Personally i have mostly been looking at the 2.8l stroked version of the m20, however there is a lot of info in the thread that is still relevant to all the other displacements.

Nearly every area of this engine is being looked at with the aim to find a few tricks and simple modifications that can bring this engine up to spec without spending a fortune on parts, custom parts would be the nice easy way out for a lot of things but the idea is more to do what we can with what we have.

(and anyway the simple answer would be to spend $5k and fit an M3 engine).

The specs of the engine in question:

84mm bore

84mm stroke (originally 75mm on the 2.5l)

Aiming for ~11:1 CR

Hp target is at least 250hp@6500 with the best torque curve possible,

One of the big issues is the rod/storke ratio, a quick and simple way of building the 2.8 is to use the 130mm connecting rods and have the block decked by 0.5mm, This leaves a r/s ratio of 1.54:1

If i stick with the stock 135mm rod then i am looking at 1.607:1 which is a bit nicer.

Trouble being this either requires custom pistons (out due to the cost over here) or a modified stock piston, a few ways have been looked at and discussed as how to go about this and its certainly a viable option.

Currently i am looking at using the whole M52B28 reciprocating assembly with the piston and possible the chamber modified to suit each other.

The details of the head and piston are as follows:

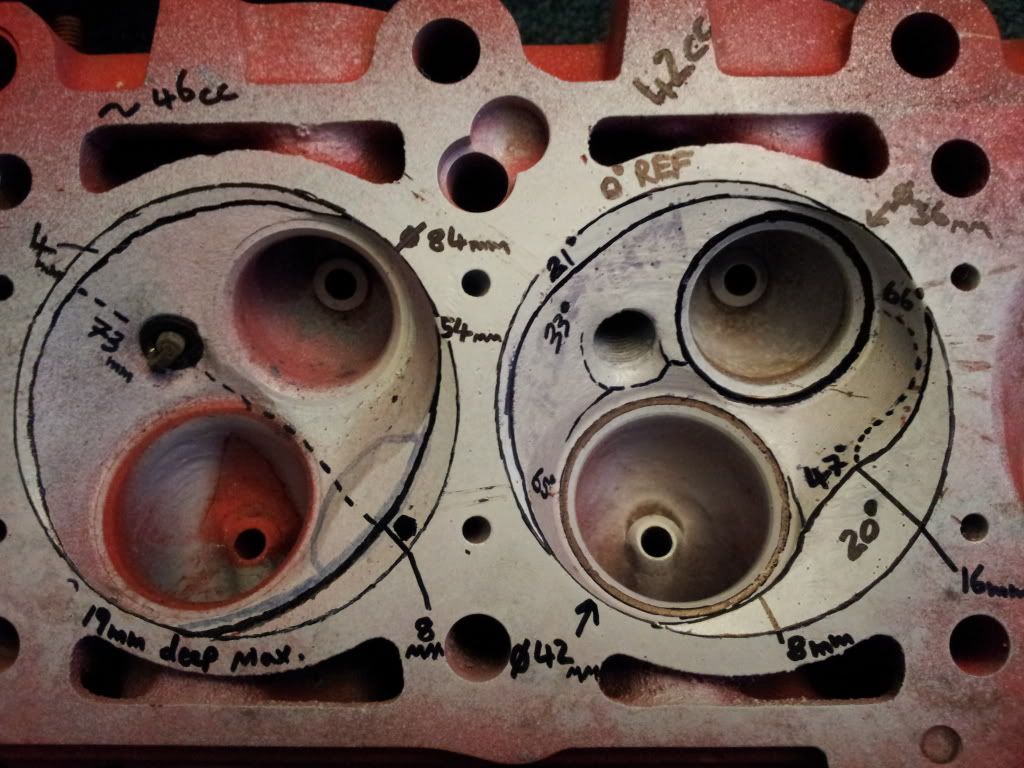

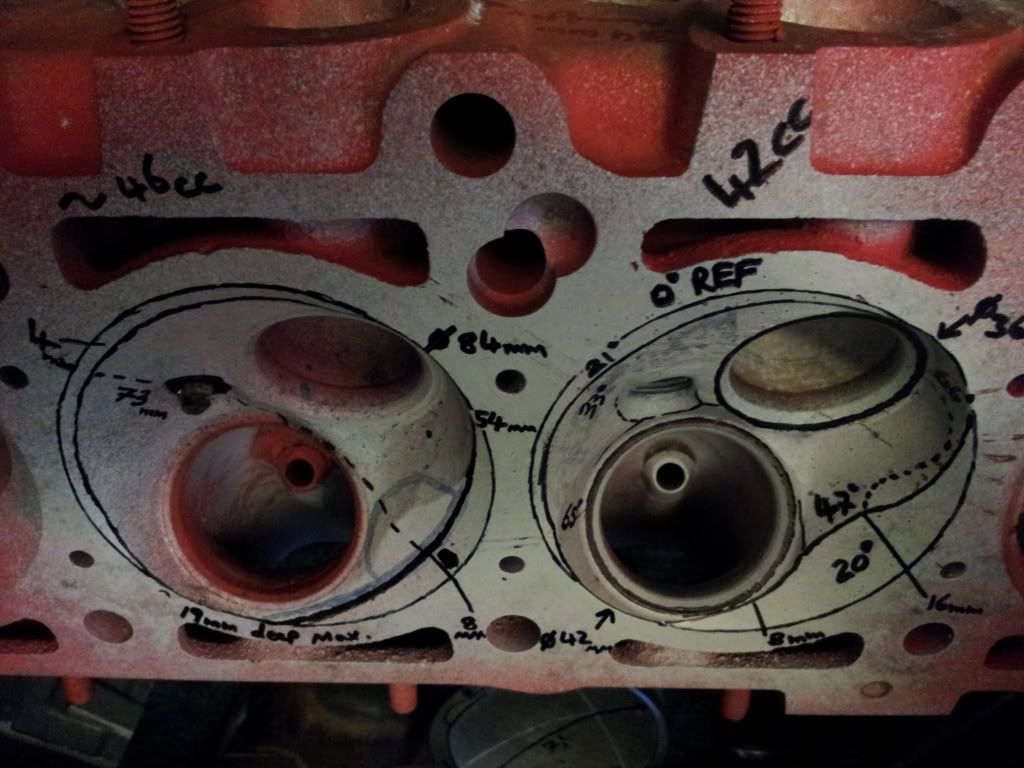

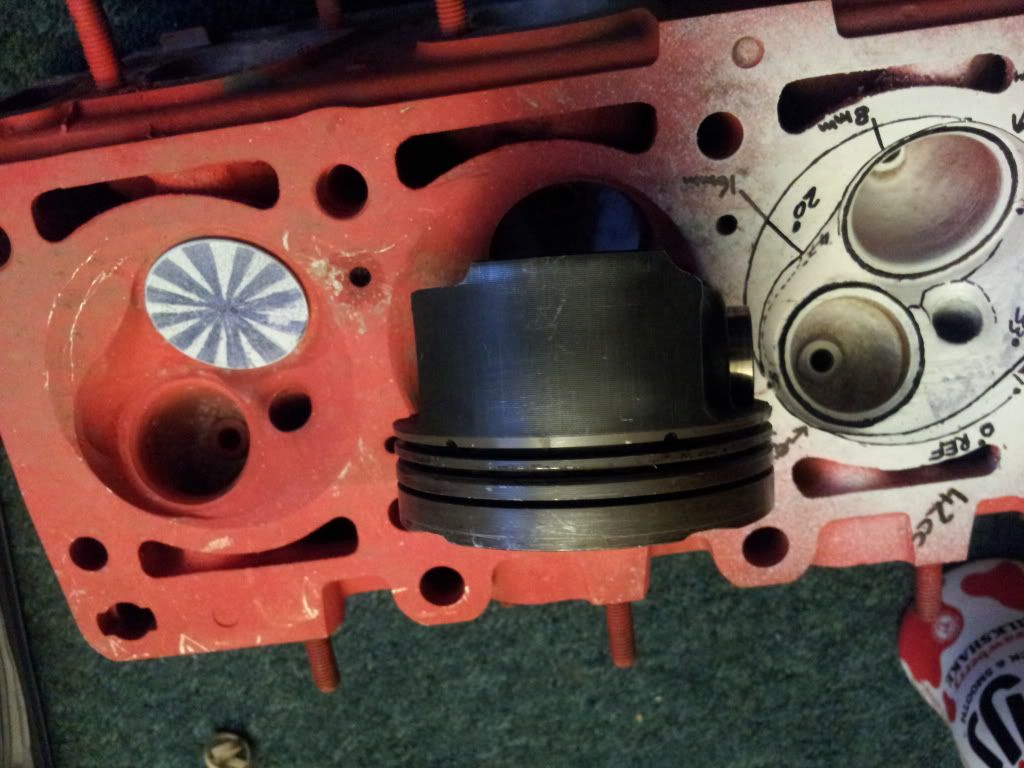

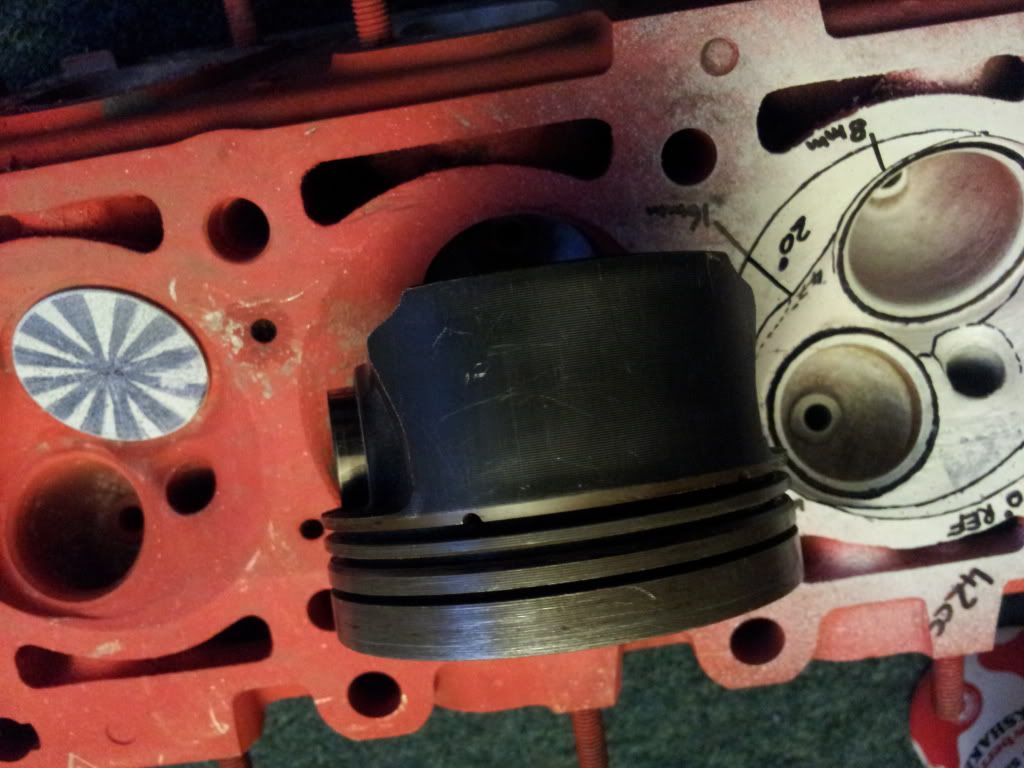

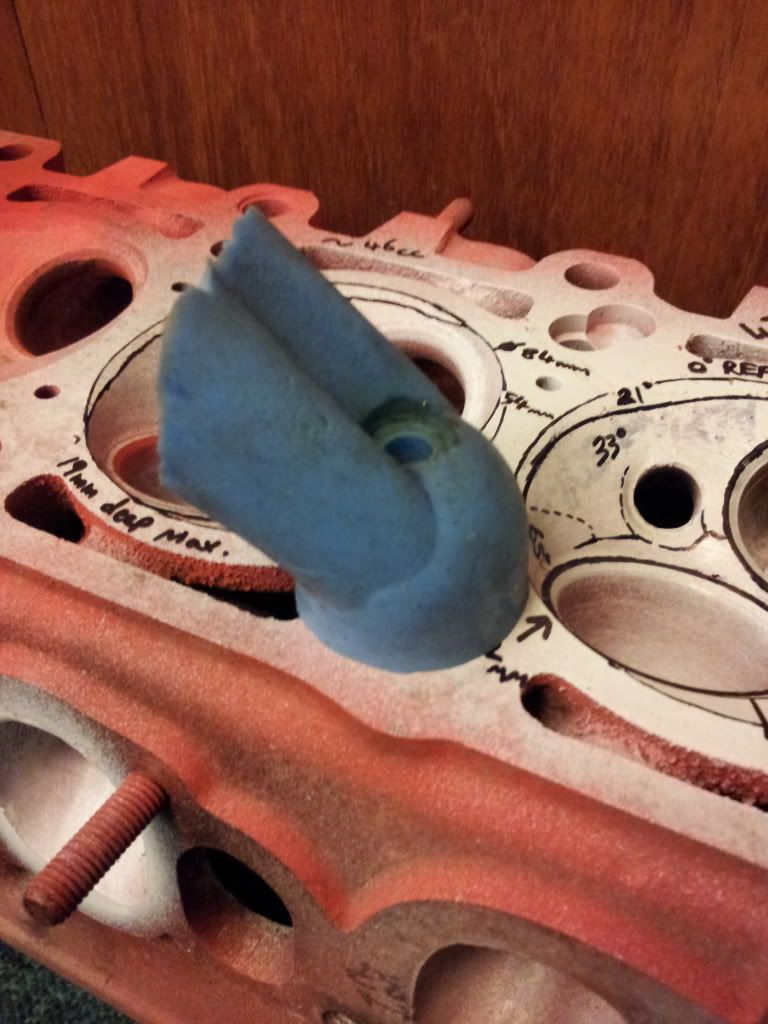

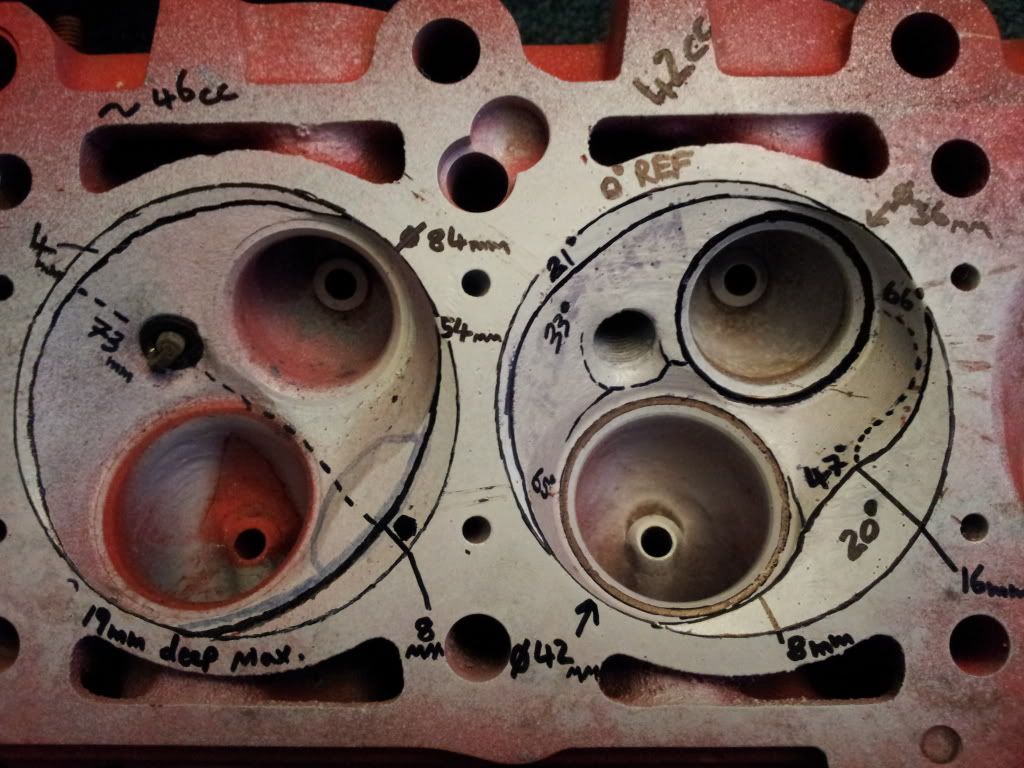

