storm vulcan #85 surfacer

Moderator: Team

Re: storm vulcan #85 surfacer

I was about to pull the trigger on an 85B that Gale Banks had listed on ebay a few years ago for $5k that had all the tooling and gear reduction motors on it. I always thought that was the machine I wanted myself. I had a few days to make a decision and after seeing all the things that the 85s needed to have checked/maintained and then the multi cutter sharpening, I went with a SV RT17Y with the Jamison CBN wheel conversion instead(1 simple insert). It was not maintained real well at the auto parts store it was from and took some work to get the table cleaned up and a few other things- like sheet metal repairs- but after some work and recutting the risers on my mill and building my own True Deck fixture is does the trick real nice for me. I can hold decks .001" end to end and either side no problem. Variable hydraulic feed std on these machines, only downside is the 1050 rpm head it has vs the 3000+ of newer machines.

Pete Graves

CPMotorworks,Inc.

Custom Engine Machining

Cylinder Head Fixture for Vertical / Surfacing Mills since 2008

CPMotorworks,Inc.

Custom Engine Machining

Cylinder Head Fixture for Vertical / Surfacing Mills since 2008

Re: storm vulcan #85 surfacer

The 85B has got to the best, most trouble-free surfacer there is. I have one that was manufactured in 1966 that still works great. I have been running the same cutter head for about 25 years. I just added the variable speed feed to it and speeded the cutter wheel up a bit. It does a great job but the bits are dull and it won't cut a lot of stock on each cut. Jamison Equipment in Iowa is offering a set of adjustable, replacable tip cutters for about $1100, that is the next thing I'm going to do. Hoping to buy another machine and make 2 sets by only installing 8 per machine. I saw a picture of an 85EL and it looks like they spaced the cutters further apart and installed fewer of them. You won't go wrong in buying one of these machines. If anyone needs a list of parts to put the variable speed on a machine, just send an email to me. I can also send pictures, it's a simple mod, though not real cheap. Bought some of the parts off EBay and saved a few bucks.

Re:

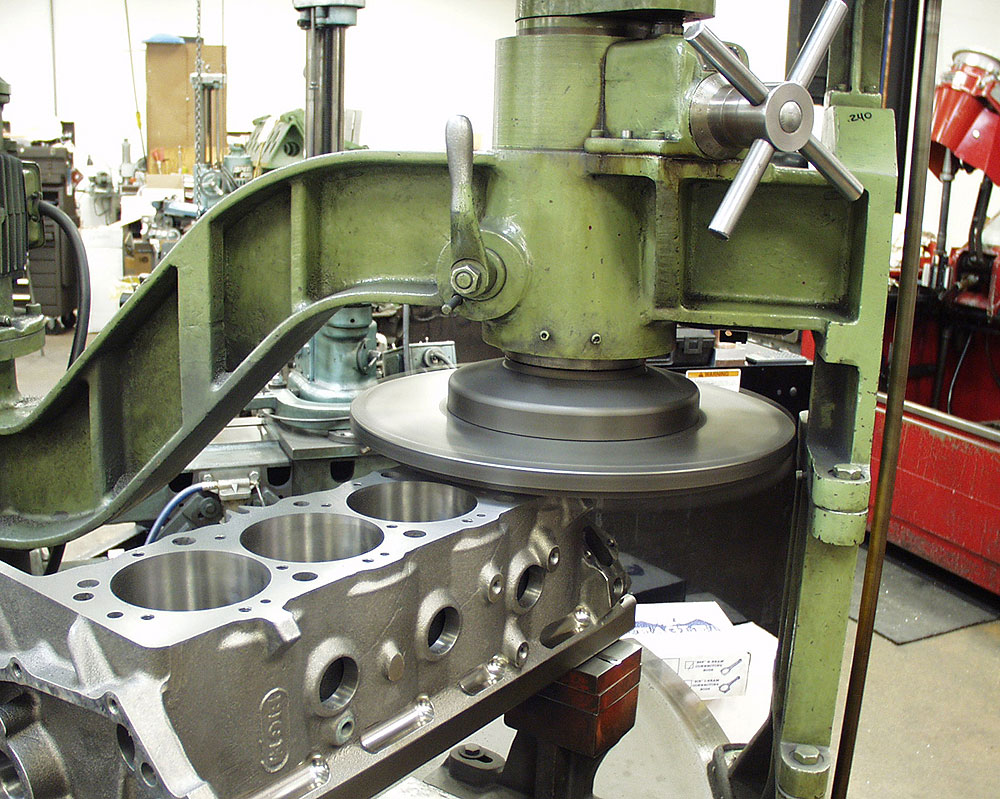

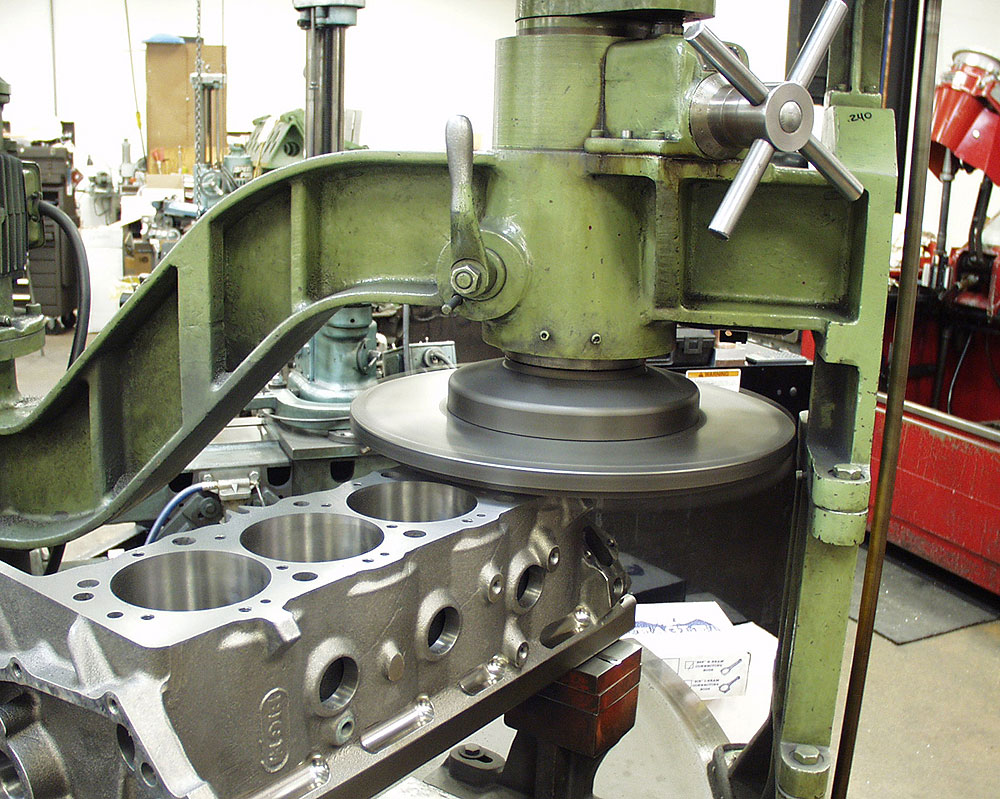

maxracesoftware wrote:i have a Storm Vulcan Block Master 85-BE

Electric drive, infinte variable speed, cuts Forwards / Backwards

4-Leg , replaceable cutter insets with 4 cutting edges per side , 8 Total

cutting edges on each insert

never had a problem with the 85 BE , mills Blocks or Heads , or

anything you can mount up

the variable speed electric drive can go from a Mirror Finish to Rough Finish,..you can set the speed to a crawl , taking 10 minutes to mill a Head

if you'd like or any other speed for a rougher/faster cut

the only real disadvantage is the 85BE mills in an arc across the Head

so in order to mill Intake sides of Heads with Lips, need to setup in Vertical Mill

it took me a Day and a half to adjust all the Bridges under the Machine,

i got the surface to .00025" accuracy anywhere on the bottom table

if you want to mill 1/2 Thousandths off a Head ...you can

http://www.maxracesoftware.com/Anglemill_Supr_2.jpg

this version has the largest diameter cutter wheel ever offered in the 85

17 or 18 adjustable cutters

very heavy duty rock solid Machine

the Machine mills "Dry" ..no coolant mess or cleanup

you can walk right up to the Machine and very easily, quickly mount

a Cyl Head, everythings right in front of you, easy access

the Dial Feed is really a large accurate "Micrometer" reads in thousandths and is on the money full travel

i've added a 2 inch depth Dial Indicator just to verify the Dial Feed

(see Pic..the Indicator above the Feed Handle, not the one on the Head/Wheel)

easy Leveling ..see Pic..the 1" Dial Indicator on the Wheel/Head

there were a few later versions that they moved the Motor ontop of the

Cutter wheel for direct drive, and reduced the rigidity of the swing arm , which was straighter and not as curved, but a few i've seen would have chatter marks .

also some versions SV reduce the overal height from Cutter Wheel to table by a few inches

some versions have smaller diameter wheel

some versions different Head holding fixture with different height

then there are the Head only versions (can't deck a Block, or most blocks)

SV-85BE could be vastly improved by converting to CBN inserts

Are these pictures still available? The link doesn't work anymore.

