Pipemax details I am using to build my exhaust and intake.

199.807 Cubic Inches @ 6100 RPM with 103.00 % Volumetric Efficiency PerCent

Required Intake Flow CFM @28 in. = 154.1 to 163.2 at .530 inch Valve Lift

Required Exhaust Flow CFM @28 in. = 123.4 to 133.7 at .484 inch Valve Lift

600 RPM/Sec Dyno Test Lowest Low Average Best

Peak HorsePower 223.8 228.5 231.4 234.3

Peak Torque Lbs-Ft 212.5 218.1 220.4 223.7

HorsePower per CID 1.120 1.143 1.158 1.173

Torque per Cubic Inch 1.063 1.091 1.105 1.119

BMEP in psi 160.4 164.6 166.7 168.8

Carb CFM at 1.5 in Hg. 363 404 425 445

Recommended Intake Valve Lift to prevent Choke = .530 Lift @ 6100 RPM

Recommended Exhaust Valve Lift to prevent Choke = .484 Lift @ 6100 RPM

Recommended Minimum Normal Maximum Time-Area-Duration Lifts

Intake Valve Lift = 0.4705 0.5300 0.5830 0.6304 0.6645 0.6986

Exhaust Valve Lift = 0.4450 0.4837 0.5321 0.5736 0.6095 0.6455

IntOpen= -.50 IntClose= 41.50 ExhOpen= 41.50 ExhClose= -0.50

Intake Duration @ .050 = 221.00 Exhaust Duration @ .050 = 221.00

Intake CenterLine = 111.00 Exhaust CenterLine = 111.00

Compression Duration= 138.50 Power Duration = 138.50

OverLap Duration = -1.00 Lobe Separation Angle (LSA)= 111.00

Camshaft Straight Up = 0.00 degrees Cylinder Ignition Interval= 120 deg.

-- Operating RPM Ranges of various Components --

Best estimate RPM operating range from all Components = 3982 to 5982

Intake Flow CFM @28inches RPM Range from Flow CFM only = 4042 to 6042

Intake and Exhaust Systems operating RPM Range = 3590 to 5590

Intake and Exhaust Time-Area operating RPM Range = 2813 to 4813

Camshaft's Intake and Exhaust Lobes operating RPM range = 3466 to 5466

Intake Valve Curtain Time-Area at 0.474 Lift RPM Range = 3456 to 5456

Exhaust Valve Curtain Time-Area at 0.474 Lift RPM Range = 3977 to 5977

Intake Valve Close RPM = 5565 Exhaust Valve Open RPM = 5171

Intake System RPM = 5552 Exhaust System RPM = 5629

Intake Time-Area RPM = 4586 Exhaust Time-Area RPM = 5041

Intake Mach Z-Factor = 0.542689 Exhaust Mach Z-Factor = 0.651385

Intake Z-Factor Lift = 0.535906 Exhaust Z-Factor Lift = 0.467813

Curtain Area -to- Valve Area Convergence Intake Valve Lift inch= .414

Curtain Area -to- Valve Area Convergence Exhaust Valve Lift inch= .345

Target EGT= 1422.7 degrees F at end of 4 second 600 RPM/Sec Dyno accel. test

Octane (R+M)/2 Method = 89.1 to 90.6 Octane required range

Air Standard Efficiency = 58.83315 % for 8.900:1 Compression Ratio

------- Piston Motion Data -------

Average Piston Speed (FPM)= 3322.47 in Feet Per Minute

Maximum Piston Speed (FPM)= 5405.981 occurs at 75.84311 Degrees ATDC

Piston Depth at 75.843 degree ATDC= 1.4450 inches Cylinder Volume= 241.3 CC

Maximum TDC Rod Tension GForce= 2192.3804 G's

Maximum BDC Rod Compression GForce= 1261.5373 G's

----- Engine Design Specifications -----

( English Units ) ( per each Valve Sq.Inch area )

