Page 1 of 5

Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 10:26 am

by BradH

Is there any public-domain research or testing available on possible benefits of tapered quench pads for NA applications?

This would be where the quench area has a small divergent angle from the cylinder-side to the plug-side of the pad (a "mini wedge" rather than parallel surfaces between the piston top and the cylinder head). I presume it's similar to what I hear as "softening" the chamber for power-adder applications.

Thanks - Brad

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 11:08 am

by Mikej26

I don’t have any info, but I’ve been wonder this same thing and am looking forward to what others have to say.

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 11:27 am

by n2xlr8n

BradH wrote: ↑Mon Apr 15, 2019 10:26 am

Is there any public-domain research or testing available on possible benefits of tapered quench pads for NA applications?

Thanks - Brad

I saw an attachment or a link in the last 3 days posted here regarding this; it was a paper on the design considerations for a Toyota 4 cylinder.

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 11:37 am

by GARY C

I have been asking that for about 10 years now with no luck, in a recent discussion on FaceBook with power adder guys running different versions of soft chambers it seems they never gave it a thought as to the possible benefit of directing the quench on a na engine.

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 12:56 pm

by BOOT

Flame travel

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 1:22 pm

by Powertrip

The Toyota paper discussed a directed squish, not a tapered quench if I'm reading that paper correctly. There is a lot of anecdotal evidence in the two stroke and Harley bike world, but nothing as far as track or dyno proof. It is something I would like to investigate one day.

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 1:46 pm

by Truckedup

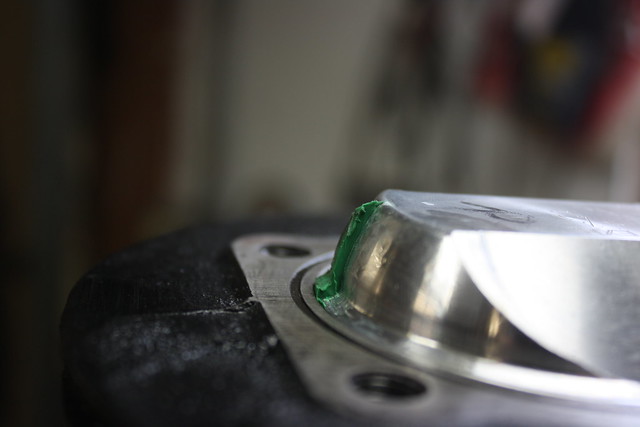

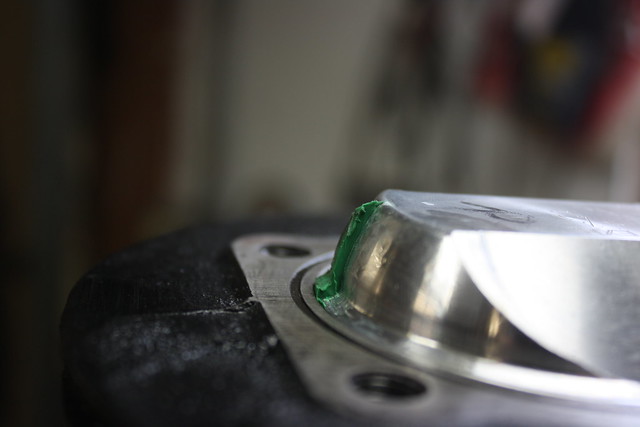

Maybe this is directed quench? This is on my hemi head vintage race bike...The quench you see is about .032-035......Does it work? I don't know but the engine , more moderately tuned and running lower rpm than the others, put the competition on the trailer for a few years in my land speed racing class...

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 2:54 pm

by learner1

As of yet i don't believe in tapered or angled cylinder head quench pads, however, my opinion is subject to change. I feel quench is very important and a tapered pad would reduce it and i wouldn't reduce the quench with a taper or angle in favor of directing it. I do believe in directing the mixture by shaping the piston to create quench and i believe in un-even quench pads.

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 6:45 pm

by Newold1

Do a search here on Speedtalk on both "quench" and "squish". Quote a bit of good input and findings.

Also go to Larry Widmers work at

www.theoldone.com

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 6:48 pm

by Newold1

Do a search here on Speedtalk on both "quench" and "squish". Quote a bit of good input and findings.

Also go to Larry Widmers work at

www.theoldone.com

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 7:20 pm

by digger

Tapered squish is surfaces that are not parallel? Some of what is being talked about seems to be "angled" squish bands

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 7:23 pm

by GARY C

Is a quench pad even needed or was it just the best place to fill in the piston to achieve the needed compression goals?

I think people trying to push the limits of crappy fuel led to the belief that all engines need a tight quench area but many high compression naturally aspirated race engines have been done with no quench pad what so ever as well as OEM engine with compression to fit the fuel at the pump, the big difference is that they run the proper fuel for the engine.

Here is an example of the type of piston.

Another

Re: Benefits of tapered quench for NA applications?

Posted: Mon Apr 15, 2019 10:06 pm

by pcnsd

There is a lot of conjecture regarding definitions and with regards to what others may have written I suppose it remains unclear at least to me. Regarding specifically the linked PDF. They are using squish to describe a parallel and angled piston to chamber shape and describing what sounds a lot like flame masking.

TAPER SQUISH COMBUSTION CHAMBER – The

squish area formed by the piston top and cylinder head

bottom surface has been tapered by being inclined along

the cylinder head combustion chamber wall (Fig. 10) .

This taper squish shape reduces the masking portion

around the intake valve when it is open, increasing intake

air volume (Fig. 11). Moreover, in the early stage of combustion,

this taper squish helps combustion pressure to

increase gradually and, at the latter part of combustion,

increases the burning velocity (Fig. 12), thereby en-hancing

anti-knock quality. It is inferred that the increase of

flow velocity to the squish area promotes the flame propagation

to the end of the squish area upon piston descent

(Fig. 13). Fig. 14 shows the benefits of the improved performance

in the prototype stage.

Really is worth reading and reviewing the various figures and will answer many of the questions posed here.

https://www.spyderchat.com/1zzfe.pdf

Re: Benefits of tapered quench for NA applications?

Posted: Tue Apr 16, 2019 7:51 am

by Dave Koehler

SBC 327, 462 casting. Tapered area over the spark plug area.

Is this an example of the tapered quench thinking from way back?

Re: Benefits of tapered quench for NA applications?

Posted: Tue Apr 16, 2019 8:54 am

by Truckedup

More of my vintage bike junk but i think it applicable....notice the 'sloped" thin squish band around the piston circumference that matches an area on the head...I milled the cylinder to get a .032 squish....These hemi head lumps are detonation prone on 93 octane with 9-1 compression because there was no effective squish from the factory....My bike engine runs detonation free on lower octane with a measured 9.15 compression and similar cam timing..I would have to say it works in my situation...

It seems from photos that newer stock sportbikes making far more N/A HP per displacement than any factory produced car ,have a narrow squish band around the combustion chamber....