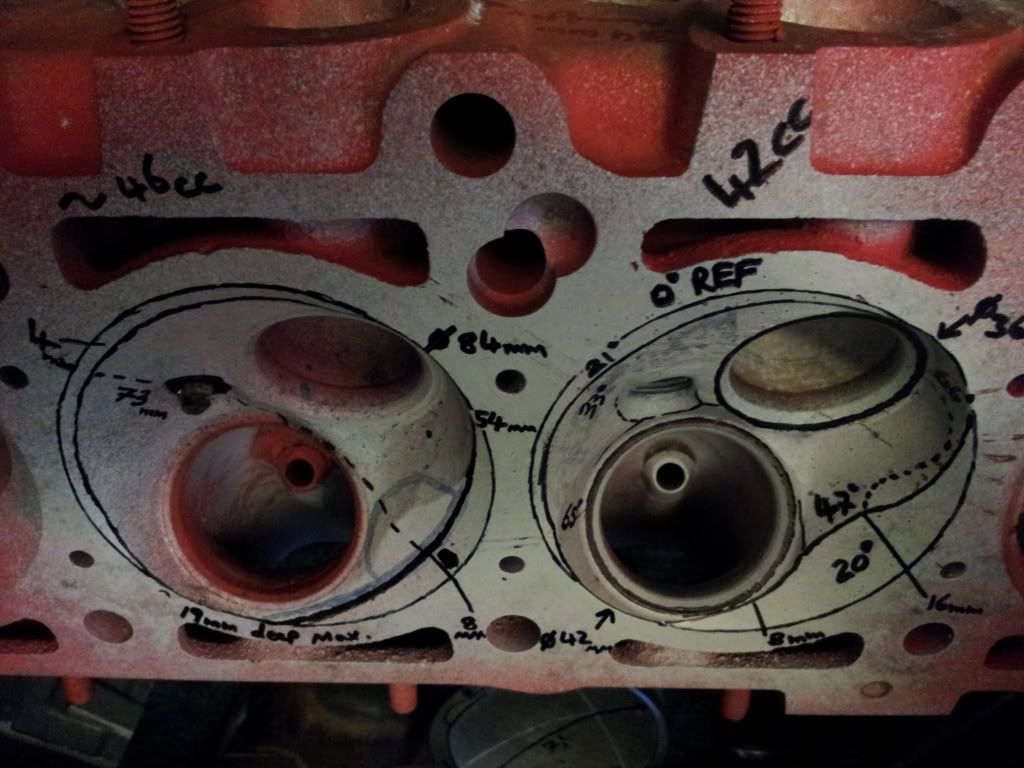

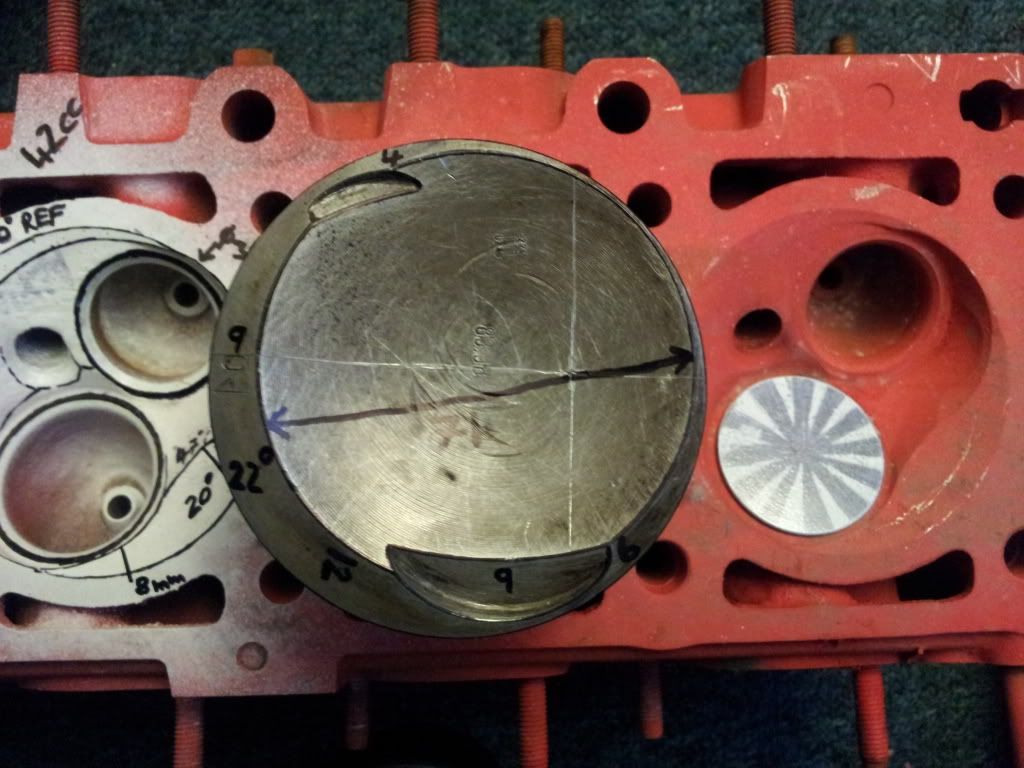

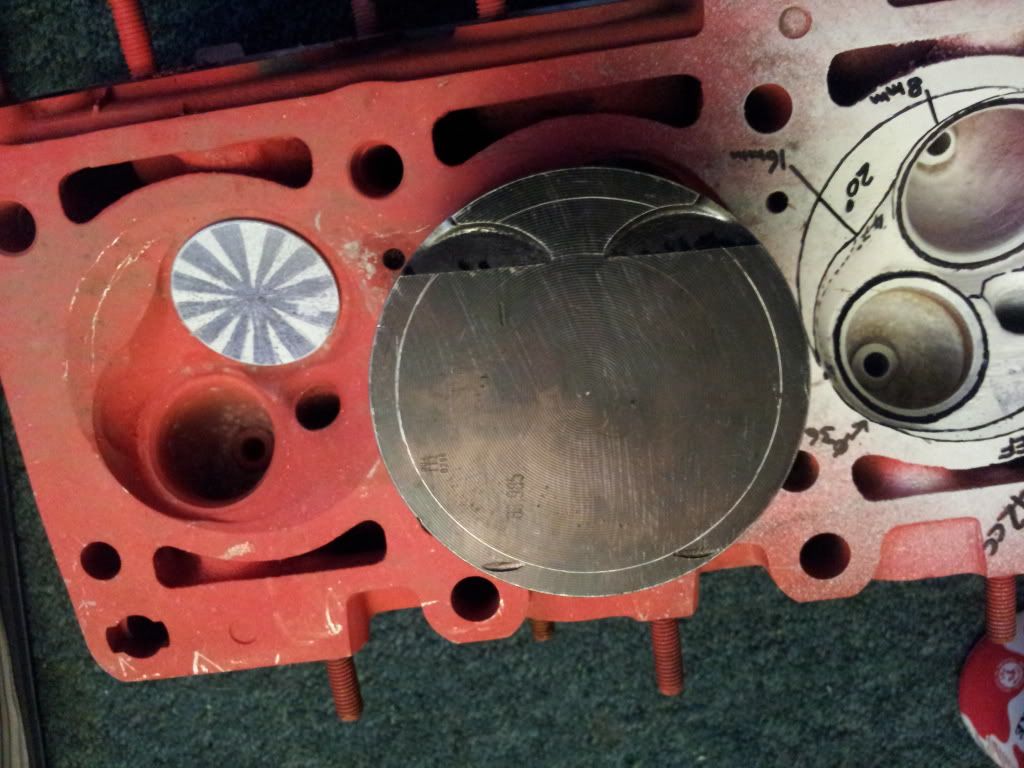

The photos above show the standard chamber on the right with the contours highlighted in black and most of the dimensions written on. The left is a proposed chamber modification which i will come back to.

The standard M20B25 (B25 is the displacement code) Piston is a funny one and has a raised squish band with a bowl.

