Calculating Throat Percentage

Moderator: Team

-

Frankshaft

- Guru

- Posts: 1037

- Joined: Sun Jul 05, 2015 6:01 pm

- Location:

Re: Calculating Throat Percentage

Yes, that is a lot easier. But my point was, the stem needs to be considered. Me and Zums I think were on the same page, just were thinking about it differently.

-

David Redszus

- Guru

- Posts: 9633

- Joined: Tue Nov 27, 2007 9:27 am

- Location: Chicago

- Contact:

Re: Calculating Throat Percentage

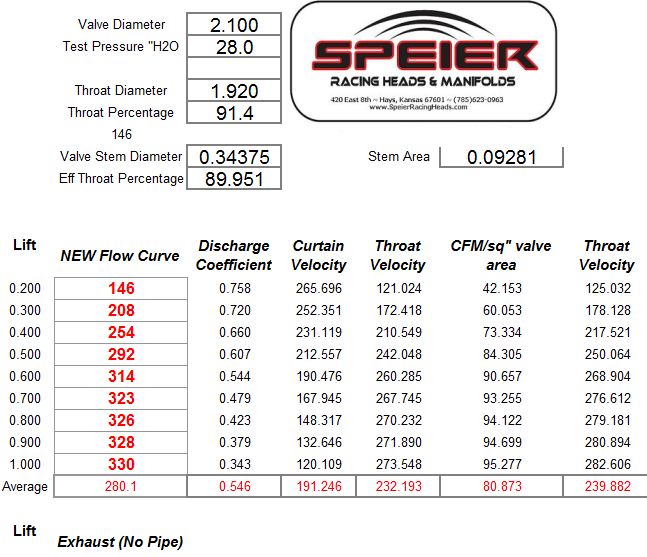

The computation chart is correct and easy. But, the valve head diameter does not reflect the flow area of the valve at all. The valve seat OD would be more accurate. However, the difference in ratio would be very small.cspeier wrote:Here is the easy way to do it!

The more important issue is "the ratio of what and for what purpose"? What purpose does knowing the ratio of diameters serve? None, really.

What is needed is an understanding of how throat to valve area will affect performance.

The port area less the valve stem area ( x flow coefficient) will determine the port limit air speed.

But the valve head area (or seat area) assumes the valve has been lifted more than 25% of head diameter.

In reality, the valve flow are is a function of valve curtain area, not head area or diameter.

Since maximum valve air flow does not occur at maximum lift or maximum curtain area, a new value must be used to determine the correct port/valve flow area ratio.

The port flow area is fixed, the valve flow area changes with lift, and the air flow itself changes with piston velocity. The task now becomes to determine what port/valve flow ratio is required at each engine rpm.

Re: Calculating Throat Percentage

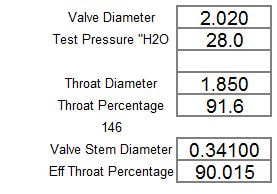

You skin the cat, i'll butcher itFrankshaft wrote:You need the throat % number to calculate the actual cross section at the throat do you not? 2.02 valve as the example, 90% throat=1.818. 1.818/2=.909

.909x.909x3.1415=2.59-.09=2.5 So, I get what your saying. But, to get a true 90%, 89% whatever your targeting, as the op asked about throat %, and how we calculate it, this is a bit more than he asked. The valve stem is in the way, and takes up space, so, the area needs to be adjusted, or, you won't have that much area. Its pretty simple. Last time I checked, the valve stem is always in the way. So, now we subtract our stem area to get the actual cross section, which I think is what you were saying zums. I was saying above, to actually be 90%, you have to add or make the area larger by the valve stem area. Follow me?

you can also bake your aluminum rods to 200 degrees and shit when you measure the clearance but normally the spec is room temp

Tom

-

user-9274568

Re: Calculating Throat Percentage

There is more on the spreadsheet and it needs valve diameter for other calculations.David Redszus wrote:The computation chart is correct and easy. But, the valve head diameter does not reflect the flow area of the valve at all. The valve seat OD would be more accurate. However, the difference in ratio would be very small.cspeier wrote:Here is the easy way to do it!

The more important issue is "the ratio of what and for what purpose"? What purpose does knowing the ratio of diameters serve? None, really.

What is needed is an understanding of how throat to valve area will affect performance.

