small bore hemi minimum quench

Moderator: Team

small bore hemi minimum quench

Not a Mopar Hemi but a vintage Triumph motorcycle....I run about .037 quench in my land speed race Triumphs with no problems.These engine have a deep hemi chamber and are detonation prone on pump gas.This is a street bike...3 inch bore, 3.23 stroke, 6 inch forged aluminum rods, pistons clearance is .0045, small rounded dome...The quench is a narrow 3/8 band around the piston..Maximum RPM might be 7000....Right now it's .032 on an engine mock up...I would like to run it this tight... but....too little?

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

Re: small bore hemi minimum quench

How much quench area % is there? The lesser area, the closer I think you would want to run to contact.

There seem to be a number of guys running at/under 0.030" with typical 350 SBC parts and steel rods. The factory spec for my 1970 495" BBC is 0.005" out of the hole with a 0.041" gasket. 4.0" stroke, 7,200 RPM max and anvil-like TRW pistons. Aluminum rods would be a significant factor though...

There seem to be a number of guys running at/under 0.030" with typical 350 SBC parts and steel rods. The factory spec for my 1970 495" BBC is 0.005" out of the hole with a 0.041" gasket. 4.0" stroke, 7,200 RPM max and anvil-like TRW pistons. Aluminum rods would be a significant factor though...

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

Re: small bore hemi minimum quench

Well, a 3/8" band around the piston circumference ,so not much....The original rods are forged from what what the Brits call Hiduminium RR56 and I have no idea how that compares with modern aluminum rods made from forged billet...My one racer has R&R alloy rods with .037 quench, the other has steel rods...I do know that tight quench does these engines good...MadBill wrote: ↑Wed Nov 07, 2018 2:58 pm How much quench area % is there? The lesser area, the closer I think you would want to run to contact.

There seem to be a number of guys running at/under 0.030" with typical 350 SBC parts and steel rods. The factory spec for my 1970 495" BBC is 0.005" out of the hole with a 0.041" gasket. 4.0" stroke, 7,200 RPM max and anvil-like TRW pistons. Aluminum rods would be a significant factor though...

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

Re: small bore hemi minimum quench

With my 2004 ZX10R (I know, very different engine) the official race setup manual (available back in the day from Kawasaki) recommended 0.65mm squish clearance and that is on an engine with 76mm bore (close to yours) and 55mm stroke (about two thirds of yours). Your proposal is 0.8mm squish clearance, which I would consider to be quite a bit. I've never messed with aluminium rods, though. You've got more piston to cylinder clearance than I do but I betcha your pistons have much longer skirts than mine. Good chance my engine has more opportunity for piston rocking than yours.

I would ruff guess rod stretch to be around 0.2mm at engine redline, and it will be doing that on the version of TDC between exhaust and intake stroke, and at TDC on the compression stroke under shut throttle conditions.

I would ruff guess rod stretch to be around 0.2mm at engine redline, and it will be doing that on the version of TDC between exhaust and intake stroke, and at TDC on the compression stroke under shut throttle conditions.

Re: small bore hemi minimum quench

Pardon the swear word but later in the Harley development they got away from the full hemi like a pan and shovel and went to some variants of the hemi with bathtub chambers which solve the issue you have. The triumph would be tricky to incorporate this before shrouded valves becomes the next issue. Plus the valves and their chamber are deep which complicates things. On the plus side those heads have steep angles and with the hemi design they would unshroud somewhat quickly if the quench pads were designed right, think kidney shaped with flat side walls at 45deg angle out of the seat.

Re: small bore hemi minimum quench

This Triumph 750cc engine is a 1979 model year and like all "Meriden"Triumph engines it is is pure 1930's motorcycle technology...two large valves with a 90 degree angle set in a classic hemi chamber..The chamber is 60cc's..The stock pistons are a rounded dome with a the narrow band that matches the perimeter band of the combustion chamber. Some have tried welding in quench areas like on lather Harleys but it just inhibits breathing... Raising intake port floors and using a good piston dome design, these engines can make near 100 HP per liter, the limit of most 2 valve engines...There are 4 valve per cylinder heads available for guys with big bucks...Guys like me can get about 1.7 hp per cubic inch stock crank breakage become an issue..

And a thanks to the guys here for tips that make Chevys go fast, lol.I held several land speed records in the modified production 650 pushrod gas class for nearly 5 years.

I just measured the quench again and it's .026 with a .045 headgasket and no cyinder base gasket...I have a .008 copper cylinder base gasket to jack it up to .034 quench..Next step is .018 composite base gasket and I can use a .040 head gasket for about .039 quench..,,

I think .039 quench is a bit light for this engine build....I guess the only way to know is to do it, Yes?

