seals crushed, LS7. More spring?

Yah, I get all that. What I don't get, is why the pictures of the witness marks I posted earlier are being called into question. The pics are after full engine rotation, and the witness mark is dead center, and extremely narrow. That in itself tells me the rocker is pushing straight down on the tip, and it is not side loading the stem.

Re: Valve stem seals crushed, LS7. More spring?

Wanted to add a little to the discussion. Currently using the stock rocker arms and I'm having similar results with guide wear as mdrew did on his second setup. My cam is quite a bit smaller at 234/240 and .610/.623. Wear patterns weren't terrible but certainly showed signs of side loading of the valve with taper of about .0025" on the spring side of the guides(bronze). I do rough my car up a bit more though with at least half of those miles at high rpm on a road course. Currently looking at a full shaft setup trying to decide between the Crowers in this discussion and a set of T&D's.

-

allencr267

- Pro

- Posts: 362

- Joined: Wed Nov 07, 2012 6:28 pm

- Location: Tallahassee Florida USofA

Re: Valve stem seals crushed, LS7. More spring?

Any pics of the alleged victim stem seals?mdrew wrote:...pictures of the witness marks...