Intake is a Weiand Action Plus dual plane.

Engine is a 461 ci BBC, 280H cam, stock (afaik) 820 iron cylinder heads with 2.06/1.72 valves.

Engine made 370 rwhp @ 5100 on a chassis dyno.

The goal is to let it breathe a bit better on the top end so it doesn't fall off so quickly. Since I road race my car, there are times where I hold gear and run it upwards of 6000 rpm.

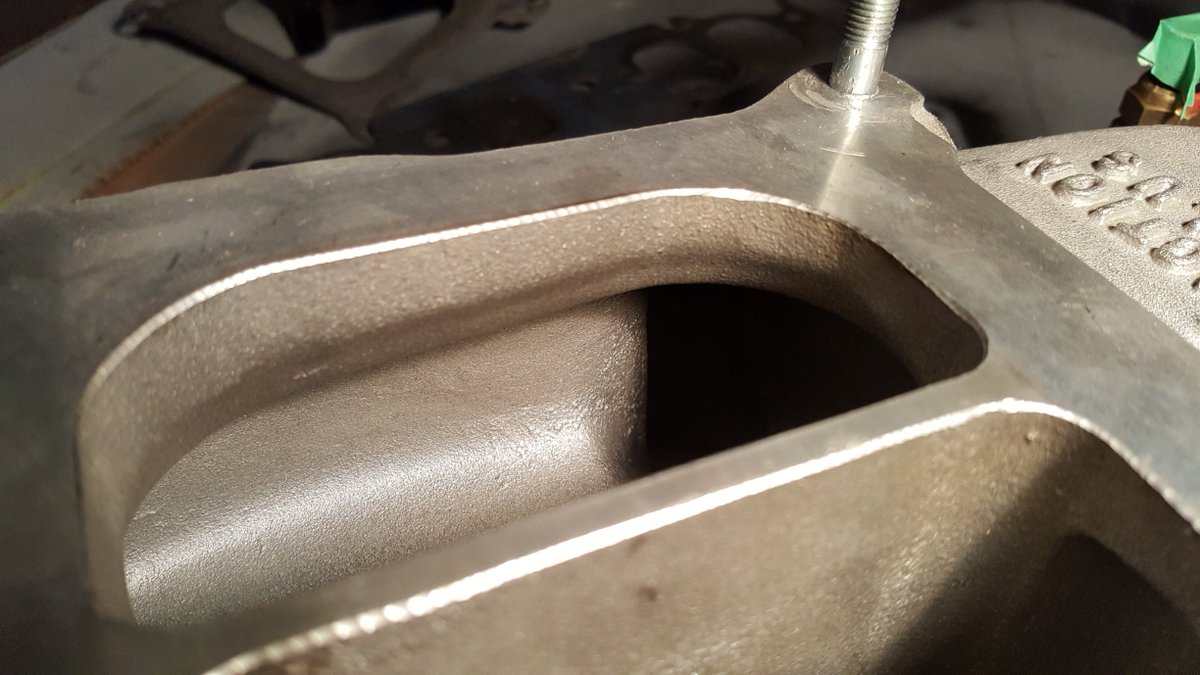

In stock as cast form:

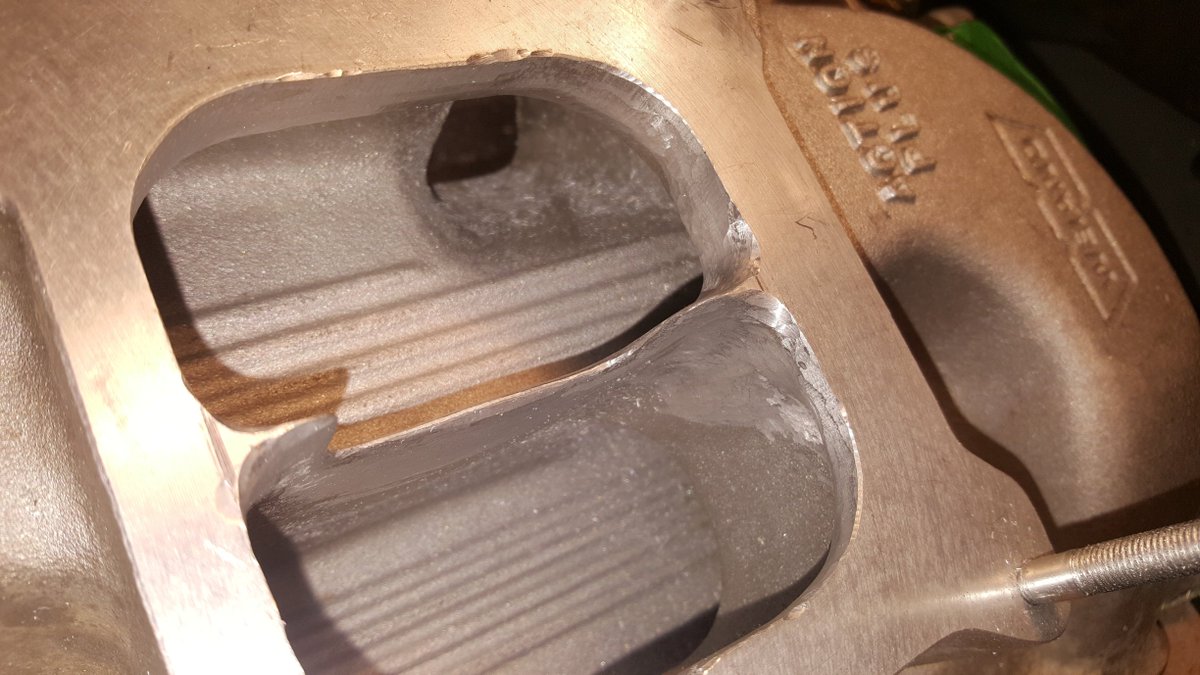

I already did some plenum mods. Divider cut down, and some blending.

My main question is in regards to the floor of the ports. When I lay the gaskets on my heads, the gasket/ports match pretty well. But as you can see the intake manifold ports don't match the gasket very well at all. I was thinking of reshaping the exit of the port to more closely match the entry of the cylinder head, which would mean removing material from the floor, and then blending about 2" into the port. I do not want to do any porting deep into the port, or reshaping the radius as there would be too much of a risk to completely bugger up the port to port distribution. Should I do a bit of "gasket matching" or just leave it?

Thanks