And a thanks to the guys here for tips that make Chevys go fast, lol.I held several land speed records in the modified production 650 pushrod gas class for nearly 5 years.

I just measured the quench again and it's .026 with a .045 headgasket and no cyinder base gasket...I have a .008 copper cylinder base gasket to jack it up to .034 quench..Next step is .018 composite base gasket and I can use a .040 head gasket for about .039 quench..,,

I think .039 quench is a bit light for this engine build....I guess the only way to know is to do it, Yes?

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

Re: small bore hemi minimum quench

I'd do it. I had a 650 back in the 70's that I tightened up the clearances on that made it run better. My buddy had an 850 Norton Commando that we did something similar. I don't remember the specs on that motor but they were given to us by the Norton dealer. If I remember right they came from a racer. Machining specs, carb, cam & exhaust. That bike ran great power wise but it wasn't a good street build. It was fast though.

Re: small bore hemi minimum quench

You are in a bit if a trap with this engine in a couple of ways, Truckedup has already covered some of the following but to add to [mind you these engines were cutting edge in their inception days] trying to get comp into one of these and squish makes for one crowded combustion chamber where every comp gain results in more combustion shrouding and every additional cam event results in deeper pockets and valve cutout to back of top ring groove weakness so the dome climbs higher , [as you are a LSR guy none of this is new] .

Some time back i did a methanol Sporty engine ,when i wet out the engine after the heads were done ,the comp was nothing like what is was claimed to be, so molds were done and sent to CP who made pistons that had a bit of room to move in all directions ,we had scope to change the comp by a point and a half as the sides of the piston are almost vertical the squish was kept at .040" in terms of radial and climb into dome clearance when assembled at max comp we found we could not have everything without getting into multiple piston shapes . Is a custom piston possible? or do you already have what you have to work with?

The original stock rods are now many years old with story's about themselves that are lost to time , if you can squeeze the budget, a set of steel rods will give a lot of tolerance and peace of mind to what the engine will see in use ,.032" with a steel rod at 7000 would be quite happy.

As you have been at this game for a while there is probably not much you have not already seen, experienced, and possibly dealt with a customer with a budget that does not match the performance expected ,but there are a few insurance policies if factored into the original build discussion will not rear their heads later in the build,valve train and rods are high on the list.

The photo of the original piston molds show the plug in the original location ,this was later shifted as high in the chamber possible and changed to 10mm.

Cheers.

Some time back i did a methanol Sporty engine ,when i wet out the engine after the heads were done ,the comp was nothing like what is was claimed to be, so molds were done and sent to CP who made pistons that had a bit of room to move in all directions ,we had scope to change the comp by a point and a half as the sides of the piston are almost vertical the squish was kept at .040" in terms of radial and climb into dome clearance when assembled at max comp we found we could not have everything without getting into multiple piston shapes . Is a custom piston possible? or do you already have what you have to work with?

The original stock rods are now many years old with story's about themselves that are lost to time , if you can squeeze the budget, a set of steel rods will give a lot of tolerance and peace of mind to what the engine will see in use ,.032" with a steel rod at 7000 would be quite happy.

As you have been at this game for a while there is probably not much you have not already seen, experienced, and possibly dealt with a customer with a budget that does not match the performance expected ,but there are a few insurance policies if factored into the original build discussion will not rear their heads later in the build,valve train and rods are high on the list.

The photo of the original piston molds show the plug in the original location ,this was later shifted as high in the chamber possible and changed to 10mm.

Cheers.

You do not have the required permissions to view the files attached to this post.

Re: small bore hemi minimum quench

My competitors, Triumph and BSA, run at least one full point or more compression and hotter cams than me...They need to run their engines at a higher rpm...I use a tight quench low dome 10.5 piston and never run the engine over 7000 rpm ...For Triumphs, it's my opinion ,high dome 11 and 12 to one compression pistons may affect how flow gets past the valve at lower lifts and the big dome may take up combustion heat better off pushing on the piston...

