main bolt to stud, line hone?

Moderator: Team

-

speedphreake

- New Member

- Posts: 33

- Joined: Tue Jan 08, 2008 8:07 pm

- Location:

main bolt to stud, line hone?

On a sbc 4 bolt block, would changing from stock bolts to studs require a line hone?

Thanks in advance....

Thanks in advance....

-

Keith Morganstein

- Guru

- Posts: 5566

- Joined: Sun Feb 19, 2006 10:19 am

- Location: MA

Re: main bolt to stud, line hone?

Yes, but you have very little to gain (if anything) by installing studs on a factory four bolt block.speedphreake wrote:On a sbc 4 bolt block, would changing from stock bolts to studs require a line hone?

Thanks in advance....

Automotive Machining, cylinder head rebuilding, engine building. Can't seem to quit

-

Ron Golden

- Expert

- Posts: 763

- Joined: Mon Dec 25, 2006 7:09 pm

- Location: Kansas City, MO

-

CNC BLOCKS

- Guru

- Posts: 4653

- Joined: Thu Jul 01, 2004 6:34 am

- Location: NORTHEAST

- Contact:

Re: main bolt to stud, line hone?

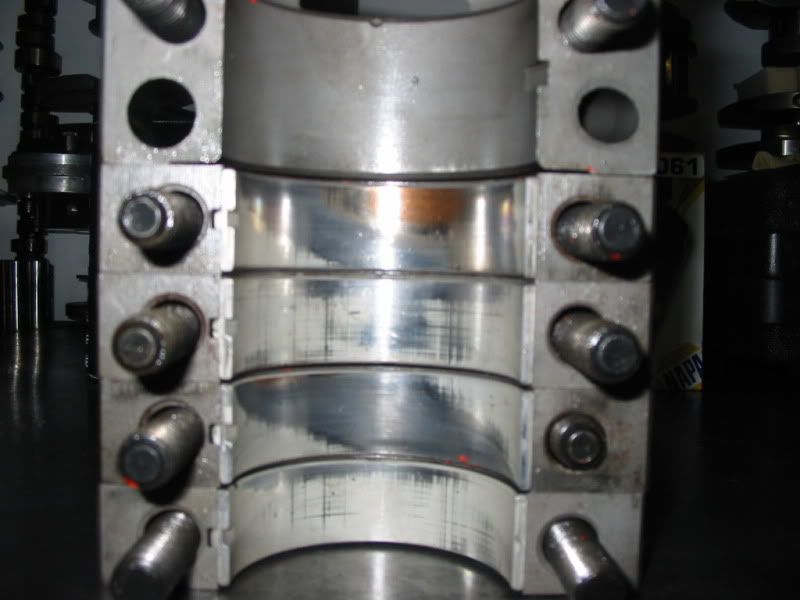

Any SBC should be line honed if its going to be used in a performance application and going to studs would change the clamping force and may change the housing diameter, If your using an ARP stud kit read the instructions.speedphreake wrote:On a sbc 4 bolt block, would changing from stock bolts to studs require a line hone?

Thanks in advance....

Here is a pic of a 327 with 400 miles on the rebuild and its a perfect example why we line hone.

[/QUOTE]

[/QUOTE]Website is up and running

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

-

xXDaveyJonesXx

- New Member

- Posts: 30

- Joined: Mon Aug 16, 2010 6:00 am

- Location: Anchorage, AK

-

Keith Morganstein

- Guru

- Posts: 5566

- Joined: Sun Feb 19, 2006 10:19 am

- Location: MA

Re: main bolt to stud, line hone?

Not just performance applications either. Many just need a line hone after so many years of service.CNC BLOCKS wrote:Any SBC should be line honed if its going to be used in a performance application and going to studs would change the clamping force and may change the housing diameter, If your using an ARP stud kit read the instructions.speedphreake wrote:On a sbc 4 bolt block, would changing from stock bolts to studs require a line hone?

Thanks in advance....