Engine Size CID = 199.807 Intake Valve Net Area = 2.089

CID per Cylinder = 33.301 Intake Valve Dia. Area = 2.149

Rod/Stroke Ratio = 1.855 Intake Valve Stem Area = 0.060

Bore/Stroke Ratio = 1.102 Exhaust Valve Net Area = 1.413

Int Valve/Bore Ratio = 0.459 Exhaust Valve Dia. Area = 1.491

Exh Valve/Bore Ratio = 0.383 Exhaust Valve Stem Area = 0.078

Exh/Int Valve Ratio = 0.833 Exh/Int Valve Area Ratio = 0.694

Intake Valve L/D Ratio= .287 Exhaust Valve L/D Ratio= .344

CFM/Sq.Inch = 71.7 to 75.9 CFM/Sq.Inch =82.5 to 86.1

Intake Valve Margin CC's Exhaust Valve Margin CC's

1.00 CC = 0.0284 1.00 CC = 0.0409

0.50 CC = 0.0142 0.50 CC = 0.0205

0.25 CC = 0.0071 0.25 CC = 0.0102

0.10 CC = 0.0028 0.10 CC = 0.0041

- Induction System Tuned Lengths - ( Cylinder Head Port + Manifold Runner )

1st Harmonic= 31.713 (usually this Length is never used)

2nd Harmonic= 17.999 (some Sprint Engines and Factory OEM's w/Injectors)

3rd Harmonic= 12.566 (ProStock or Comp SheetMetal Intake • best overall HP )

4th Harmonic= 9.890 (Single-plane Intakes , less Peak Torque • good HP )

5th Harmonic= 8.025 (Torque is reduced, even though Tuned Length)

6th Harmonic= 6.751 (Torque is reduced, even though Tuned Length)

7th Harmonic= 5.827 (Torque is greatly reduced, even though Tuned Length)

8th Harmonic= 5.125 (Torque is greatly reduced, even though Tuned Length)

Note> 2nd and 3rd Harmonics typically create the most Peak Torque

4th Harmonic is used to package Induction System underneath Hood

Plenum Runner Minimum Recommended Entry Area = 1.644 to 1.849 Sq.Inch

Plenum Runner Average Recommended Entry Area = 1.890 Sq.Inch

Plenum Runner Maximum Recommended Entry Area = 1.930 to 2.284 Sq.Inch

Minimum Plenum Volume CC = 466.1 ( typically for Single-Plane Intakes )

Minimum Plenum Volume CID= 28.4 ( typically for Single-Plane Intakes )

Maximum Plenum Volume CC = 3274.2 ( typically for Tunnel Ram Intakes )

Maximum Plenum Volume CID= 199.8 ( typically for Tunnel Ram Intakes )

