Curious.. would you still use and consider that same header size as optimal when combined with a tunnel ram like this?

Another Header issue.

Moderator: Team

-

groberts101

- Guru

- Posts: 1980

- Joined: Sat Mar 08, 2008 3:08 pm

- Location: Minneapolis

Re: Another Header issue.

Re: Another Header issue.

True, I think what they do give an idea of what will be the best choice for the guy that can't test and is looking for a product that gives a bolt on advantage at the same time it also shows the need for testing if you are looking for the best outcome and that even with a 400 ci with T.Ram bigger may not be better.cjperformance wrote: ↑Thu Mar 15, 2018 11:33 pmThey are always interesting tests to watch but it only really shows (and they say this in the vid) that the 1-3/4" set out of the 3 options available were the best option on that combo and tune.GARY C wrote: ↑Thu Mar 15, 2018 9:18 pm 400 ci SBC with T. Ram, header test, 1.5/8 vs 1.3/4.

https://www.youtube.com/watch?v=rTlHEOE ... HutSOu7srE

Please Note!

THE ABOVE POST IN NO WAY REFLECTS THE VIEWS OF SPEED TALK OR IT'S MEMBERS AND SHOULD BE VIEWED AS ENTERTAINMENT ONLY...Thanks, The Management!

THE ABOVE POST IN NO WAY REFLECTS THE VIEWS OF SPEED TALK OR IT'S MEMBERS AND SHOULD BE VIEWED AS ENTERTAINMENT ONLY...Thanks, The Management!

-

Casper393W

- Pro

- Posts: 422

- Joined: Wed Jul 06, 2016 7:18 am

- Location:

Re: Another Header issue.

You know that is a interesting question...groberts101 wrote: ↑Fri Mar 16, 2018 10:13 amCurious.. would you still use and consider that same header size as optimal when combined with a tunnel ram like this?

I have seen in some chassis Dyno tests I have done... Based on the camshaft that is installed, it has a huge effect on how much the smaller size headers and or exhaust system restricts power

For example....when I had my shop I did a series of Dyno tests with cams and complete exhaust systems on Modular powered mustangs... I found that if I ran a set of cams with say a 108 LSA the exhaust system played a bigger part in power production... Meaning I saw a greater gain from headers and catback systems vs a set of cams that was ground say on a 113 or 114 LSA. I'm sure that had to do with reversation during the overlap

. Calling Camking to comment on this???

After seeing the comments on this subject I do feel a bit better about it now....

-

hoffman900

- HotPass

- Posts: 3457

- Joined: Sat Feb 23, 2013 5:42 pm

- Location:

Re: Another Header issue.

Here are Elston 1 5/8" tubing off the head before stepping. Of course, these aren't catalog headers.Casper393W wrote: ↑Thu Mar 15, 2018 5:57 pm Hey folks,. I know we have a topic going on headers but I have a different problem... I'm building a 393w with David Vizard and I am putting it in a 71 F100. My question is...what is the most power you guys have seen 1.625 headers support? There isn't a company out there that manufacturers a 1 3/4 or 1 7/8 header for a Windsor engine in a F100... So I'm stuck with a set of Hedman street headers until I can get some custom made.