ARP main studs may be very good fasteners, but I see the most cap fretting on engines that have been in service with them. I don't think they clamp as well as the OEM bolts. Stock SBC caps will break before you have to worry about the fasteners. The 2842 caps are better, but most SBC's just have the regular iron caps.

Automotive Machining, cylinder head rebuilding, engine building. Can't seem to quit

-

CNC BLOCKS

- Guru

- Posts: 4653

- Joined: Thu Jul 01, 2004 6:34 am

- Location: NORTHEAST

- Contact:

Re: main bolt to stud, line hone?

KeithKeith Morganstein wrote:Not just performance applications either. Many just need a line hone after so many years of service.CNC BLOCKS wrote:Any SBC should be line honed if its going to be used in a performance application and going to studs would change the clamping force and may change the housing diameter, If your using an ARP stud kit read the instructions.speedphreake wrote:On a sbc 4 bolt block, would changing from stock bolts to studs require a line hone?

Thanks in advance....

ARP main studs may be very good fasteners, but I see the most cap fretting on engines that have been in service with them. I don't think they clamp as well as the OEM bolts. Stock SBC caps will break before you have to worry about the fasteners. The 2842 caps are better, but most SBC's just have the regular iron caps.

We line hone just about every block that comes through the door and stud do have much better clamping force over a bolt seeing that a stud has a fine thread at the top.

Most shops can only check bore demension and can not check alignment issues and thats where most problems lie.CHT wrote:It costs nothing to check!

Website is up and running

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

-

Keith Morganstein

- Guru

- Posts: 5566

- Joined: Sun Feb 19, 2006 10:19 am

- Location: MA

Re: main bolt to stud, line hone?

The best way to check the mainline is to just align hone it. Done, good, move on. It's not an expensive or time consuming job. You have piece of mind knowing every thing is good.

You can get a rough indication of if a block DEFINITELY needs an align hone by laying a straight edge across the main saddles. If you can see daylight or slide a feeler under it DEFINITELY needs it. That is not an all encompassing test by any means, but if it fails that test, you know it has to be done. Still, I would just rather do it than worry about it.

Main studs - You know I drank the Koolaid and read the ARP literature and studded a whole bunch of engines. I understand the theory, the fine thread etc.. Some I still stud, but I see so much more cap fretting on studded racing engines. My unscientific opinion is that the main bolt stretches just right and actually does a better job holding the cap down.

You can get a rough indication of if a block DEFINITELY needs an align hone by laying a straight edge across the main saddles. If you can see daylight or slide a feeler under it DEFINITELY needs it. That is not an all encompassing test by any means, but if it fails that test, you know it has to be done. Still, I would just rather do it than worry about it.

Main studs - You know I drank the Koolaid and read the ARP literature and studded a whole bunch of engines. I understand the theory, the fine thread etc.. Some I still stud, but I see so much more cap fretting on studded racing engines. My unscientific opinion is that the main bolt stretches just right and actually does a better job holding the cap down.

Automotive Machining, cylinder head rebuilding, engine building. Can't seem to quit

-

Dodge Freak

- Guru

- Posts: 1711

- Joined: Sun Oct 21, 2007 6:56 pm

- Location:

Re: main bolt to stud, line hone?

Only on Speedtalk I would see somebody posting something bad about using main studs and think there might be something to it!

-

CNC BLOCKS

- Guru

- Posts: 4653

- Joined: Thu Jul 01, 2004 6:34 am

- Location: NORTHEAST

- Contact:

Re: main bolt to stud, line hone?

I have to ask are you machining your blocks and balancing your rotators?? We have built a lot of circle track engines for years and have not seen any fretting of main caps. I would have to say something is going on here and it needs to be addressed if your seeing caps moving!!!Keith Morganstein wrote:

Main studs - You know I drank the Koolaid and read the ARP literature and studded a whole bunch of engines. I understand the theory, the fine thread etc.. Some I still stud, but I see so much more cap fretting on studded racing engines. My unscientific opinion is that the main bolt stretches just right and actually does a better job holding the cap down.