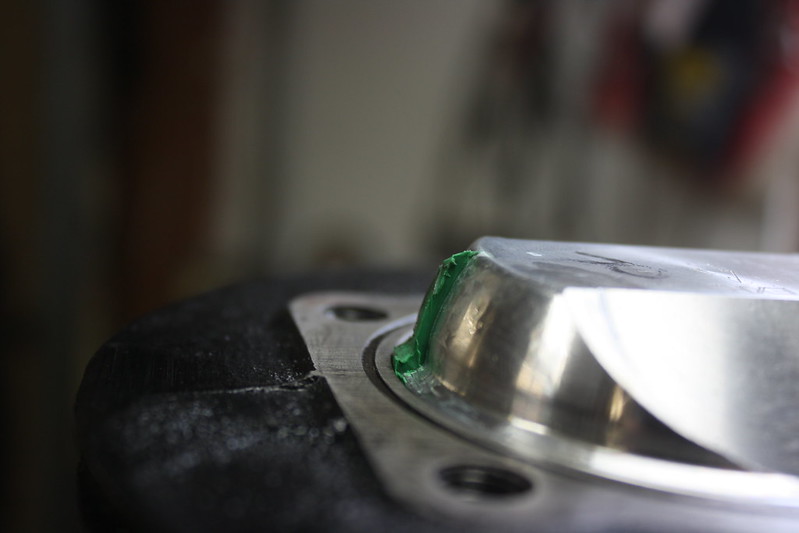

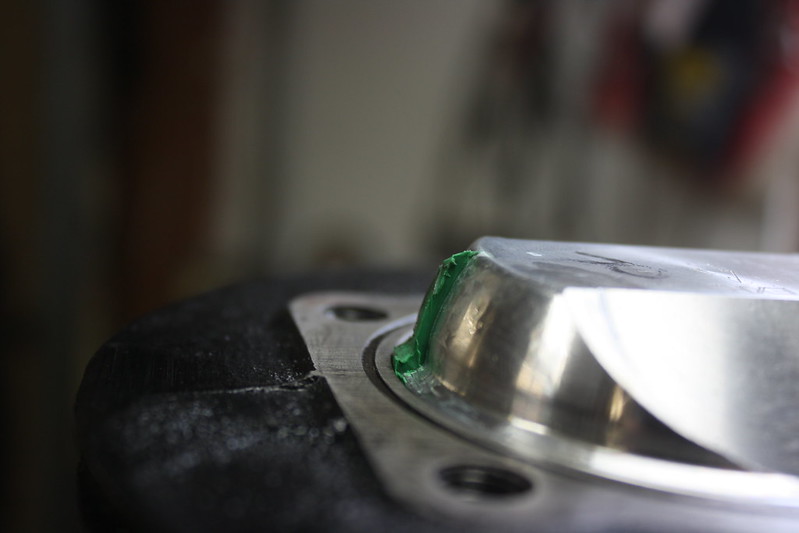

This is .037-039 quench on the forged 10.5 pistons in my two race bikes

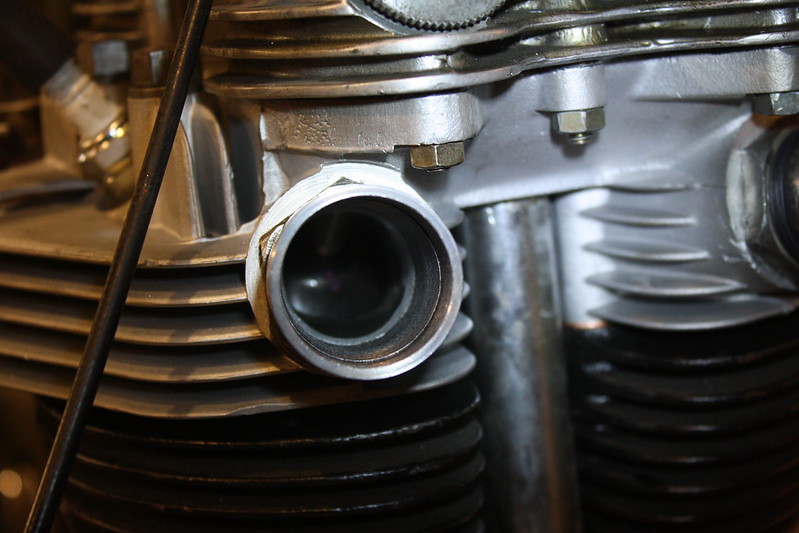

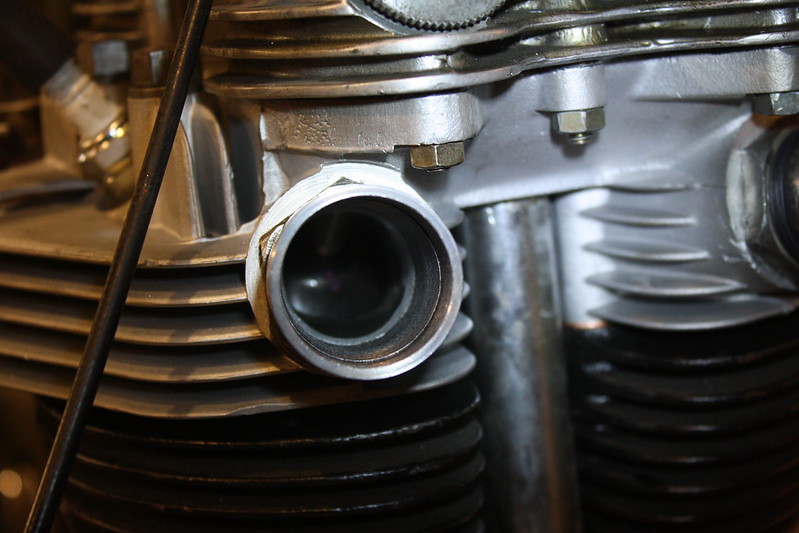

Stock Intake ports are large but shaped wrong with a sharp short side turn ... You can see the dark epoxy used to raise the port floor, in real life it's more than what the photo shows... More power requires relocating spring seat to raise the ports more...And expensive billet cranks..

The bike in the thread here is a street bike, no head work.. I have other street bikes so it probably won't be ridden more than 800 miles a year.Just a toy for rural rural roads in my area.

This is .037-039 quench on the forged 10.5 pistons in my two race bikes

Stock Intake ports are large but shaped wrong with a sharp short side turn ... You can see the dark epoxy used to raise the port floor, in real life it's more than what the photo shows... More power requires relocating spring seat to raise the ports more...And expensive billet cranks..

The bike in the thread here is a street bike, no head work.. I have other street bikes so it probably won't be ridden more than 800 miles a year.Just a toy for rural rural roads in my area.

Last edited by Truckedup on Wed Nov 07, 2018 7:06 pm, edited 2 times in total.

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

Re: small bore hemi minimum quench

Opps. double post

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

Re: small bore hemi minimum quench

That steep flank looks like it could act as an angled squish band, as used for example in many recent Toyotas. Perhaps with a more radiused transition from the flat periphery to aid squish flow.Truckedup wrote: ↑Wed Nov 07, 2018 6:50 pm My competitors, Triumph and BSA, run at least one full point or more compression and hotter cams than me...They need to run their engines at a higher rpm...I use a tight quench low dome 10.5 piston and never run the engine over 7000 rpm ...For Triumphs, it's my opinion ,high dome 11 and 12 to one compression pistons may affect how flow gets past the valve at lower lifts and the big dome may take up combustion heat better off pushing on the piston...

This is .037-039 quench on the forged 10.5 pistons in my two race bikes

Stock Intake ports are large but shaped wrong with a sharp short side turn ... You can see the dark epoxy used to raise the port floor, in real life it's more than what the photo shows... More power requires relocating spring seat to raise the ports more...And expensive billet cranks..