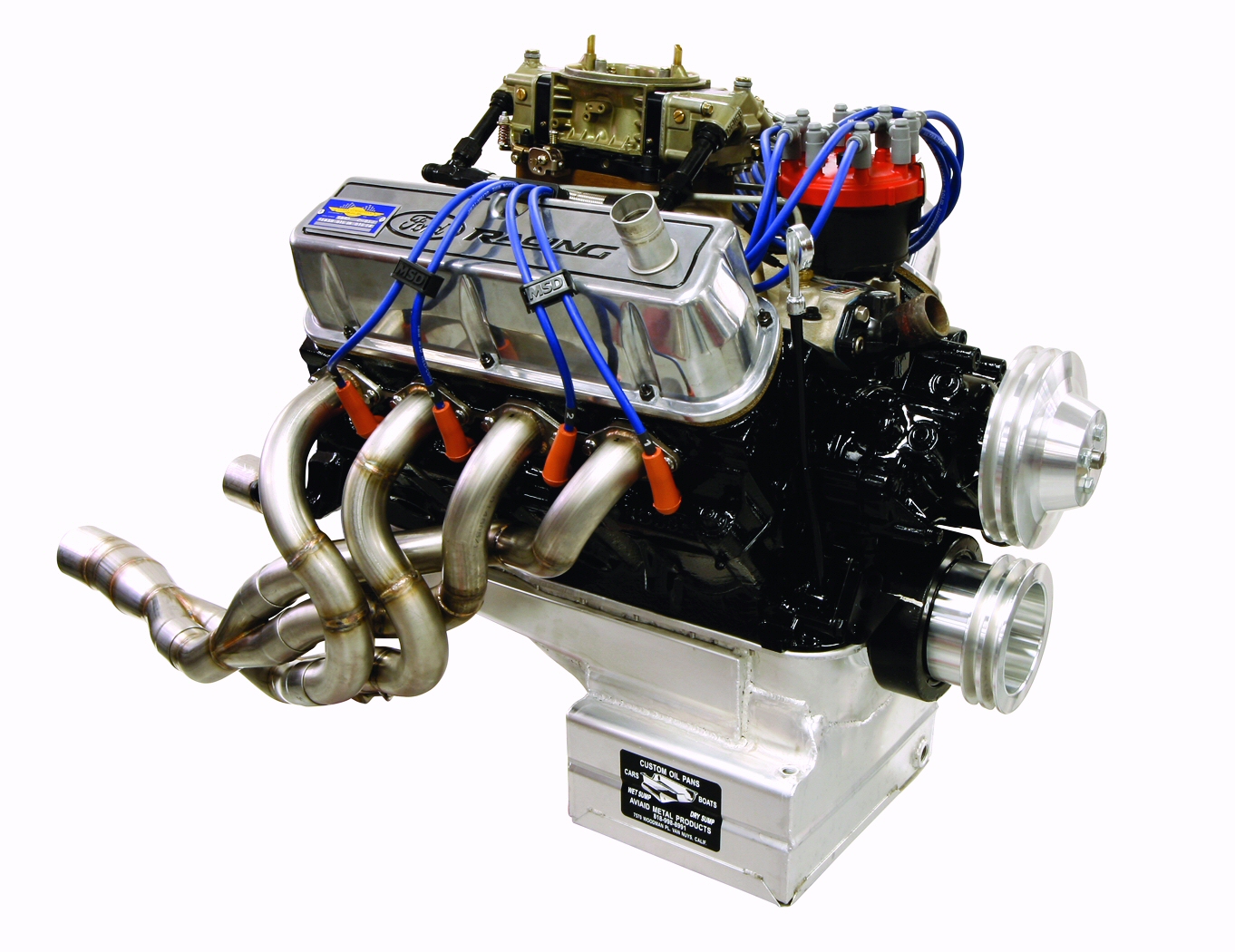

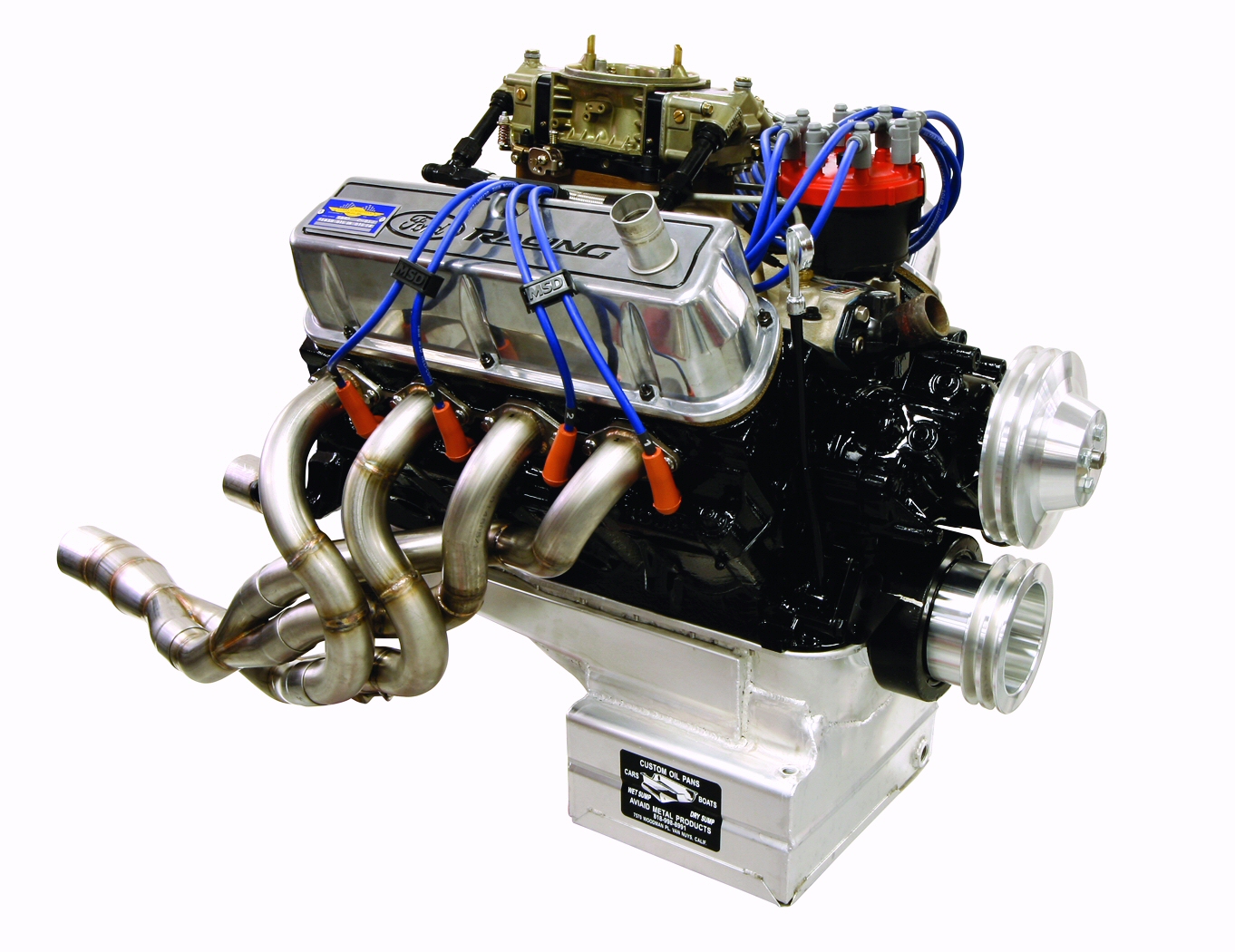

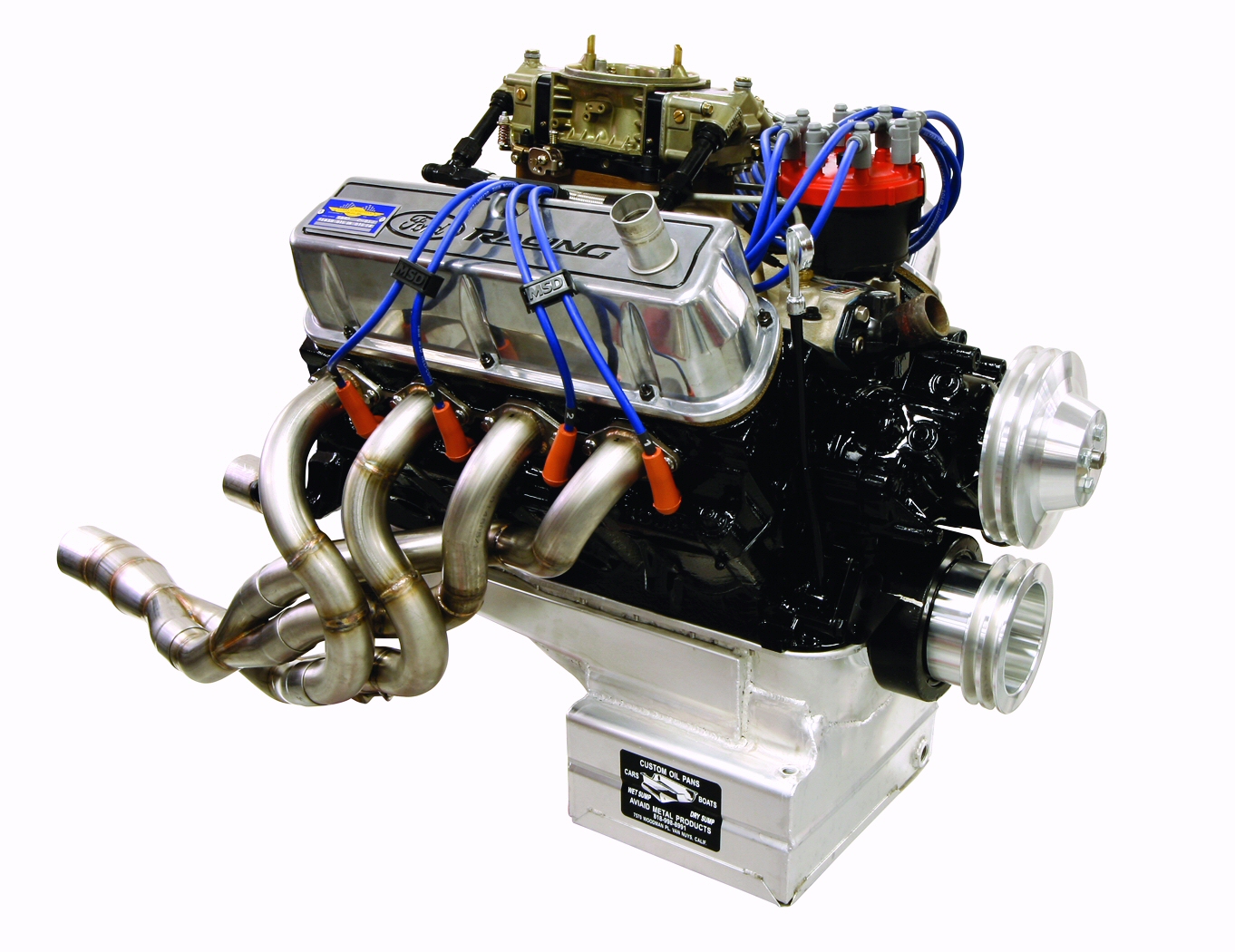

Here is a pic of the engine

Let me know what you guys think!

It all eventually feeds into a single 3" tailpipe to exit.I would not be afraid at all of using 1.625 at all off an even larger port area. I do it all the time for Cobra Automotive and their nostalgia mustangs and cobras. 1.63@8-1.75@10, 2" secondary for 12-14", (not a typo) and a 2.25" choke at the final collector. 620hp no problem and all sorts of bottom end. Especially for such a small motor and road racing

In-car. The Camaro is also out of the same shop

Boss 302 Mustang: https://www.youtube.com/watch?v=t28GFX6H2tA

Z/28 Camaro: https://www.youtube.com/watch?v=HH8IPGwOLMg

It's also interesting to hear the difference between the Chevy and Ford with what is essentially the same engine specs.

The typical off the shelf catalog header will not work with those diameters.

-Bob

-

statsystems

- Guru

- Posts: 1508

- Joined: Sun Apr 03, 2016 1:17 am