--- Cross-Sectional Areas at various Intake Port Velocities (@ 28 in.) ---

150 FPS at Intake Valve Curtain Area= 2.463 sq.in. at .474 Lift

172 FPS at Intake Valve OD Area and at Convergence Lift = .414

212 FPS 90% PerCent Rule Seat-Throat Velocity CSA= 1.740 sq.in.

--- 6100 RPM Intake Cross-sectional areas in Square Inches ---

350 FPS CSA= 1.056 Port has Sonic-Choke with HP Loss ( too fast FPS )

330 FPS CSA= 1.121 Port may have Sonic-Choke with HP Loss ( too fast FPS )

311 FPS CSA= 1.189 Highest useable Port velocity ( possible HP loss )

300 FPS CSA= 1.233 Smallest Port CSA ( Hi Velocity FPS • good TQ and HP )

285 FPS CSA= 1.298 Smallest Port CSA ( very good TQ and HP combination )

260 FPS CSA= 1.422 Recommended average Intake Port CSA (very good TQ and HP)

250 FPS CSA= 1.479 Largest recommended average Intake Port CSA ( good HP )

240 FPS CSA= 1.541 Largest recommended average Intake Port CSA (less Peak TQ)

235 FPS CSA= 1.574 Largest recommended Intake Port Gasket Entry area CSA

225 FPS CSA= 1.644 Largest Intake Port Gasket Entry CSA ( Slow FPS )

215 FPS CSA= 1.720 Possible Torque Loss with Reversion ( Slow FPS )

210 FPS CSA= 1.761 Torque Loss + Reversion possibility ( too slow FPS )

200 FPS CSA= 1.849 Torque Loss + Reversion possibility ( too slow FPS )

Note : these are calculated average Port cross-sectional areas and FPS

--- Cross-Sectional Areas at various Exhaust Port Velocities (@ 28 in.) ---

144 FPS at Exhaust Valve Curtain Area= 2.052 sq.in. at .474 Lift

199 FPS at Exhaust Valve OD Area and at Convergence Lift = .345

245 FPS 90% PerCent Rule Seat-Throat Velocity CSA= 1.208 sq.in. at 6100 RPM

--- 6100 RPM Exhaust Cross-sectional areas in Square Inches ---

435 FPS CSA= 0.681 Sonic Choke at Throat Area (too fast FPS velocity)

380 FPS CSA= 0.780 Sonic Choke at Throat Area (possibly too fast FPS)

350 FPS CSA= 0.846 Exhaust Port has Sonic-Choke with HP Loss (too fast)

330 FPS CSA= 0.898 Exhaust Port has Sonic-Choke with HP Loss (too fast)

311 FPS CSA= 0.952 smallest Exhaust Port ( very high velocity FPS )

300 FPS CSA= 0.987 smallest recommended Exhaust Port (Hi velocity)

285 FPS CSA= 1.039 smallest recommended Exhaust Port (Hi velocity)

265 FPS CSA= 1.118 Recommended average Exhaust Port CSA

250 FPS CSA= 1.185 Recommended average Exhaust Port gasket area

240 FPS CSA= 1.234 Recommended largest Exhaust Port gasket area

225 FPS CSA= 1.317 Largest Exhaust Port Exit gasket area (Slow FPS)

210 FPS CSA= 1.411 Largest Exhaust Port Exit gasket area (Slow FPS)

190 FPS CSA= 1.559 Torque Loss + Reversion + Scavenging loss (too slow FPS)

180 FPS CSA= 1.646 Torque Loss + Reversion + Scavenging loss (too slow FPS)

Note : these are calculated average Port cross-sectional areas and FPS

Valve Intake Exhaust Curtain Area Cross-Sect Area Minimum Flow

Lift Choke Choke Square Inches 280FPS 280FPS CFM @ 28 In

inches RPM RPM Intake Exhaust Intake Exhaust Int Exh

.050 576 630 0.260 0.216 0.125 0.100 14.5 11.6

.075 863 946 0.390 0.325 0.187 0.150 21.8 17.5

.100 1151 1261 0.520 0.433 0.249 0.200 29.1 23.3

.125 1439 1576 0.650 0.541 0.312 0.250 36.3 29.1

.150 1727 1891 0.779 0.649 0.374 0.299 43.6 34.9

.175 2014 2207 0.909 0.758 0.436 0.349 50.9 40.8

.200 2302 2522 1.039 0.866 0.498 0.399 58.1 46.6

