Greenlight is the 8 hp you mentioned based on average dyno results?

Should this subject be moved to advanced tech, and I'll start browsing amateur tech????

Thanks; Randy

Moderator: Team

I am not sure about this, but I think it may be nessesary to consider the mass of the moving parts. (maybe this is in your calculation and I missed it) The reason I think this is that removing 10lbs from a 40lb crank will do more for acceleration than removing 10lbs from a 60lb crank.Not nearly as much as I expected. I went back and recalculated about 5 times thinking there was an error. I can’t find one, please anyone, let me know if I’ve made a mistake. I don’t think you could measure this on any kind of dyno.

No.The reason I think this is that removing 10lbs from a 40lb crank will do more for acceleration than removing 10lbs from a 60lb crank.

This may be true EXCEPT this is a FIXED acceleration, ie 600rpm/sec., controlled by the dyno. The difference in power shown on an accelerated dyno pull should be exactly the same (measurement error excluded). It takes a very specific amount of torque to accelerate a given weight or change in weight, at a given radius from center, at a fixed rate, regardless of the weight of the rest of the rotating assembly.SchmidtMotorWorks wrote:I am not sure about this, but I think it may be nessesary to consider the mass of the moving parts. (maybe this is in your calculation and I missed it) The reason I think this is that removing 10lbs from a 40lb crank will do more for acceleration than removing 10lbs from a 60lb crank.

Rick360 wrote:I finally had time to work this out.randy331 wrote:Thanks; Rick and packard;

With the power needed to accelerate a given weight,a given rpm. is a fixed amount.

Is there a formula to calculate the tq. or hp. required to accelerate 100 grams 600rpm in one second at 1.74" from the center of rotation?

Or is the formula one that I would need a calculator with the formula allready in it, so I just enter weight,distance from center,and acceleration rate and it gives me the answer?

Thanks; Randy

Excusse the spelling as my spell checker is at school.

First convert units to metric

100 gram bobweight change x 4 rod journals = 400gms = 0.4 kg

Crank radius to center of bobweight = 1.74” = 0.044196meters

Accel rate of 600rpm/s^2 = 62.83185 radians/sec^2

MOI = mass x radius^2 = 0.4 x .044196^2 = 0.000781 kg.m^2

Torque = MOI x Accel = 0.000781 kg.m^2 x 62.83185 rad/sec = 0.049092 Nm

Convert back to American/British units 0.049092 Nm = 0.036208 Lb/ft of Torque

HP at 5000rpm = (5000 x 0.036208)/5252 = 0.03447 HP to accelerate 400grams total bobweight at 600rpm/sec at 5000rpm

HP at 7000rpm = (7000 x 0.036208)/5252 = 0.048259HP HP to accelerate 400grams total bobweight at 600rpm/sec at 7000rpm

Not nearly as much as I expected. I went back and recalculated about 5 times thinking there was an error. I can’t find one, please anyone, let me know if I’ve made a mistake. I don’t think you could measure this on any kind of dyno.

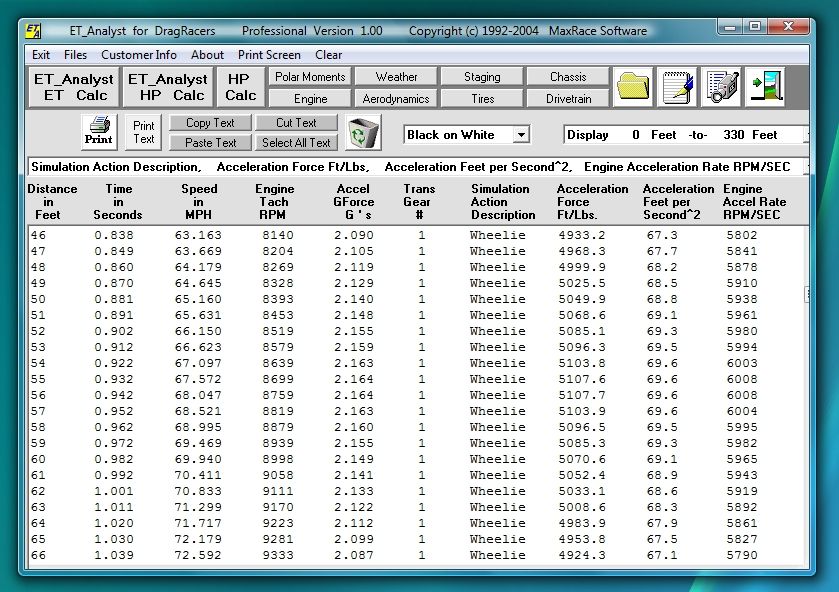

The calculated total rotating dyno (engine and dyno) MOI is approx 0.303 kg*m^2 using the HP difference (6hp @ 4500) from your 300rpm/s and 600rpm/s.

Rick

What is PMI?40.0 Lbs= PMI= 0.209316 Inertia HP Loss= 1.461109 @ 7000 RPM

60.0 Lbs= PMI= 0.313974 Inertia HP Loss= 2.191661

PMI = Polar Moment of Inertiawilliamsmotowerx wrote:What is PMI?40.0 Lbs= PMI= 0.209316 Inertia HP Loss= 1.461109 @ 7000 RPM

60.0 Lbs= PMI= 0.313974 Inertia HP Loss= 2.191661

MOI is moment of inertia, right?

The above quote, are you saying there's a HP loss of 1.461109? Or gain?

And I don't know, what happened with the aluminum flywheel?

Is it correct terminology to say the crank stores energy with it's rotational inertia? There has to be an optimal weight for a given engine.