Sticking with this shape would be great but impractical without removing 4.5mm from the top of that piston of going custom.

They are also heavy old slugs and no where near any of the modern designs.

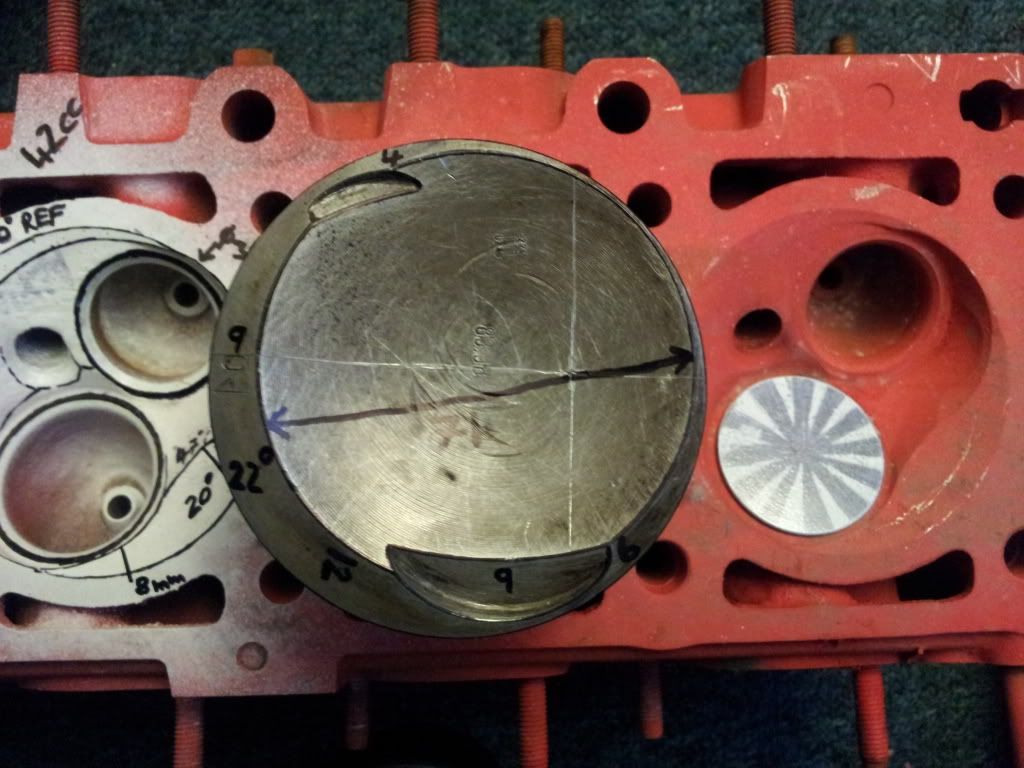

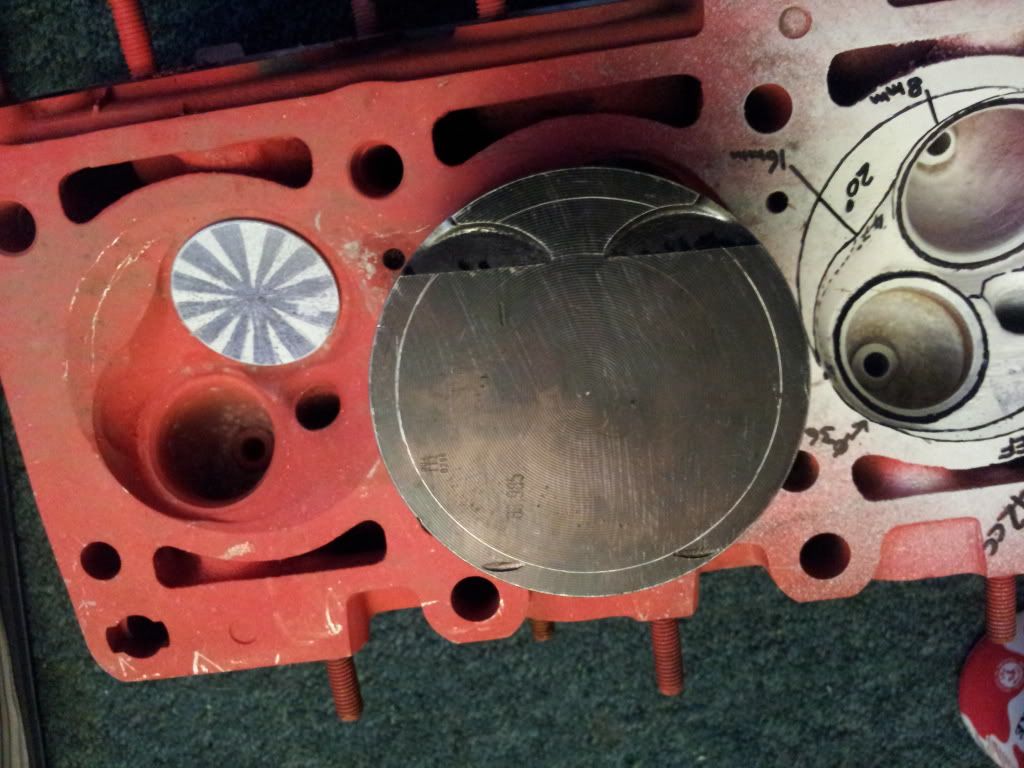

Which is where the M52B28 piston is great for a stock item.