.225 2590 2837 1.169 0.974 0.561 0.449 65.4 52.4

.250 2878 3152 1.299 1.082 0.623 0.499 72.7 58.2

.275 3165 3468 1.429 1.191 0.685 0.549 80.0 64.0

.300 3453 3783 1.559 1.299 0.748 0.599 87.2 69.9

.325 3741 4098 1.689 1.407 0.810 0.649 94.5 75.7

.350 4029 4413 1.819 1.515 0.872 0.699 101.8 81.5

.375 4316 4729 1.949 1.623 0.935 0.749 109.0 87.3

.400 4604 5044 2.078 1.732 0.997 0.798 116.3 93.2

Valve Intake Exhaust Curtain Area Cross-Sect Area Minimum Flow

Lift Choke Choke Square Inches 280FPS 280FPS CFM @ 28 In

inches RPM RPM Intake Exhaust Intake Exhaust Int Exh

.425 4892 5359 2.208 1.840 1.059 0.848 123.6 99.0

.450 5180 5674 2.338 1.948 1.121 0.898 130.8 104.8

.475 5467 5990 2.468 2.056 1.184 0.948 138.1 110.6

.500 5755 6305 2.598 2.165 1.246 0.998 145.4 116.4

.525 6043 6620 2.728 2.273 1.308 1.048 152.6 122.3

.550 6331 6935 2.858 2.381 1.371 1.098 159.9 128.1

.575 6618 7251 2.988 2.489 1.433 1.148 167.2 133.9

.600 6906 7566 3.118 2.597 1.495 1.198 174.4 139.7

.625 7194 7881 3.248 2.706 1.558 1.248 181.7 145.6

.650 7482 8196 3.378 2.814 1.620 1.298 189.0 151.4

.675 7769 8512 3.507 2.922 1.682 1.347 196.3 157.2

Cylinder Ignition Interval = 120 degrees 6100 RPM Hertz frequency = 50.8 Hz

Target EGT= 1422.7 degrees F at end of 4 second 600 RPM/Sec Dyno accel. test

199.807 CID Exhaust System operating RPM Range from 4100 to 6600 RPM

--- Single Primary Pipe Specs --- ( Low to Mid-Range RPM Torque and HP )

Diameter= 1.482 to 1.607 Total Length= 29.5 to 32.1 inches long

--- 2-Step Primary Pipe Specs --- ( Low to Mid-Range RPM Torque and HP )

1st Step Dia. inches= 1.482 Length= 14.7 to 16.1

2nd Step Dia. inches= 1.607 Length= 14.7 to 16.1

--- 3-Step Primary Pipe Specs --- ( Low to Mid-Range Torque and Hi RPM HP )

1st Step Dia. inches= 1.482 Length= 14.7 to 16.1

2nd Step Dia. inches= 1.607 Length= 7.4 to 8.0

3rd Step Dia. inches= 1.732 Length= 7.4 to 8.0

--- Single Primary Pipe Specs --- ( Mid-Range TQ to Higher RPM Horsepower )

Diameter= 1.682 to 1.807 Total Length= 29.5 to 32.1 inches long

--- 2-Step Primary Pipe Specs --- ( Mid-Range TQ to Higher RPM Horsepower )

1st Step Dia. inches= 1.682 Length= 9.8 to 11.2

2nd Step Dia. inches= 1.807 Length= 19.7 to 21.0

--- 3-Step Primary Pipe Specs --- ( Higher RPM Horsepower, possible TQ loss )

1st Step Dia. inches= 1.682 Length= 9.8 to 11.2

2nd Step Dia. inches= 1.807 Length= 9.8 to 10.5

3rd Step Dia. inches= 1.932 Length= 9.8 to 10.5

--- Conventional Straight Tube Collector Specs ---

( TQ ) Diameter= 2.264 to 2.514 Best Length= 17.7 and also 35.3 inches

( HP ) Diameter= 2.514 to 3.014 Best Length= 17.7 and also 8.8 inches

--- Megaphone Collector Specs ---( Diffuser or Diverging Cone Shape )---

( TQ ) Diameter= 1.514 taper to 2.514 Best Length= 17.7 or 35.3 inches

( HP ) Diameter= 1.764 taper to 2.764 Best Length= 17.7 or 35.3 inches

H-Pipe= 17.7 X-Pipe= 70.6 distance behind end of Primary Tube ends

-- Total Exhaust System Tuned Lengths (Primary ends to TailPipe end) --

Best HP/TQ Tuned Collector Lengths= 17.7 , 35.3 , 70.6 , 141.3 inches long

Worst HP/TQ Loss Collector Lengths= 26.5 , 53.0 , 106.0 , 211.9 inches long

Note=> measured from where the Primary Pipes end inside the Collector to

the point the Collector or tailpipe exits into the atmosphere.