Website is up and running

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

http://hinksonautomotive-cncblocks.com/

Machine shop tour

http://hinksonautomotive-cncblocks.com/shop-tour/

Monthly Specials

http://hinksonautomotive-cncblocks.com/specials/

55MM babbit cam bearings with 1 hole

- 427Impaler

- New Member

- Posts: 16

- Joined: Fri Aug 13, 2010 2:46 pm

- Location: Maple Ridge BC

Re: main bolt to stud, line hone?

Man, this site is always a good read. I would not have expected to read this thread and find most builders recommend using standard fasteners, I apparently bought into the whole "studs are better" propaganda. I have always studded and line honed.

Here is a newby question, what are you reffering to when you say "cap fretting"?

Bob

Here is a newby question, what are you reffering to when you say "cap fretting"?

Bob

-

Keith Morganstein

- Guru

- Posts: 5566

- Joined: Sun Feb 19, 2006 10:19 am

- Location: MA

Re: main bolt to stud, line hone?

CNC BLOCKS wrote:I have to ask are you machining your blocks and balancing your rotators?? We have built a lot of circle track engines for years and have not seen any fretting of main caps. I would have to say something is going on here and it needs to be addressed if your seeing caps moving!!!Keith Morganstein wrote:

Main studs - You know I drank the Koolaid and read the ARP literature and studded a whole bunch of engines. I understand the theory, the fine thread etc.. Some I still stud, but I see so much more cap fretting on studded racing engines. My unscientific opinion is that the main bolt stretches just right and actually does a better job holding the cap down.

Carl, of course!!! align honed with sunned equipment and balanced. Majority of blocks blueprinted with BHJ fixtures. The engines I see the most fretting on is higher HP drag race engines and pulling engines. The ones with NOS are the worst.

For the other guy: When you remove a main or rod cap and see a little lump of metal on one side and a little crater on the mating piece, that is evidence of fretting. Movement of the cap that causes micro welding and the metal transfer that you see.

Automotive Machining, cylinder head rebuilding, engine building. Can't seem to quit

- Wolfplace

- Guru

- Posts: 3580

- Joined: Fri Sep 24, 2004 10:39 pm

- Location: Mendocino County, Northern CA

- Contact:

Re: main bolt to stud, line hone?

Not saying there is anything wrong with GM fasteners,, they are pretty stout but with regard to most builders recommending them over studs I know I don't427Impaler wrote:Man, this site is always a good read. I would not have expected to read this thread and find most builders recommend using standard fasteners, I apparently bought into the whole "studs are better" propaganda. I have always studded and line honed.

Here is a newby question, what are you reffering to when you say "cap fretting"?

Bob

My experience mirrors that of Carl's with regard to studs.

The caps do not move,, or I should say do not appear to move as much with studs

Assuming the studs are correctly tightened

Fretting is the caps moving & it looks almost like someone was welding on them

Carl has some excellent pics he has put up in the past of fretting, maybe he will put them up again,,,

Mike

Lewis Racing Engines

4axis CNC block machining

A few of the cars I have driven & owned

A tour of my shop

The Dyno

And a few pics of the gang

"Life is tough. Life is even tougher if you're stupid"

John Wayne

Lewis Racing Engines

4axis CNC block machining

A few of the cars I have driven & owned

A tour of my shop

The Dyno

And a few pics of the gang

"Life is tough. Life is even tougher if you're stupid"

John Wayne

- 427Impaler

- New Member

- Posts: 16

- Joined: Fri Aug 13, 2010 2:46 pm

- Location: Maple Ridge BC

Re: main bolt to stud, line hone?

Thanks all for clarifying exactly what fretting is. Nice to know I can ask a question which might seem simple and not get plowed!

Many years ago we built a 2 bolt street strip 427 that exhibited some evidence of cap walk on the bearings, we moved to a 4 bolt studded block since then and have had no signs since.

Thanks again guys,

Bob

Many years ago we built a 2 bolt street strip 427 that exhibited some evidence of cap walk on the bearings, we moved to a 4 bolt studded block since then and have had no signs since.

Thanks again guys,

Bob