NewbVetteGuy wrote: ↑Thu Apr 26, 2018 6:46 pm

With an ornately designed piston crown shape and 3D printed pistons, could you help control swirl/ tumble and quench areas very closely?

-I think of the long threads on singh grooves and then compare it to what's possible with a 3D Printed Piston Crown and it's another universe.

Adam

The piston top isn’t the advantage. You can machine that currently with the current crop of CNC machines.

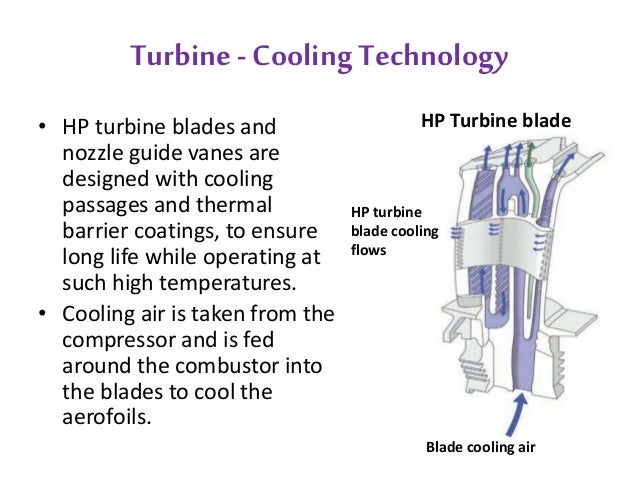

The printed and other casting techniques allows engineers to develop parts that are hollow or feature ornate cooling passages that will allow for lighter parts and better cooling. Both will allow for better wear as well as increased performance. The performance may not be as clear cut, but will likely allow designers to do other things that will add up to performance enhancements. Take a look at the Rolls Royce jet turbine blades for example.

For example, specially shaped passages and piston oil jets could allow for thinner rings and a more aggressive tune for a given service life. These enhancements are all well documented in high end racing series where builders have more liberty on design. Think FIA Le Mans, Moto GP, F1, etc. Will it matter for the ST typical 500hp 383ci Chevy? No, but those are boring and pretty archaic anyway.

Take a look here from a decade ago with Honda's F1 effort and what piston cooling got them:

www.f1-forecast.com/pdf/F1-Files/Honda/F1-SP2_08e.pdf . They spent a lot of time on oil the oil jet pattern.

As far as mixture motion goes, look no further than the current crop of sport bikes. They’re all in the 12.5-14.1 compression range from the factory on pump gas. Plenty of tumble action to get there, and on the small bore 600 bikes, they’re coming with 15,000rpm redlines from the factory. Combustion speed isn’t a problem, despite the relative large bore/stroke ratios. That’s all in the port design / angle and the combustion chamber to some degree.

An example of that, look at the previous Superbike Ducati V2 1299cc (79.2ci):

Bore: 116mm (4.566in)

Stroke: 60.8mm (2.393in)

Connecting Rod Length: 110.1mm (4.335in)

Compression Ratio: 12.6:1 (street trim).

Redline: 11,000rpm

1.90 bore/stroke ratio

1.81 rod/stroke ratio

That's a bigger bore than a GM LT-1 by almost half an inch, a full point higher compression for the same fuel, 5000rpm+ more, and without the aid of DI at lower engine speeds.

Not a Singh-groove in sight.

I wish we saw more threads like this here. We use to.