- Location:

Re: Another Header issue.

Calvin does impeccable work. The problem with those is they don't look like they would fit any stock front clip. If you have the room to make them that long before the first bend that certainly helps.hoffman900 wrote: ↑Fri Mar 16, 2018 5:17 pmHere are Elston 1 5/8" tubing off the head before stepping. Of course, these aren't catalog headers.Casper393W wrote: ↑Thu Mar 15, 2018 5:57 pm Hey folks,. I know we have a topic going on headers but I have a different problem... I'm building a 393w with David Vizard and I am putting it in a 71 F100. My question is...what is the most power you guys have seen 1.625 headers support? There isn't a company out there that manufacturers a 1 3/4 or 1 7/8 header for a Windsor engine in a F100... So I'm stuck with a set of Hedman street headers until I can get some custom made.

Here is a pic of the engine

Let me know what you guys think!

It all eventually feeds into a single 3" tailpipe to exit.I would not be afraid at all of using 1.625 at all off an even larger port area. I do it all the time for Cobra Automotive and their nostalgia mustangs and cobras. 1.63@8-1.75@10, 2" secondary for 12-14", (not a typo) and a 2.25" choke at the final collector. 620hp no problem and all sorts of bottom end. Especially for such a small motor and road racing

In-car. The Camaro is also out of the same shop

Boss 302 Mustang: https://www.youtube.com/watch?v=t28GFX6H2tA

Z/28 Camaro: https://www.youtube.com/watch?v=HH8IPGwOLMg

It's also interesting to hear the difference between the Chevy and Ford with what is essentially the same engine specs.

The typical off the shelf catalog header will not work with those diameters.

I'd like to see the cam specs for that engine...and a few other things...

-

hoffman900

- HotPass

- Posts: 3457

- Joined: Sat Feb 23, 2013 5:42 pm

- Location:

Re: Another Header issue.

Bill-C should be able to confirm this: http://store.cobraautomotive.com/mechan ... race-only/

http://store.cobraautomotive.com/compet ... t-headers/

That’s an easy EMC rule to torture.