-

maxracesoftware

- Vendor

- Posts: 3656

- Joined: Sat Feb 14, 2004 4:04 pm

- Location: Abbeville, LA

- Contact:

Re: storm vulcan #85 surfacer

i need to find and re-upload those Pics again

in meantime,

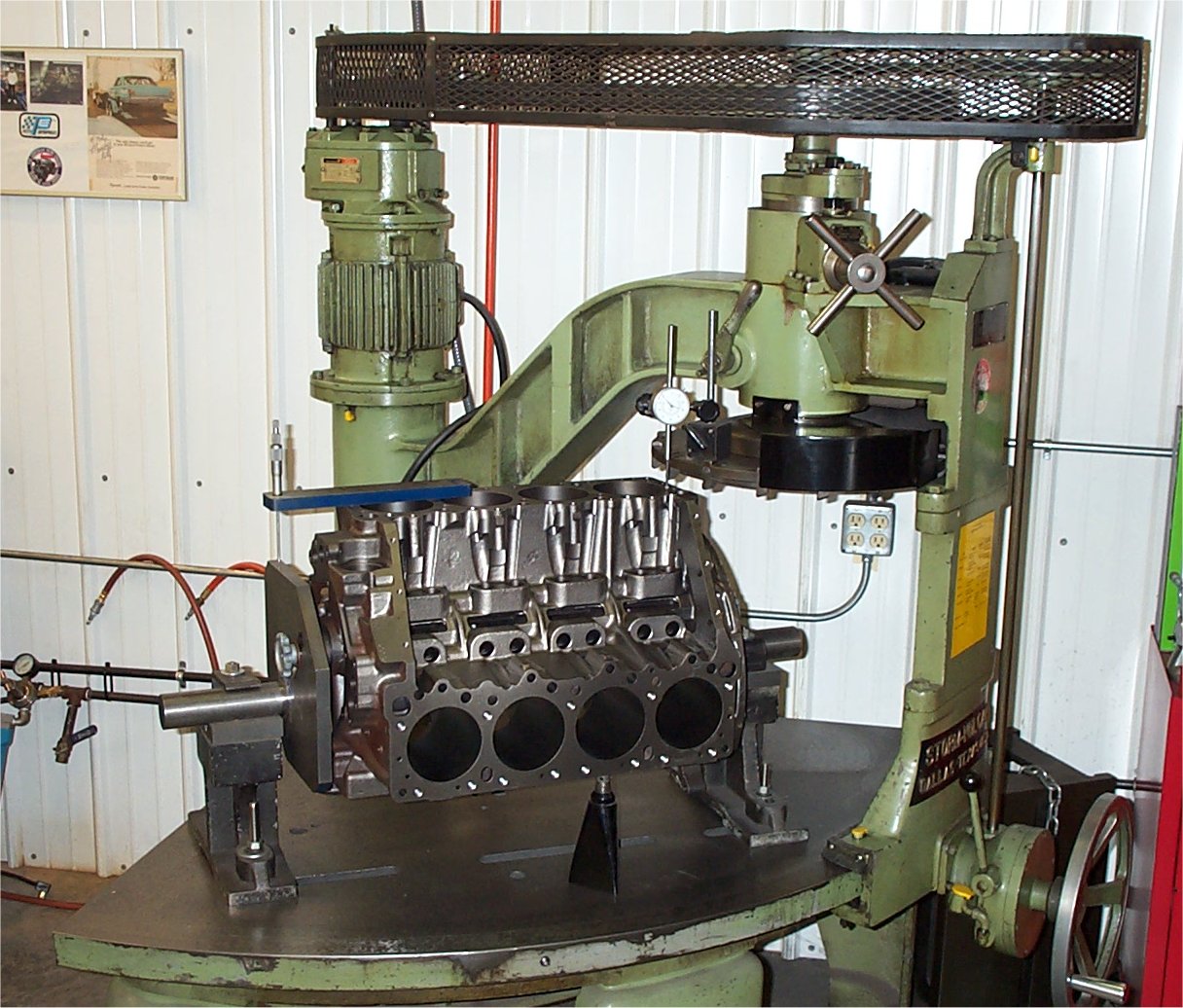

here's a pic of Reher - Morrison's SV85

its an older version than mine with front vertical shaft drive ( non-electric )

but the Wheel diameter looks the same as mine

in meantime,

here's a pic of Reher - Morrison's SV85

its an older version than mine with front vertical shaft drive ( non-electric )

but the Wheel diameter looks the same as mine

-

maxracesoftware

- Vendor

- Posts: 3656

- Joined: Sat Feb 14, 2004 4:04 pm

- Location: Abbeville, LA

- Contact:

-

maxracesoftware

- Vendor

- Posts: 3656

- Joined: Sat Feb 14, 2004 4:04 pm

- Location: Abbeville, LA

- Contact:

-

maxracesoftware

- Vendor

- Posts: 3656

- Joined: Sat Feb 14, 2004 4:04 pm

- Location: Abbeville, LA

- Contact:

-

maxracesoftware

- Vendor

- Posts: 3656

- Joined: Sat Feb 14, 2004 4:04 pm

- Location: Abbeville, LA

- Contact:

Re: storm vulcan #85 surfacer

maxracesoftware wrote:another pic from the internet

I ran one identical to that one everyday for well over 10 years. Milled heads and blocks and love that machine. I have seen many other styles and designs and to me the 85B is the best......