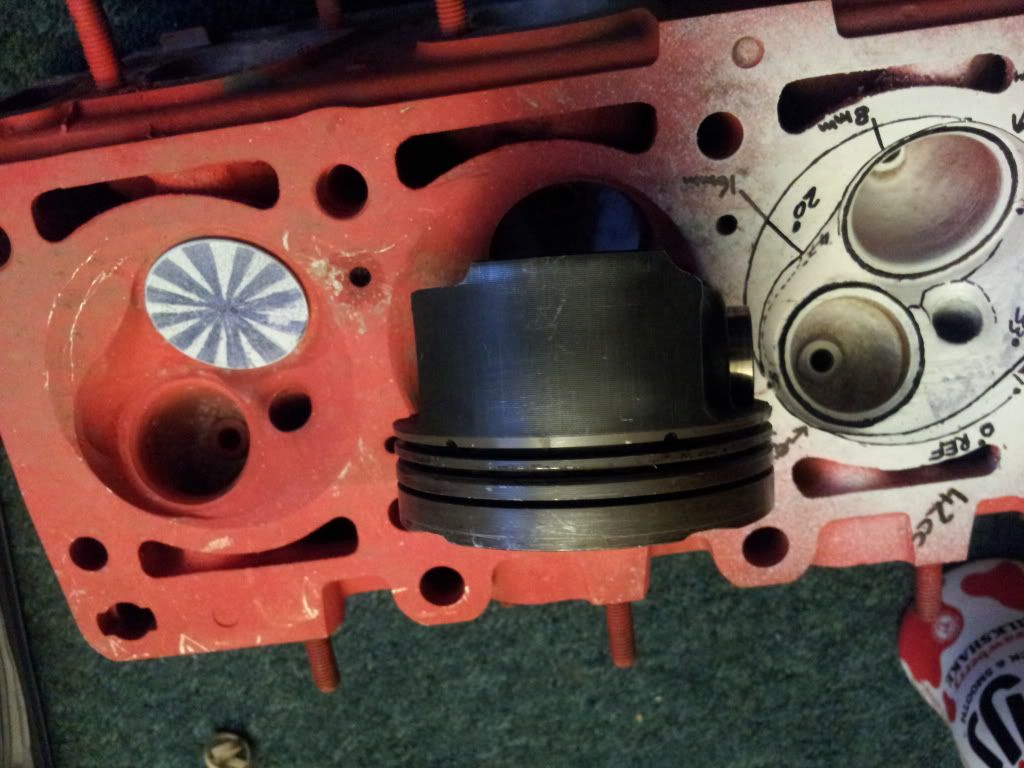

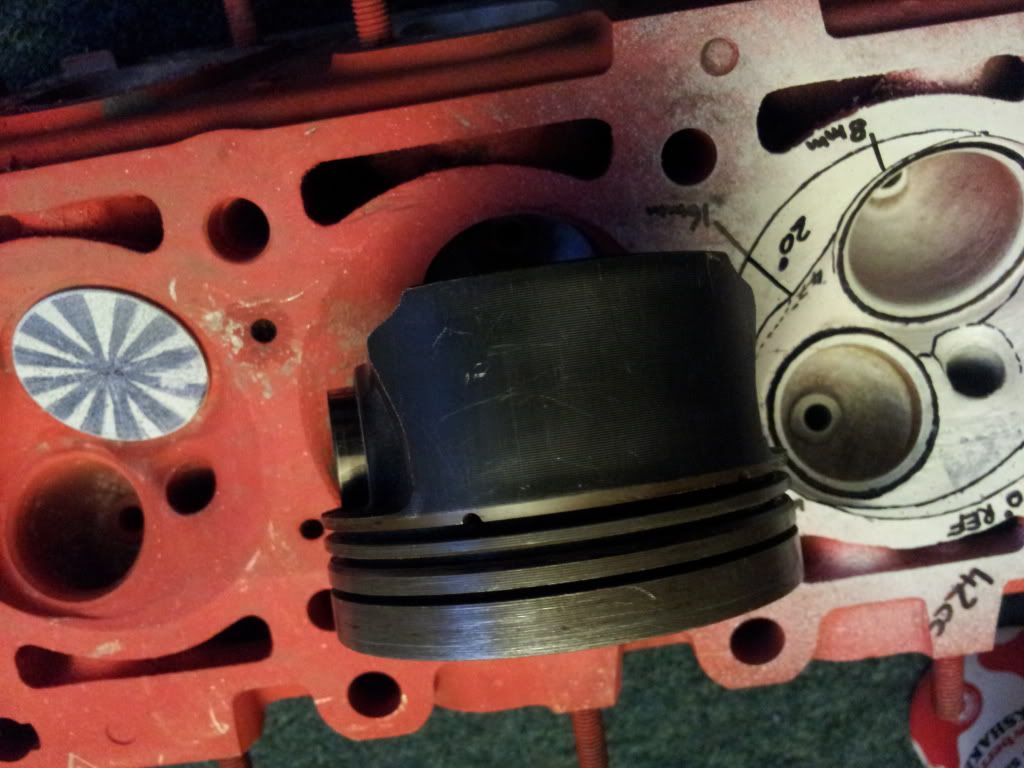

For a standard piston this one is pretty good, slightly asymmetric skirts, anti friction coating, light slipper design and 2mm offset pin and nice tight ring pack.

