Rochester Ram Jet Fuel injection

Moderator: Team

Rochester Ram Jet Fuel injection

Does any one know the air meter air flow and how much horsepower it can support? How camshaft sensitive is it as far as duration and lobe separation ?Does the 63-65 units perform any better?

Re: Rochester Ram Jet Fuel injection

Because it is not as sensitive to overlap, the Rochester usually handles cams better than one or two 4-bbls.

Jack Vines

Studebaker-Packard V8 Limited

Obsolete Engineering

Studebaker-Packard V8 Limited

Obsolete Engineering

-

pamotorman

- Guru

- Posts: 2802

- Joined: Thu Mar 06, 2014 11:55 pm

- Location:

Re: Rochester Ram Jet Fuel injection

the speedo cable type drive for the pressure pump does not like more than 6500 engine RPMs. when we raced them we ran without the outer drive cable cover so it could be changed quickly out on the track. they tried moving the pump to the distributor to try and cure the problem.

You do not have the required permissions to view the files attached to this post.

-

pamotorman

- Guru

- Posts: 2802

- Joined: Thu Mar 06, 2014 11:55 pm

- Location:

Re: Rochester Ram Jet Fuel injection

this was corvette grand sport race car only engine and it idled about 1000 RPMs

Re: Rochester Ram Jet Fuel injection

Interesting topic...

Motorcycle land speed racing... wearing animal hides and clinging to vibrating oily machines propelled by fire

-

grandsport51

- Pro

- Posts: 274

- Joined: Sun Jan 14, 2007 11:47 am

- Location:

Re: Rochester Ram Jet Fuel injection

Zora and the boys at Rochester

Factory info from '62

http://chevy.oldcarmanualproject.com/sh ... 06m01.html

Jerry Bramlett interesting info also

https://jerrybramlett.net/tips.html

Interesting Video dual throttle valves

http://chevroletfuelinjection.com/dual-air-meter-units/

Cool Stuff

Dave B.

Factory info from '62

http://chevy.oldcarmanualproject.com/sh ... 06m01.html

Jerry Bramlett interesting info also

https://jerrybramlett.net/tips.html

Interesting Video dual throttle valves

http://chevroletfuelinjection.com/dual-air-meter-units/

Cool Stuff

Dave B.

LIGHT 'EM UP

-

kirkwoodken

- Guru

- Posts: 1541

- Joined: Thu Dec 06, 2007 11:35 pm

- Location:

Re: Rochester Ram Jet Fuel injection

Jerry Bramlett has a great accumulation of Rochester FI knowledge. I can only add little with my experience. Of my original Bill Thomas unit, I can say this:

The air meters have the choke blades removed and are bored straight through to clean out the metal left in the venturis so they could use a standard type choke plate found on many Rochchester carbs.

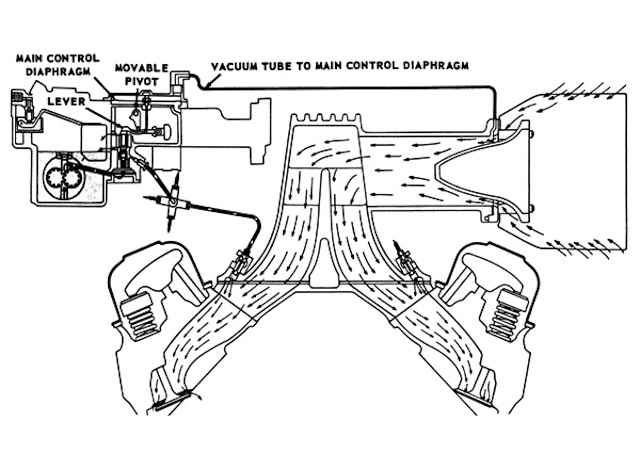

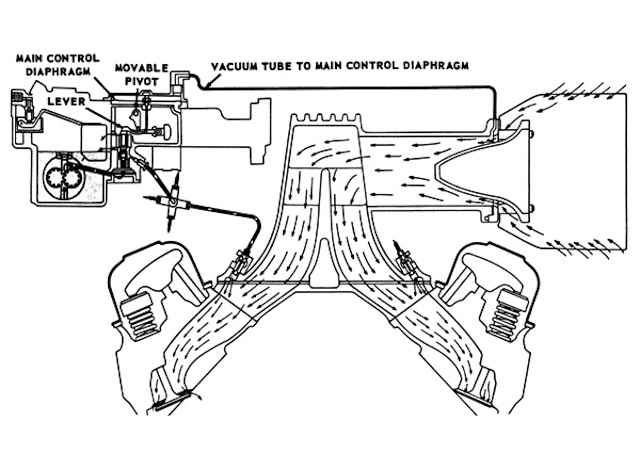

The tapered outside of the venturi inserts had the angles increased about 1 1/2 degrees to increase the vacuum signal. When you add a second air meter, the venturi signal drops to 1/4 of the signal of one meter or about 1/8th inch of water which is virtually nothing. Since the signal to the main control diaphragm is only getting 1/4th of the designed vacuum, the area that the spill plunger is trying to control must also be cut to 1/4 of the AREA of the standard spill plunger. Standard spill plunger is 9/32" diameter, so the hole in the spill valve is sleeved down to 9/64", allowing the valve to operate at its designed intent.