I CC'ed Stock and SS legal heads on it and did intake manifolds......We had a rollover table on a Bridgeport to do flanged heads like a BB chevy.....

I often had a block milling and was boring a another block with an FN boring bar on a boring stand right next to the 85B.....

I did have a block rollover on me once and that was not good.....small block ford......after that incident I tied every block down to the table and never made a cut more than .003 or .004 per pass on any block....

We were able to fix the cutter head after the flip incident but it took hours to get the cutters all right....

-

maxracesoftware

- Vendor

- Posts: 3656

- Joined: Sat Feb 14, 2004 4:04 pm

- Location: Abbeville, LA

- Contact:

Re: storm vulcan #85 surfacer

I ran one identical to that one everyday for well over 10 years. Milled heads and blocks and love that machine. I have seen many other styles and designs and to me the 85B is the best......

I CC'ed Stock and SS legal heads on it and did intake manifolds......We had a rollover table on a Bridgeport to do flanged heads like a BB chevy.....

I often had a block milling and was boring a another block with an FN boring bar on a boring stand right next to the 85B.....

I did have a block rollover on me once and that was not good.....small block ford......after that incident I tied every block down to the table and never made a cut more than .003 or .004 per pass on any block....

We were able to fix the cutter head after the flip incident but it took hours to get the cutters all right....

Do not ever use the Block hold method shown in Storm Vulcan's manualI did have a block rollover on me once and that was not good.....small block ford......after that incident I tied every block down to the table and never made a cut more than .003 or .004 per pass on any block....

because it will result in same exact incident you described !

i drill/tapped my SV85BE table for Eye Bolts on each side of block

to attach turnbuckles to table and block....block is super ridgid now

can easily mill .025-.035" off per pass if you ever wanted to ?

same way with Heads , i do not use SV's method 100%

Re: storm vulcan #85 surfacer

WE bought ours new in 1973,deadly accurate and durable ,added table speed control several years ago,Only repairs have been to sharpen cutters,got a guy here in Jersey that sharpens the cutters still on the wheel,has a good compromise cutter grind that will work on MLS.Bill C.

Ceralli Competition Engines & Checkered Flag Machine

Racing engines , CNC head porting and induction development

http://www.checkeredflagmachine.net/

Racing engines , CNC head porting and induction development

http://www.checkeredflagmachine.net/

Re: storm vulcan #85 surfacer

Shop I work out of has a Storm Vulcan RT-7Y with a CBN cutter retro-fit if you want a machine that can do it all and isn't a toy, look for a RT-7Y

It's the bigger brother of the already mentioned RT-17Y

It's the bigger brother of the already mentioned RT-17Y

-

Keith Morganstein

- Guru

- Posts: 5566

- Joined: Sun Feb 19, 2006 10:19 am

- Location: MA

Re: storm vulcan #85 surfacer

What to look for? Excessive wear on the perimeter of the table (the "way") where the arm support rides. Poorly maintained machines can easily have .015" wear there. There can also be considerable wear in the column that the arm pivots on. Not sure I've used the correct nomenclature, but I'm sure everyone will know what I'm describing.

Automotive Machining, cylinder head rebuilding, engine building. Can't seem to quit

- Dave Koehler

- Vendor

- Posts: 7207

- Joined: Mon Oct 04, 2004 11:19 pm

- Location: Urbana, IL USA

- Contact:

Re: storm vulcan #85 surfacer

No wear would be nice on that machine but if you need dead nuts alignment, dial indicating off the cutter head to the surface being cut will negate the wear affect. You do have to check both ends. If .001 - .002 is close enough, just touching down with the running cutter head at both ends to zero in will do the same thing.

Dave Koehler - Koehler Injection

Enderle Fuel Injection - Nitrous Charger - Balancing - Nitrous Master software

http://www.koehlerinjection.com

"Never let a race car know that you are in a hurry."

Enderle Fuel Injection - Nitrous Charger - Balancing - Nitrous Master software

http://www.koehlerinjection.com

"Never let a race car know that you are in a hurry."

Re: storm vulcan #85 surfacer

I love these machine I used a van norman 570 for years they were ok for reg work hated the fact you could not dial indicate anything in. But the storm 85 is awesome!