I’m not sure if they trim anything away, but those chassis are “stock” save for Penske shocks, different springs, sway bars, etc.Mechanical Roller Race Only

Intake .706 Lift - 255° Duration @ .050

Exhst .643 Lift - 253° Duration @ .050

106° Lobe Separation

Intake, porting, headers, low gears, rough idle,

manual trans, high compression

And “off the shelf” Elston headersCompetition engines move so much air at high RPM that proper application of header design theory is crucial. With racers spending large sums of money on modified induction systems, it is only logical that an equal amount of attention be given to the exhaust “exit” side of the equation. Our competition road race headers are built exclusively for us under a proprietary arrangement with one of the cutting-edge manufactures in the industry. It’s all about gas particle movement and pressure wave activity. Our designer spent over 17 years in NASCAR Cup Racing, pioneering several advancements in exhaust technology in that field. The result is that these headers are the ultimate small block Ford road race headers available. Multiple step primary tubes mated with special merge-style collector is the secret to our header design. In back-to-back Dyno tests, these headers consistently show as much as a 30 HP increase over the leading race headers. An absolute must on all 500+ horsepower 289-302 road race engines. All competition headers are built to order. Headers for Mustangs must be specified for hydraulic or mechanical clutch applications. Cobra headers are sold without side pipes which must be specified separate.

http://store.cobraautomotive.com/compet ... t-headers/

That’s an easy EMC rule to torture.

-Bob

-

groberts101

- Guru

- Posts: 1980

- Joined: Sat Mar 08, 2008 3:08 pm

- Location: Minneapolis

Re: Another Header issue.

Those look horrible! Look at all those bends and overly restrictive choke points!

Good stuff here.

I believe the main rule for primary sizing on twisted and contorted headers, which is probably 95% of cookie cutter shelf headers, being squashed into tighter engine bays is to forego some velocity in hopes of reduced flow losses needed to meet the expected power peaks . Hard to near impossible to get an optimum design that achieves that perfect balance of optimized velocity with sufficient flow and we inevitably just do what we have to do to attach the stupid mufflers on the thing.

Good stuff here.

I believe the main rule for primary sizing on twisted and contorted headers, which is probably 95% of cookie cutter shelf headers, being squashed into tighter engine bays is to forego some velocity in hopes of reduced flow losses needed to meet the expected power peaks . Hard to near impossible to get an optimum design that achieves that perfect balance of optimized velocity with sufficient flow and we inevitably just do what we have to do to attach the stupid mufflers on the thing.

-

hoffman900

- HotPass

- Posts: 3457

- Joined: Sat Feb 23, 2013 5:42 pm

- Location:

Re: Another Header issue.

That's absolutely what is happening.

Calvin

BILL-C is involved with those Cobra Automotive engines from the other thread:

Calvin

It helps to not think in terms of "port" verses "tubing". The tube becomes the port. You do not introduce tight radius for the same reason you do not do it in the ports. The only way to overcome the loss, especially in the transition area and the first 6-8" of the header, is by using larger tubing diameters. And the problem keeps going down the toilet. "Well, if we made a bigger header, it would make a little more power",(because we overcome the flow loss up front). But the larger tube now needs an even tighter radius to clear the obstruction... And you are now so far away from what the engine wants for a header, it really does not matter what you do from there, the engine won't respond to changes. The smallest diameter tube allows for the largest radius. It can even be smaller in area than the port, especially if it allows a larger radius. (the application can trump this though) The first 6-8" of the header is just as important as the first 3 or 4" in the cylinder head. The same rules and thinking that a head porter uses apply to the header. Most headers I see break all the rules. The last thought is this, the reason the first 10" of the exhaust track is so important as opposed to just the port in the casting? The gas particles, the mass...only gets that far before the ex valve closes behind it, and it no longer is connected to its pressure differential, if you will. At that point in the exhaust track, everything changes. But anything you do to the "particulate-mass" flow in the port while the valve is open that violates flow, will cost you power and you can not get it back. You want to get the "mass-flow" as far away from the ex valve and the cylinder as you can. Larger "anything" in this area does not usually help. I do understand that many applications force the header to break all these rules and larger is the only answer if you need maximum power.

