Page 1 of 3

Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 1:02 pm

by PackardV8

In the July 2018 issue of Car Craft, Robert Poole and Mark Magda have a very detailed 3-page feature article on how to check P/V clearance with clay.

Just me, but I gave up on clay in 1964 after being given a lesson by Bobby Allison. I'd read how-to-clay in Hot Rod and wanted to show my expertise. He said, "Clay is for kindergartners. You use it and tell me how much P/V we've got. In fact, do it on three different cylinders. You'll measure three different guesses."

Of course, he was right and he showed me how to do it with checking springs, degree wheel, dial indicator and a clipboard.

So how many of us still use clay?

Or do you use a dial indicator? If so, is TDC valve drop OK or do you degree wheel from 20 BTDC to 20 ATDC?

Or do you trust a computer program to verify P/V clearance?

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 1:06 pm

by blykins

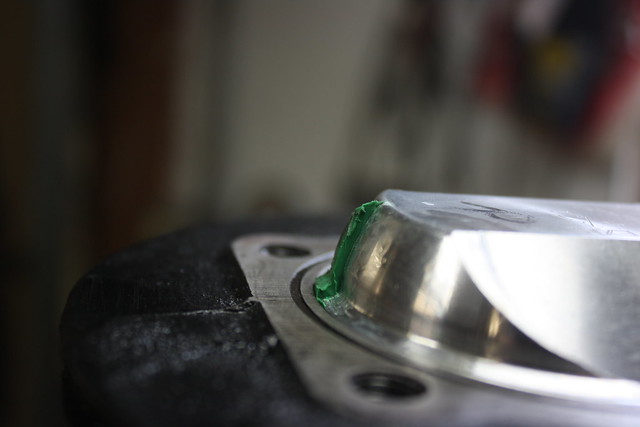

I use clay to check radial clearance. I use a degree wheel and dial indicator to check depth.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 1:12 pm

by statsystems

If you don't load the rocker with the actual spring you don't have accurate numbers. Clay is the only way to do it.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 1:45 pm

by maxracesoftware

you should always check Valve -to- Piston clearances with all your real Valve Springs

and entire assembled valvetrain fully-loaded , and with Dial Indicator/Magnetic Stand on the Retainer

don't use Clay .... if you use Clay .. just use the Clay to hold strips of Solder in place

its better to use 0.090" or 0.0120" diameter Resin or Acid-Core Solder to check than Clay

On a fully-assembled Engine :

you can use Solder thru the Spark Plug hole , across either the Intake or Exhaust Piston Valve Notches

turn over the Engine at 15deg BTDC-Overlap to 15 deg ATDC-Overlap

remove the Solder out the Plug hole , then measure with Dial Caliper.... if there's no contact at all , then you know it has 0.090" or 0.120" VPC

sometimes i need to do a quick check with Solder on the Dyno when i want to move a Cam around

and the Dyno Customer/Builder was not exactly sure what the VPC was ??

Dial Indicator/Magnetic Stand on the Retainer is still the most accurate Method to use .

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 1:55 pm

by statsystems

maxracesoftware wrote: ↑Thu May 03, 2018 1:45 pm

you should always check Valve -to- Piston clearances with all your real Valve Springs

and entire assembled valvetrain fully-loaded , and with Dial Indicator/Magnetic Stand on the Retainer

don't use Clay .... if you use Clay .. just use the Clay to hold the Solder in place

its better to use 0.090" or 0.0120" diameter Resin or Acid-Core Solder to check than Clay

On a fully-assembled Engine :

you can use Solder thru the Spark Plug hole , across either the Intake or Exhaust Piston Valve Notches

turn over the Engine at 15deg BTDC-Overlap to 15 deg ATDC-Overlap

remove the Solder out the Plug hole , then measure with Dial Caliper.... if there's no contact at all , then you know it has 0.090" or 0.120" VPC

sometimes i need to do a quick check with Solder on the Dyno when i want to move a Cam around

and the Dyno Customer/Builder was not exactly sure what the VPC was ??

I forgot about the solder. I did that a couple of times but I was within a few thou of the clay so I just do it with clay.

Solder does work.

On another note...I found this the hard way...different manufacturers use different methods to accomplish getting the rocker ratio correct under load.

For an example, I had a set of Crane gold rockers, some Harlan Sharp that were loaned to me and a set of Norris stainless steel rockers.

Every brand had a different ratio with light springs but they were all damn close with spring load on them. IIRC, the HS rockers were 1.71:1 with checker springs and 1.6 with load. The Crane and Norris were a bit less with the checker springs but they were all 1.6 loaded.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 2:01 pm

by maxracesoftware

using 0.090" to 0.120" Solder is a "firm measurement" with a Dial Caliper

whereas, trying to accurately measure depth ot thickness of the Clay might squish down a little from Dial-Cailper

it takes more skill or being careful , to measure the Clay than the Solder

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 2:07 pm

by blykins

Have you ever seen a case where you checked with clay and checking springs and the piston/valve clearance got *worse* with the actual springs/pushrods?