Note-> all Pipe Diameters are OD and based-off .0625 inch Pipe thickness

---- Primary Pipe's Harmonics ----

1st Harmonic = 128.1 inches long ... typically never used

2nd Harmonic = 48.9 inches long ... longest recommended

3rd Harmonic = 29.5 inches long ... highly recommended , best Torque Curve

4th Harmonic = 20.7 inches long ... shortest recommended

5th Harmonic = 15.7 inches long ... typically never used

6th Harmonic = 12.5 inches long ... typically never used

7th Harmonic = 10.2 inches long ... typically never used

8th Harmonic = 8.5 inches long ... typically never used

---- Collector's Harmonics (includes Intermediate, Muffler , TailPipe) ----

1st Harmonic = 141.3 inches long ... longest with Mufflers and TailPipes

2nd Harmonic = 70.6 inches long ... longest recommended with Mufflers

3rd Harmonic = 35.3 inches long ... more bottom-end Torque

4th Harmonic = 17.7 inches long ... highly recommended , best Torque Curve

5th Harmonic = 8.8 inches long ... reduced Torque , more top-end HP sometimes

6th Harmonic = 4.4 inches long ... reduced Torque , not recommended

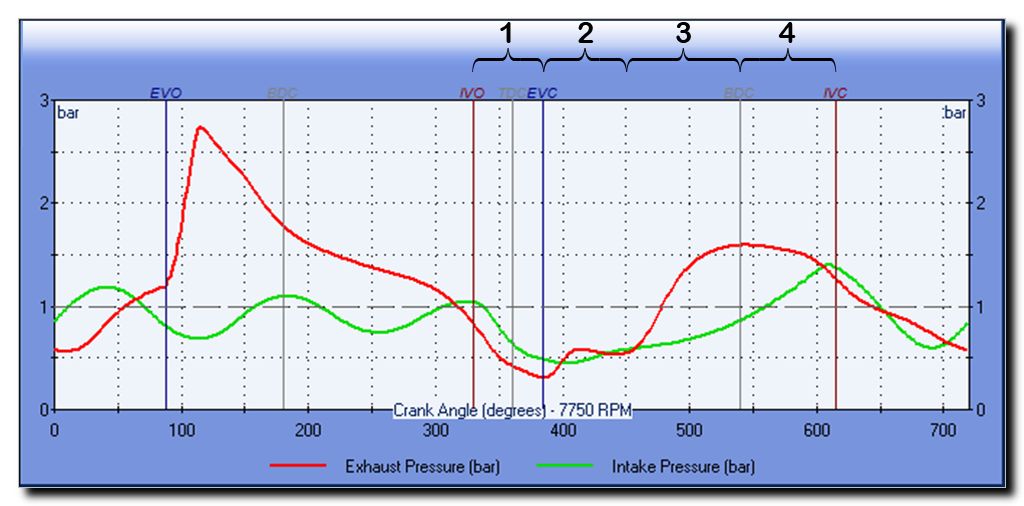

The coloured sections are the measurements I am going off for the intake. I have made the primaries to the merge collector for the exhaust already using the highlighted measurements above. I have erred on the small side in pipe size due to lack of room and it will be primarily a street car for the time being. I plan on going 2in from each merge for the lengths specified to the H pipe 17in if I can, (or 35in otherwise) where I will join the 2 pipes into a single 2.5in out the back.

This lot of specs is for a bigger cam than is currently in the engine, I have put smaller 34mm venturis in the IDFs for the current cam, will probably go up in size to the 36mm ones once the cams have been changed. Will just need to suck it and see for the manifolds / exhaust in the meantime as I cant afford to build those twice, lets hope cams come along quickly