The current proposal is to use this piston with the edge marked by the circle scribed on the top cut down at around 21* to provide a 5.5mm squish band. (valve cut outs have been successfully cut into these for the 2V M20 in this thread :

http://www.e30tech.com/forum/showthread ... 38&page=17 )

This will however mean the piston doesn't quite match the head, something i am not keen on.

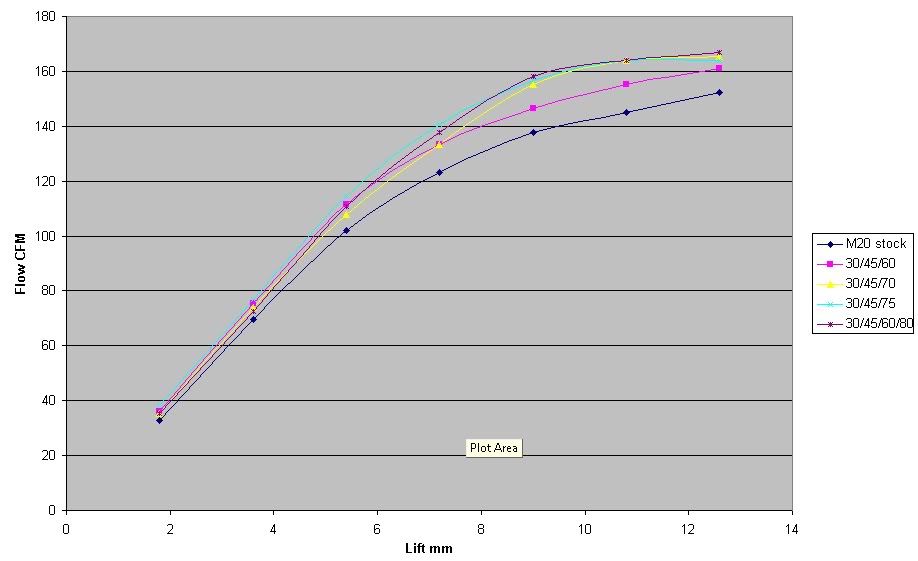

The Idea for the head is to machine the extra part of the quench pad out of the chamber as seen on the left hand chamber in the pictures above.

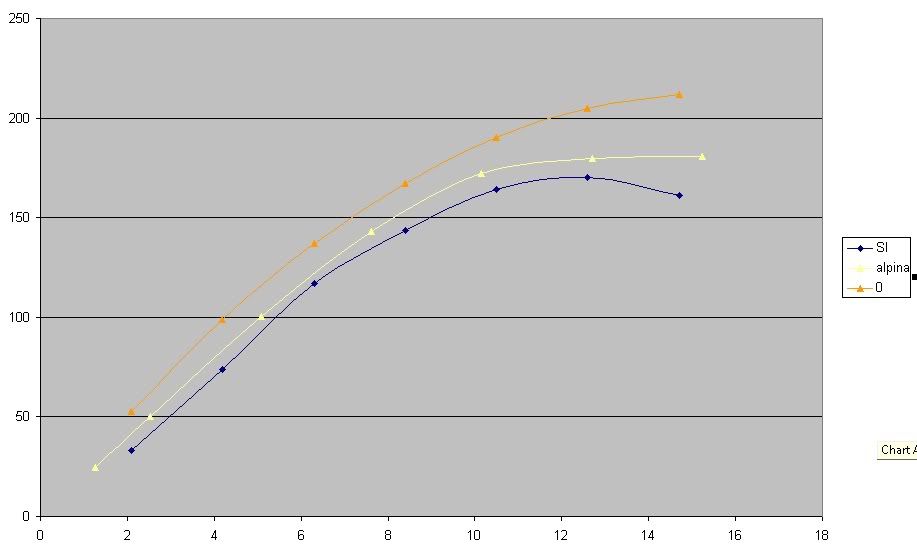

This would result in a 11.5:1 CR and is similar to a modification done by Alpina in the 1980s however they produced a full hemi with no squish and used the standard Piston crown profile

On the left hand chamber above there is a line marked around the squish pad showing the furthest distance from the plug.

On the stock chamber the longest flame path is 54mm directly over the exhaust valve.

It would be good to hear what the collected knowledge on here thinks of altering this chamber in this manner.