One of the successes of the Rochester fuel nozzles is they were designed to spray into atmospheric pressure, eliminating the pulsing of spraying into a high vacuum area. This adds to the street performance the FI was famed for and aided in atomization of fuel flow. On the stock units, filtered air from the air cleaner was fed through the nozzle blocks and flowed 1/3rd of the idle air and was metered air, not just air sucked from the outside. This was important for good street idling and low speed driving, and was not influenced by changing under-hood air pressures.

In a recent post about the Rochester, I mentioned the design was to have the Main Control Diaphragm acted upon by signals from both sides; The top side acted upon venturi vacuum/pressure from the above side and the impact pressure from a tube in the air entry of the air cleaner base on the bottom side, much as a pitot tube operates.

My cam is a Harold Brookshire's favorite grind: 255/263 on 109 LDA with .600" lift. This gives 1200 RPM idle speed and 10" manifold vacuum at idle. Engine is 10:1 406. It made 455 Ft.Lbs. torque on Bob Steigemeier's chassis, what ever that means. When I got to his shop to adjust rich and lean stops, the first thing Bob did was to call 4 of his friends to come and see a Rochester FI ! He had not seen one before and told his friends they would probably never see another. He was surprised at the fuel curve and how well it performed. Said he had heard they were "dogs" but mine worked pretty good.

Air flow through the FI doghouse was in the 230 range as tested by Bob, about 20 cfm less than the AFR 210"s. And remember the first Tunnel Ram was Rochester with a carb plate on top.

According to the pump sizing, it could possibly pump enough gas for 900 HP. If I win the lottery, I'll add two spray bars above the air meters.

I like to say the Rochester's complexity is clothed in simplicity. I believe they are a much better design than most realized. If the rich/lean screws are 1/6th of a turn off, power drops. One of my goals is to give PDQ Paul a ride while we are still kicking. (Sorry Paul, but it signs off pulling hard at about 6600 but that is what I wanted.)

The air meters have the choke blades removed and are bored straight through to clean out the metal left in the venturis so they could use a standard type choke plate found on many Rochchester carbs.

The tapered outside of the venturi inserts had the angles increased about 1 1/2 degrees to increase the vacuum signal. When you add a second air meter, the venturi signal drops to 1/4 of the signal of one meter or about 1/8th inch of water which is virtually nothing. Since the signal to the main control diaphragm is only getting 1/4th of the designed vacuum, the area that the spill plunger is trying to control must also be cut to 1/4 of the AREA of the standard spill plunger. Standard spill plunger is 9/32" diameter, so the hole in the spill valve is sleeved down to 9/64", allowing the valve to operate at its designed intent.

One of the successes of the Rochester fuel nozzles is they were designed to spray into atmospheric pressure, eliminating the pulsing of spraying into a high vacuum area. This adds to the street performance the FI was famed for and aided in atomization of fuel flow. On the stock units, filtered air from the air cleaner was fed through the nozzle blocks and flowed 1/3rd of the idle air and was metered air, not just air sucked from the outside. This was important for good street idling and low speed driving, and was not influenced by changing under-hood air pressures.

In a recent post about the Rochester, I mentioned the design was to have the Main Control Diaphragm acted upon by signals from both sides; The top side acted upon venturi vacuum/pressure from the above side and the impact pressure from a tube in the air entry of the air cleaner base on the bottom side, much as a pitot tube operates.

My cam is a Harold Brookshire's favorite grind: 255/263 on 109 LDA with .600" lift. This gives 1200 RPM idle speed and 10" manifold vacuum at idle. Engine is 10:1 406. It made 455 Ft.Lbs. torque on Bob Steigemeier's chassis, what ever that means. When I got to his shop to adjust rich and lean stops, the first thing Bob did was to call 4 of his friends to come and see a Rochester FI ! He had not seen one before and told his friends they would probably never see another. He was surprised at the fuel curve and how well it performed. Said he had heard they were "dogs" but mine worked pretty good.

Air flow through the FI doghouse was in the 230 range as tested by Bob, about 20 cfm less than the AFR 210"s. And remember the first Tunnel Ram was Rochester with a carb plate on top.

According to the pump sizing, it could possibly pump enough gas for 900 HP. If I win the lottery, I'll add two spray bars above the air meters.

I like to say the Rochester's complexity is clothed in simplicity. I believe they are a much better design than most realized. If the rich/lean screws are 1/6th of a turn off, power drops. One of my goals is to give PDQ Paul a ride while we are still kicking. (Sorry Paul, but it signs off pulling hard at about 6600 but that is what I wanted.)

"Life is too short to not run a solid roller cam."

"Anything is possible, if you don't know what you're talking about."

I am NOT an Expert, and DEFINITELY NOT a GURU.

Kirkwoodken

"Anything is possible, if you don't know what you're talking about."

I am NOT an Expert, and DEFINITELY NOT a GURU.

Kirkwoodken

Re: Rochester Ram Jet Fuel injection

A VERY long time ago I helped turbocharge a Rochester equipped 350. The engine was a stock 2bbl from a Chevelle. The owner had ditched the manifold and carb for an Edlebrock and a 650. With headers it made 290hp on a Stuska. The turbo conversion used RotoMaster manifolds and I don't know what turbo. The compressor was connected to the Rochester plenum with exhaust mandrel bends. I don't remember how the air meter was hooked to the compressor. The Rochester nozzle disks needed to be drilled out to get enough fuel flow. The nozzle block aspiration vents were left open to atmosphere. Don't remember what boost---maybe 7psi? On leaded pump Hi-test (loooong time ago)it made 390hp.