I don't think that is off topic at all. Back in the old days, (50's through the 80's) bigger headers, (bigger everything for that matter), the introduction of Superflow dynos to the average engine shop along with the "flow bench" in the hands of anyone with a grinder...the quest was for the maximum hp at the top of the curve. The loss of bottom end power was ignored when you could make a big increase upstairs. In most types of racing during those periods, the increase was definitely there and measurable at the track. Over the last 20 years or so, we have found,(with I'd like to think some input from me) that we only have to make things like headers as big as they need to be, in fact the work is in finding out how small can we make the back-door of an engine without losing power. This is much more to do with flow than tuning. When we find that a 1.75" tube on a 6" radius can flow the same as a 1.88" tube on a 3" radius it should change how you build headers, not to mention how large the exhaust port needs to be at the exhaust flange where the header starts... The essential realization that seems missing (to me) from tuners' understanding of the function of an exhaust system is, the larger you make a given system, what you are doing is letting the the full weight of the atmospheric pressure get to the back of the engine sooner and easier. This no longer the way to make more power. If you can see a choke on a merged collector as a valve or orifice through which the atmospheric pressure has to traverse to get to the engine, you may see that the thing to work towards is how small a choke can we get a given engine's exhaust gases through before you start losing power. And another thing to keep in mind is that in most applications I have seen, decreasing choke diameters (and the whole header for that matter, ie smaller and shorter tubes) is not a flow issue but rather a engines inability to deal with the reduction in pressure it sees on the exhaust side for the given cam timing. I think it is important to remember that only one cylinder is firing at a time, whether you like it or not. When I was able to reintroduce a 421 header design in Winston Cup back in the middle 90's, we quickly learned that ANY421 header could use at least a 1/4" smaller final collector choke while making more overall power. Having been learning about the ins and outs of this for many years, I can not help but have to look at the exhaust port itself and what I am given to work with from my customers in terms of area's. There are quite a few cylinder head guys out there that have heard my spiel, some respond and some don't but the bottom line is that I have never seen a exhaust port that I liked. An exhaust port needs to be designed from the point of view of the whole header design and system that it will be using. I am going on because your post just puts forward the grand confusion around exhaust valve vs header size and how it all works. Thanks for the input.

Which one do you (collective you) think will work better?When the tube is smaller than the port, you have the ability to design the flange so as to put the excess tubing area where you want it. It goes on the bottom. It should come as common thinking that the port should be sized to available tubing sizes. Any head porter that does not take that into consideration when looking at the exhaust side should be avoided. IMO. Obviously if the casting was designed with a weird shape there is not much you can do, but there is no excuse, IMO, for a port to not be round and the same diameter as the id of tubing, does not matter what the flow bench says. If you don't make it round, I will...in less than 1/2". Machined flanges that make the transition are an answer but I know very few people that will go to that expense except Cup and F1). And using a 1/2" or 3/4" thick adapter on the head may seem a nice answer, it isn't if you have to use a tighter radius to clear things you are now that much closer to...

BILL-C is involved with those Cobra Automotive engines from the other thread:

BILL-C wrote: ↑Fri Mar 16, 2018 10:05 pm I have multiple sets of sb ford dyno headers that Calvin made for us. They are configured in a way that allows us to experiment with secondary pipe lengths and swap firing order easily. We have made 650+ hp with the dyno configuration of the headers in the picture posted by hoffman 900. They match or beat the lower end power of any 1.625 dia straight tube header and beat the top end power of any 1.75 header we have ever tested. They are far superior to any "catalog" header .

-Bob

-

groberts101

- Guru

- Posts: 1980

- Joined: Sat Mar 08, 2008 3:08 pm

- Location: Minneapolis

Re: Another Header issue.

I just wrote in another thread about my appreciation for UDHarold's ability and willingness to share much of his life learned work and have to give Calvin that same kind of love for his contributions to others as well as my own personal learning curve. I think as I get older myself I have started to realize that some of these guys may feel similar in that the newer generations are using laptops and sims rather than their blood sweat and tears to really drive some of this knowledge home and much of it could be lost forever when some of these bright minds are no longer with us. Use a GPS too much and you never really learn the exact route to use when it's not available to us.

Ed Henniman was another gentleman who believed and contributed to similar "velocity is king" thought processes when it came time to develop a header for any specific chassis/ engine combo. He'd look at the other guys stuff and immediately set out to shrink it in hopes of making more average power within the curve. Although it's a whole other subject in itself.. he was also a HUGE proponent for equal lengths too. Next to near impossible to actually achieve in the real world of an OEM configured engine bay but he said without them you are essentially tuning the motor for a happy meduim between all cylinders as many cylinders will have differing needs because each cylinders individual tune may be improved while others are simultaneously compromised. Common plenum induction systems share this same fate as well and sometimes those two variable length systems can wreak havoc on each other when seeking the optimized tune. Typical engines are usually boiled down to the laws of averages and we simply try to find a happy medium to prevent any one cylinder from becoming too unhappy with its fate compared to the rest.

Ed Henniman was another gentleman who believed and contributed to similar "velocity is king" thought processes when it came time to develop a header for any specific chassis/ engine combo. He'd look at the other guys stuff and immediately set out to shrink it in hopes of making more average power within the curve. Although it's a whole other subject in itself.. he was also a HUGE proponent for equal lengths too. Next to near impossible to actually achieve in the real world of an OEM configured engine bay but he said without them you are essentially tuning the motor for a happy meduim between all cylinders as many cylinders will have differing needs because each cylinders individual tune may be improved while others are simultaneously compromised. Common plenum induction systems share this same fate as well and sometimes those two variable length systems can wreak havoc on each other when seeking the optimized tune. Typical engines are usually boiled down to the laws of averages and we simply try to find a happy medium to prevent any one cylinder from becoming too unhappy with its fate compared to the rest.

