Strange Magic wrote:I wouldn't give Mobil 1 oil to my worst enemy. It's just my thoughts on a product that had much better days years ago. To be blunt, it's shit! Just my humble opinion.

Its not all crap. You just have to know which are, and which aren't. They along with all the other oil manufactures/marketers were required to make less than favorable changes to their oils to meet certain specs. Some Mobil 1 oils like their 5/30 is less than it could be. Don't blame them, blame the EPA and ILSAC(auto manuf). I wouldn't run Mobil 1n or ANY GF5 certified oil in a lawn mower, let alone a performance engine specially once its out of warranty.

I run Mobil 1 in a blown BBC in an edurance boat, and never had a single issue. But then I am not trying to run some oil dictated by the EPA and auto manufs.

Cedarmachine wrote:Run a true performance oil with an additive package including zinc. This problem will most likely go away.

There are still places in engines where zinc is required. Unless you put a roller rocker on the engine, this is one place that needs help from the oil. Even then, a roller rocker only transfers the metal to metal load to a axle pin, but it helps.

I use Synergen products. Their oil additive or oil will eliminate this problem. If it doesn't, there is oil system issue.

Yep. No matter what the auto manufactures think, they did not rid the entire engine of parts and places that an GOODm anti wear agent is needed. This is just one of those places. I laugh when people look at their mains and rod bearings and judge their oil by that. Wesson oil would work fine for a pressurized plain bearing. Castor bean vegetable oil ruled Indy during the Offy years.

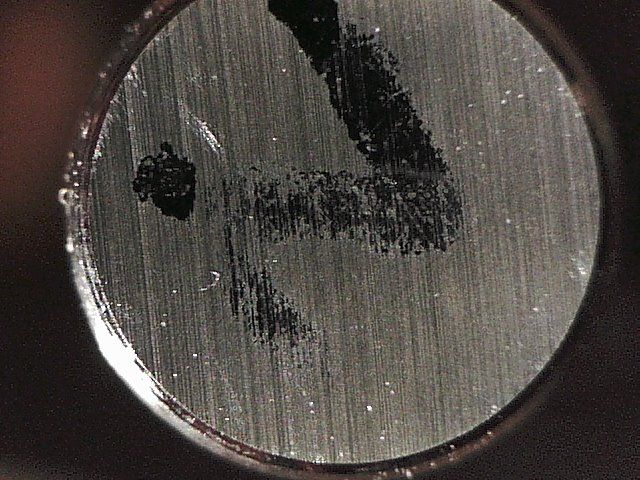

What you are seeing here is perfect example of an oil that cannot do the job it is required to do. I have no doubt the problems with the guides is partly due to the same thing. JMO

crazyman wrote:As cast rockers and rough cut valve tips would be my guess.. Must we tear apart a brand new engine to "freshen it up" GM?

As far as coil bind.. I'm definitely not a professional, but when was the last time you pulled out your feeler gauge and saw how thin even 0.100 is? Imagine it at rpm crashing coils while oscillating multiple times per cycle..

The only way you can coil bind a spring that has .050-.060 clearance in a running engine is if the valve is lofted off the nose. If thats the case, and it is entirely possible, then he has big spring issues. But if this is a STOCK engine as he posted, I doubt that is the problem unless he is running it into valve float.

I would not be at all surprised to see the same exact results from spring hysteresis/surge/harmonics. But not with a stock cam that wasn't subjected to valve float repeatedly.