Zmechanic wrote: ↑Fri Oct 12, 2018 4:29 pm

PackardV8 wrote: ↑Fri Oct 12, 2018 3:57 pm

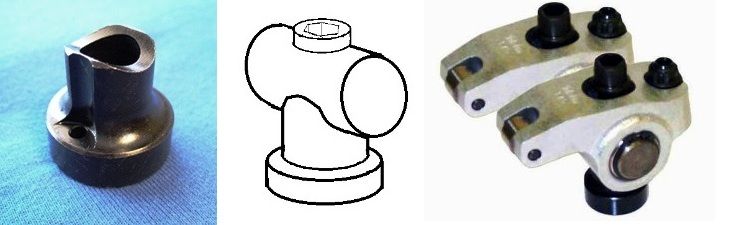

When starting down that road, why stop with the pedestal? Would anyone here choose the eight individual pedestals held down with 7/16" bolts over a true single continuous shaft system? Your thoughts on the +/- of each?

jack vines

In a perfect world, but that only works in a wedge head with inline valves.

The whole point is to get the pivot point of the rocker as rigid as possible, be it stand mount, pedestal mount, or otherwise.

Now as for what's necessary? Well, there are sprint motors out there now turning 7200rpm+ with 350lb open loads on 3/8" studs with 1.5:1 rockers. It's far from ideal, and done purposefully as one of the efforts to try to limit them. However there are lots of race engines turning far beyond that still using stud rockers and girdles.

If you can, bump up to 7/16" studs. If you think that's not enough, price it out with studs and girdles. You'll probably be within striking distance of a set of shaft rockers. Feature creep yourself until you can't stand to pay anymore, at least that's what I do. Haha.

If I have a choice when using stud mounted rockers I will always go with the 7/16" stud!

Todays manufacturing systems have afforded us the same cost for either a 3/8 stud rocker system or a 7/16" mounting system,

In checking some stud deflection between the 3.8 and 7/16 stud the 3/8 flexed an average of .025 to .035 compared to the larger stud that did not show but .003 flex.

3/8 stud rockers have been an issue since the 70's where a stud girdle was used to keep the studs from flexing and breaking but material and manufacturing techniques have improved 10 fold since then to where the studs and rockers are the same cost for 3/8 or 7/16 making the stud system cheaper then a shaft system.

Yella Terra came up with a good idea but like all shaft mount rocker systems they are twice the money over a stud mounted rocker system and with the availability off set intake rockers most guys go that way rather then the shaft system because of cost. Chevys have the most R+D done for rockers but where a Mopar guy has has the same options there is more cost just because of the engine or head manufacture.

It seems there is alot of ford aftermarket heads use sm blk GM valve train stuff like valves and rockers to keep costs down anyway but the stock head stuff gets specific in alot of cases.

I have used alot of the Crower shaft rocker systems and a few Yella Terra systems but they are by far at least twice the cost of a good stud rocker system. I prefer the Crower shaft rockers over the Yella Terra on sm blks because they have a stronger full length mounting base where the YT and others use individual shafts and 2 bolts through pedestals.

JMO