The port area less the valve stem area ( x flow coefficient) will determine the port limit air speed.

But the valve head area (or seat area) assumes the valve has been lifted more than 25% of head diameter.

In reality, the valve flow are is a function of valve curtain area, not head area or diameter.

Since maximum valve air flow does not occur at maximum lift or maximum curtain area, a new value must be used to determine the correct port/valve flow area ratio.

The port flow area is fixed, the valve flow area changes with lift, and the air flow itself changes with piston velocity. The task now becomes to determine what port/valve flow ratio is required at each engine rpm.

Re: Calculating Throat Percentage

Yeah, what a bunch of garbagekid7755 wrote:I can't find the "Like" button.

Good stuff Chad

Heat is energy, energy is horsepower...but you gotta control the heat.

-Carl

-Carl

Re: Calculating Throat Percentage

Chad,

What effective percentage do you like to see on the intake and exhaust for racertain applications?

What effective percentage do you like to see on the intake and exhaust for racertain applications?

Re: Calculating Throat Percentage

David and Chad hit on my point.. I casually use the throat percentage numbers in conversations, but what is it we are actually discussing... what actual numbers matter and how do you arrive at them. Good stuff here.

Re: Calculating Throat Percentage

I agree a very good point brought up by David. I have read that if the percntage is too large the car won't accelerate or recover after a shift. A little expansion on this sure would help. Also how would it change for low to high port angles. I have been fiddling with a low port angle that doesn't have enough metal seemingly, on the short turn, to get to 88-90%, without having a sharp edge. What is one to do ?

-

David Redszus

- Guru

- Posts: 9633

- Joined: Tue Nov 27, 2007 9:27 am

- Location: Chicago

- Contact:

Re: Calculating Throat Percentage

The flow of air into the induction system is determined by piston velocity and ambient air pressure.

The instant piston air demand changes as a function of crank angle and engine rpm.

At lower valve lifts, the air flow is controlled by the available valve curtain area.

As engine rpm increases, and if the valve curtain area is sufficiently large, the

choke point will shift from the curtain area to the port area.

At some point, the port will not be able accommodate air flow and the rpm limit is established.

The next step is to increase the port area, to slow air velocity, and allow increased air flow at higher rpms.

But a larger port does not work well at low engine speeds; not because its choked but because it

flows too slowly.

Remember in a real engine, unlike a flow bench, we only have a limited amount of time available for

cylinder filling. Running at 6000 rpm, the entire cylinder filling process must be completed in less than

about 3ms. That's 3/1000 seconds. We need maximum air velocity;slow flowing air doesn't help much.

At low rpm, the port should be small compared to valve curtain flow area. As rpms increase, the port

should increase in size compared to valve curtain flow area.

Note that we are speaking of areas and not diameters. If we have a diameter ratio of 90%, that would

actually be an area ratio of 81%. Area ratios make it easier to perform the flow area calculations in

engine simulations.

The instant piston air demand changes as a function of crank angle and engine rpm.

At lower valve lifts, the air flow is controlled by the available valve curtain area.

As engine rpm increases, and if the valve curtain area is sufficiently large, the

choke point will shift from the curtain area to the port area.

At some point, the port will not be able accommodate air flow and the rpm limit is established.

The next step is to increase the port area, to slow air velocity, and allow increased air flow at higher rpms.

But a larger port does not work well at low engine speeds; not because its choked but because it

flows too slowly.

Remember in a real engine, unlike a flow bench, we only have a limited amount of time available for

cylinder filling. Running at 6000 rpm, the entire cylinder filling process must be completed in less than

about 3ms. That's 3/1000 seconds. We need maximum air velocity;slow flowing air doesn't help much.

At low rpm, the port should be small compared to valve curtain flow area. As rpms increase, the port

should increase in size compared to valve curtain flow area.

Note that we are speaking of areas and not diameters. If we have a diameter ratio of 90%, that would

actually be an area ratio of 81%. Area ratios make it easier to perform the flow area calculations in

engine simulations.

Re: Calculating Throat Percentage

Thanks for the explanation David, but I hate to admit I missed the point to a certain extent. If the port is sized correctly but has a large throat , the car still will not run down the track well ? Is this for any port or for more steeply down drafted ports ? Yep, as is obvious, I don't have a grip on it !