The bike in the thread here is a street bike, no head work.. I have other street bikes so it probably won't be ridden more than 800 miles a year.Just a toy for rural rural roads in my area.

Also, speaking of base gaskets, it would be quite elegant if you could split them in such a way as to permit their removal without tearing down the top end. Fit and test ever-thinner ones until a bore scope revealed light contact*, then go back up a few thous. *Could check after successively higher RPM tests: 5000, 6000, 6500, etc..

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

Re: small bore hemi minimum quench

One of the reasons for keeping clearances in the .030"-.040" clearance range is the piston has considerable side clearance with the cam grind , the side clearances can if the piston is moved side to side close up quick , i know when the engine is running the piston tracks pretty much in the middle of the bore but if something has a potential side play due to internal clearances these have to be factored into the final calculation.

Cheers.

Cheers.

-

grandsport51

- Pro

- Posts: 274

- Joined: Sun Jan 14, 2007 11:47 am

- Location:

Re: small bore hemi minimum quench

Trucked Up have you seen this old Manx

Norton Info?

Norton Info?

You do not have the required permissions to view the files attached to this post.

LIGHT 'EM UP

-

ProPower engines

- Guru

- Posts: 8706

- Joined: Sun Jan 21, 2007 1:16 pm

- Location: Victoria BC Canada

Re: small bore hemi minimum quench

What about fuel?? What are you allowed to run by the rules?? And have you considered alcohol fuels??

That will help the detonation issue and you may pick up more power then expected with the extra fuel volume needed it will act like you have more comp.

We run a 62% blend of E100 and reg. pump gas in a project engine.The consistency of E-100 fuel and reg pump gas allowed me to get much better power with a limited carb size by just adding more pump gas til the engine was happiest in the HP

department as well it picked up a ton more torque in the process.

That will help the detonation issue and you may pick up more power then expected with the extra fuel volume needed it will act like you have more comp.

We run a 62% blend of E100 and reg. pump gas in a project engine.The consistency of E-100 fuel and reg pump gas allowed me to get much better power with a limited carb size by just adding more pump gas til the engine was happiest in the HP

department as well it picked up a ton more torque in the process.

Real Race Cars Don't Have Doors