Most of the time, unless it's hairy close, or the pistons are sticking out of the holes, I don't even check with the head gasket or lash. If it's sufficient without those two items and with checking springs, then I'm gonna be good with lash, a head gasket, and pushrod deflection.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 2:13 pm

by Warp Speed

IMO, clay is good for checking radial, and can be used for checking overall if the proper indicators aren't handy (we've all been there before). After that, a dial indicator, degree wheel and checking springs works great during mock-up, as long as the valve timing is where it is supposes to be, and the value will only grow with the proper springs. If you are wanting to run as close as possible to gain compressiin for a heads up or severely rules limited deal, than all the above (clay for radial, checking springs ans degree wheel for mock-up, and real springs/lash and a degree wheel for final) should be used.

Solder....have heard that in years, but have done it.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 2:17 pm

by fdicrasto

blykins wrote: ↑Thu May 03, 2018 1:06 pm

I use clay to check radial clearance. I use a degree wheel and dial indicator to check depth.

Same here.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 2:22 pm

by maxracesoftware

just another hint : Solder ( or Clay ) , can also show you if your Piston Flycut Notch Angle matches up exactly with your Valve Head's angle

by measuring top and bottom Solder contact thickness across the Valves diameter

Solder is just quick checking you can do on the Dyno with unknowns or uncertainties with Customers

You cannot insert or remove Clay on an Engine on the Dyno

unfurling a length of Solder thru a Spark Plug hole is easy , quick

remove the Headers ... shine a light in the Exhaust Port ... look thru the Spark Plug hole

insert the Solder across the Valve Notch ... turnover the Engine by hand .. pull out the Solder ... measure with a Dial Caliper if theres contact

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 2:41 pm

by statsystems

maxracesoftware wrote: ↑Thu May 03, 2018 2:22 pm

just another hint : Solder ( or Clay ) , can also show you if your Piston Flycut Notch Angle matches up exactly with your Valve Head's angle

by measuring top and bottom Solder contact thickness across the Valves diameter

Solder is just quick checking you can do on the Dyno with unknowns or uncertainties with Customers

You cannot insert or remove Clay on an Engine on the Dyno

unfurling a length of Solder thru a Spark Plug hole is easy , quick

remove the Headers ... shine a light in the Exhaust Port ... look thru the Spark Plug hole

insert the Solder across the Valve Notch ... turnover the Engine by hand .. pull out the Solder ... measure with a Dial Caliper if theres contact

Yep, solder has its uses. It's funny I find most people run way more clearance than thay need.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 2:48 pm

by pcnsd

statsystems wrote: ↑Thu May 03, 2018 2:41 pm

maxracesoftware wrote: ↑Thu May 03, 2018 2:22 pm

just another hint : Solder ( or Clay ) , can also show you if your Piston Flycut Notch Angle matches up exactly with your Valve Head's angle

by measuring top and bottom Solder contact thickness across the Valves diameter

Solder is just quick checking you can do on the Dyno with unknowns or uncertainties with Customers

You cannot insert or remove Clay on an Engine on the Dyno

unfurling a length of Solder thru a Spark Plug hole is easy , quick

remove the Headers ... shine a light in the Exhaust Port ... look thru the Spark Plug hole

insert the Solder across the Valve Notch ... turnover the Engine by hand .. pull out the Solder ... measure with a Dial Caliper if theres contact

Yep, solder has its uses.

It's funny I find most people run way more clearance than thay need.

I think this is true because while it is less than optimal, it also saves a lot of work when you test and find your cam is better advanced or retarded from your initial placement.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 3:04 pm

by treyrags

statsystems wrote: ↑Thu May 03, 2018 2:41 pm

Yep, solder has its uses. It's funny I find most people run way more clearance than thay need.

We always used clay with solder pressed in. When we would tear our engines down I would be really concerned about having a few of the exhaust valve relieves having slight "kisses" on them from the valves touching. My dad would just laugh and say it's just right like that. Of course he was half kidding. If I remember right, we had .040 on intake and .060 on exhaust.

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 3:18 pm

by Walter R. Malik

blykins wrote: ↑Thu May 03, 2018 1:06 pm

I use clay to check radial clearance. I use a degree wheel and dial indicator to check depth.

YEP ...

Re: Is anyone still using clay to verify P/V clearance?

Posted: Thu May 03, 2018 5:04 pm

by Truckedup

Clay for measuring quench and piston valve pockets on my vintage hemi racing bike stuff ...Then soldier or checking springs with indicator for valve to piston