Re: Another Header issue.

That is one of the many different cams we use. The most advanced [ and expensive] engines use something a little different, but are not safe to sell to the average joe. Too many ways to hurt themselves! Those headers fit the stock chassis awesome. Very easy to work on the car too. The whole package is very well thought out. A few years ago one of the house cars broke a lifter saterday morning in practice at the us vintage grand prix at watkins glen 3 hours before the car had to be back out on track in qualifying race for the main event on sunday. 3 of us swapped engine and ate lunch with time to spare.hoffman900 wrote: ↑Fri Mar 16, 2018 6:43 pm Bill-C should be able to confirm this: http://store.cobraautomotive.com/mechan ... race-only/

I’m not sure if they trim anything away, but those chassis are “stock” save for Penske shocks, different springs, sway bars, etc.Mechanical Roller Race Only

Intake .706 Lift - 255° Duration @ .050

Exhst .643 Lift - 253° Duration @ .050

106° Lobe Separation

Intake, porting, headers, low gears, rough idle,

manual trans, high compression

And “off the shelf” Elston headersCompetition engines move so much air at high RPM that proper application of header design theory is crucial. With racers spending large sums of money on modified induction systems, it is only logical that an equal amount of attention be given to the exhaust “exit” side of the equation. Our competition road race headers are built exclusively for us under a proprietary arrangement with one of the cutting-edge manufactures in the industry. It’s all about gas particle movement and pressure wave activity. Our designer spent over 17 years in NASCAR Cup Racing, pioneering several advancements in exhaust technology in that field. The result is that these headers are the ultimate small block Ford road race headers available. Multiple step primary tubes mated with special merge-style collector is the secret to our header design. In back-to-back Dyno tests, these headers consistently show as much as a 30 HP increase over the leading race headers. An absolute must on all 500+ horsepower 289-302 road race engines. All competition headers are built to order. Headers for Mustangs must be specified for hydraulic or mechanical clutch applications. Cobra headers are sold without side pipes which must be specified separate.

http://store.cobraautomotive.com/compet ... t-headers/

That’s an easy EMC rule to torture.

Carlquist Competition Engines

-

groberts101

- Guru

- Posts: 1980

- Joined: Sat Mar 08, 2008 3:08 pm

- Location: Minneapolis

Re: Another Header issue.

That is one of the many different cams we use. The most advanced [ and expensive] engines use something a little different, but are not safe to sell to the average joe. Too many ways to hurt themselves! Those headers fit the stock chassis awesome. Very easy to work on the car too. The whole package is very well thought out. A few years ago one of the house cars broke a lifter saterday morning in practice at the us vintage grand prix at watkins glen 3 hours before the car had to be back out on track in qualifying race for the main event on sunday. 3 of us swapped engine and ate lunch with time to spare.

[/quote]

Hi Bill. Sorry for the sidetrack here.. but can you give an idea what power you guys squeek out of the 289/302's with the dual plane setup? And which manifold being used? Old Cobra style repops(forgot part #) or maybe the Edelbrock airgap?

Thanks,

Greg

PS. Inline with this threads topic.. what impact does the dual plane have on final header choice for your engines?

Seems safe to assume the dual planes sharper ve drops in the higher rpm ranges would favor slight header design changes.

Last edited by groberts101 on Sat Mar 17, 2018 2:26 pm, edited 2 times in total.

-

hoffman900

- HotPass

- Posts: 3457

- Joined: Sat Feb 23, 2013 5:42 pm

- Location:

Re: Another Header issue.

Part of Calvin’s genius with the headers is each port has its own flange. When you disassemble one of his headers, it looks like a pile of welded tubes. Then you can assemble it in a sequence to get everything to fit. He does not look at an engine bay the same way most people do. The science is in the function, but he’s a real artist in the application.

-Bob

Re: Another Header issue.

Hi Bill. Sorry for the sidetrack here.. but can you give an idea what power you guys squeek out of the 289/302's with the dual plane setup? And which manifold being used? Old Cobra style repops(forgot part #) or maybe the Edelbrock airgap?groberts101 wrote: ↑Sat Mar 17, 2018 2:22 pmThat is one of the many different cams we use. The most advanced [ and expensive] engines use something a little different, but are not safe to sell to the average joe. Too many ways to hurt themselves! Those headers fit the stock chassis awesome. Very easy to work on the car too. The whole package is very well thought out. A few years ago one of the house cars broke a lifter saterday morning in practice at the us vintage grand prix at watkins glen 3 hours before the car had to be back out on track in qualifying race for the main event on sunday. 3 of us swapped engine and ate lunch with time to spare.

Thanks,

Greg

PS. Inline with this threads topic.. what impact does the dual plane have on final header choice for your engines?

Seems safe to assume the dual planes sharper ve drops in the higher rpm ranges would favor slight header design changes.

[/quote]

The different sanctioning bodies have different engine rules. The majority of the races are run in SVRA trim, which requires performer rpm intake. Airgap version is not legal.The oe cobra style intake isn't very good compared to edelbrock. With heavily modified perf rpm equipped 289 we make 585hp and 302's make a tick over 600 on my DTS dyno. Because of the fact we are always changing intakes, we only slightly bias the header design to favor the dual plane intakes. The most important races of the year are run under SVRA rules, which require the dual planes. The single plane intake numbers are approx 15-18 hp higher . Because of the earlier power curve, many of the drivers leave the dual plane intake on for the shorter, more technical tracks even when single plane allowed. Cams are typically slightly biased for dual plane intakes also.I have a huge investment into R+D on these dual plane intakes and power drop off isn't as bad as you might think. If we ran only single plane intakes, we would run higher rpm, more gear, and need slightly different headers and cams.

Carlquist Competition Engines

-

Casper393W

- Pro

- Posts: 422

- Joined: Wed Jul 06, 2016 7:18 am

- Location:

Re: Another Header issue.

I want to thank you guys for sharing your knowledge! This kinda of talk here is why I fell in love with Speed talk.

Not the bashing of people and their idea's!

I feel much better now about my headers here is a pic of what I will be running

Not the bashing of people and their idea's!

I feel much better now about my headers here is a pic of what I will be running

You do not have the required permissions to view the files attached to this post.

-

groberts101

- Guru

- Posts: 1980

- Joined: Sat Mar 08, 2008 3:08 pm

- Location: Minneapolis

Re: Another Header issue.

lol.. man it's hard to quote all the quotes around here!BILL-C wrote: ↑Sat Mar 17, 2018 3:04 pmThe different sanctioning bodies have different engine rules. The majority of the races are run in SVRA trim, which requires performer rpm intake. Airgap version is not legal.The oe cobra style intake isn't very good compared to edelbrock. With heavily modified perf rpm equipped 289 we make 585hp and 302's make a tick over 600 on my DTS dyno. Because of the fact we are always changing intakes, we only slightly bias the header design to favor the dual plane intakes. The most important races of the year are run under SVRA rules, which require the dual planes. The single plane intake numbers are approx 15-18 hp higher . Because of the earlier power curve, many of the drivers leave the dual plane intake on for the shorter, more technical tracks even when single plane allowed. Cams are typically slightly biased for dual plane intakes also.I have a huge investment into R+D on these dual plane intakes and power drop off isn't as bad as you might think. If we ran only single plane intakes, we would run higher rpm, more gear, and need slightly different headers and cams.groberts101 wrote: ↑Sat Mar 17, 2018 2:22 pm

Hi Bill. Sorry for the sidetrack here.. but can you give an idea what power you guys squeek out of the 289/302's with the dual plane setup? And which manifold being used? Old Cobra style repops(forgot part #) or maybe the Edelbrock airgap?

Thanks,

Greg

PS. Inline with this threads topic.. what impact does the dual plane have on final header choice for your engines?

Seems safe to assume the dual planes sharper ve drops in the higher rpm ranges would favor slight header design changes.

Thanks for the reply, Bill. I'm nearly flabbergasted how little you give up with that DP manifold. And I rarely EVER use that word!

I would have easily layed cash you would be giving up near 40 horsepower from the SP setup. Glad I didn't get into a pissing match about it before your reply!

Heck, I was so worried my Kaase P38 headed 342" road race deal would give up too much power over 7,000 rpm that I bought a bigger/taller 351W airgap to pump up the volume. Your motors make me wonder if.. I'll be giving up too much torque below peak?

Granted your R&D and combo refinement is key there.. but leads me to believe you could probably wring out near 700 from my DP combo with enough time and cash investment. These Kaase heads won't need nearly as much cam and I plan on keeping peak power at 7,600-7,800 with some additional overrev potential factored in.. just in case I'm getting beat.