Class requires factory head & block castings, flat tappet cam & cast single carb intake, it's a lb/ci class so this will be a smaller capacity engine turning real hard.

Castings chosen are 'VT' heads - smaller chambers with a better shape than the earlier 'VN' type heads, some say there is not as much metal for porting, but from what I've seen that's not the case.

I started with a set of clean core heads, minimal core shift & clean water jackets, not previously touched & with no cracks in the chambers (hard to find!)

Valves will be 7mm stem Ti, so I've fitted .502/7mm CHE bronze guides.

Seats are 50 deg (both intake & exhaust) & sunk into the chambers a bit.

Started grinding on them today, I've done a couple of R&D ports on junk heads previously, so I got a pretty good idea where I'm headed, but I haven't had access to any junk VT castings, so I'm doing 1 cylinder 1st for testing to confirm the different chamber is going to do what I think & to trial a slightly different short turn before I commit to it.

I've got 1x intake port roughed out at the moment, here's the process:

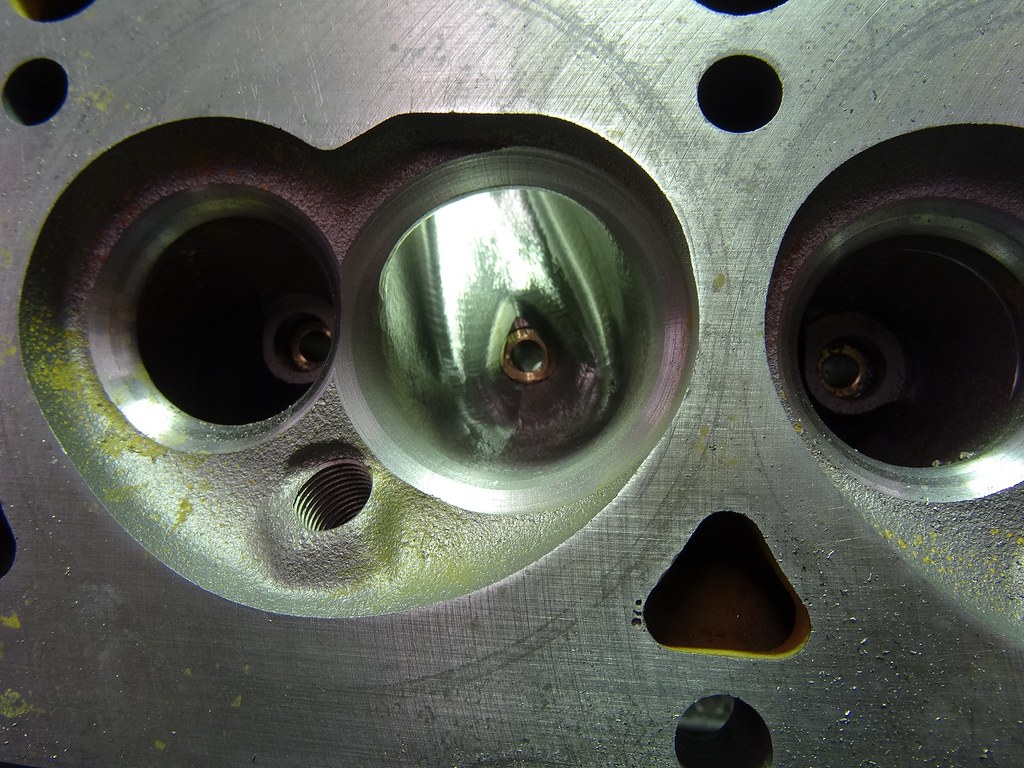

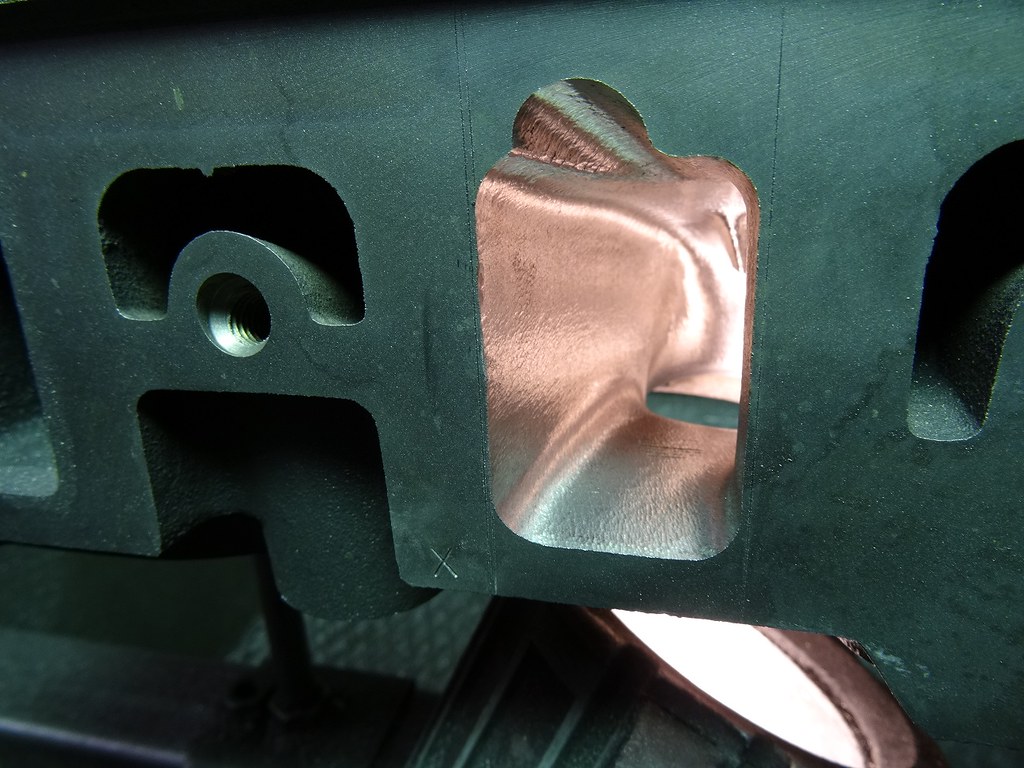

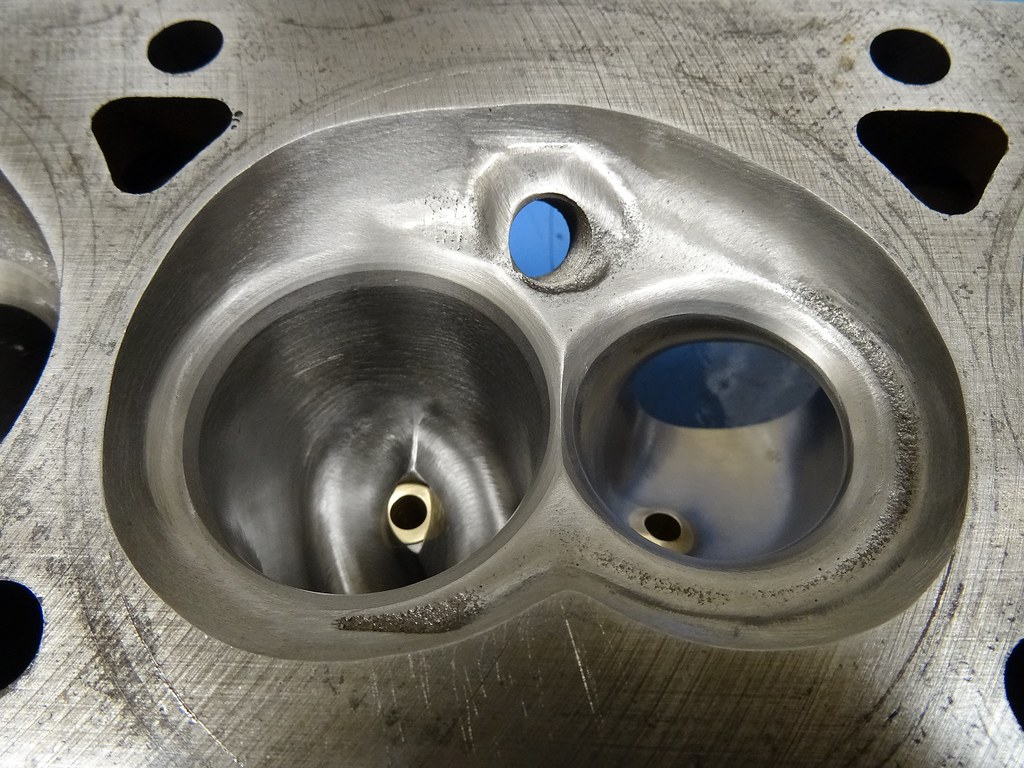

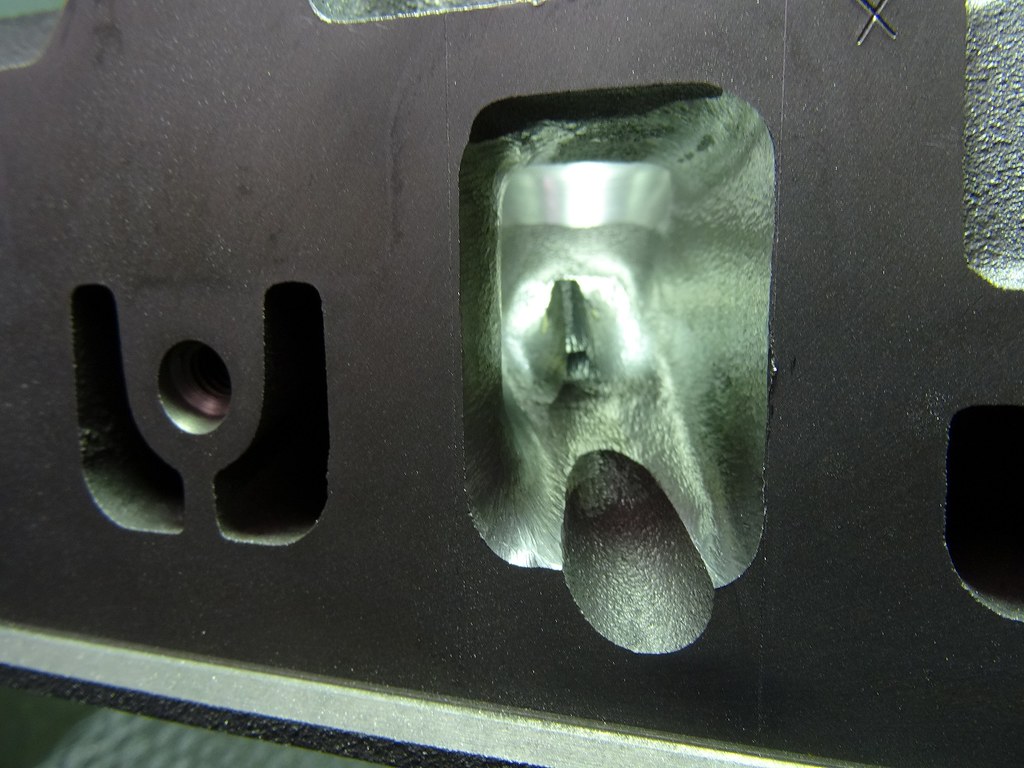

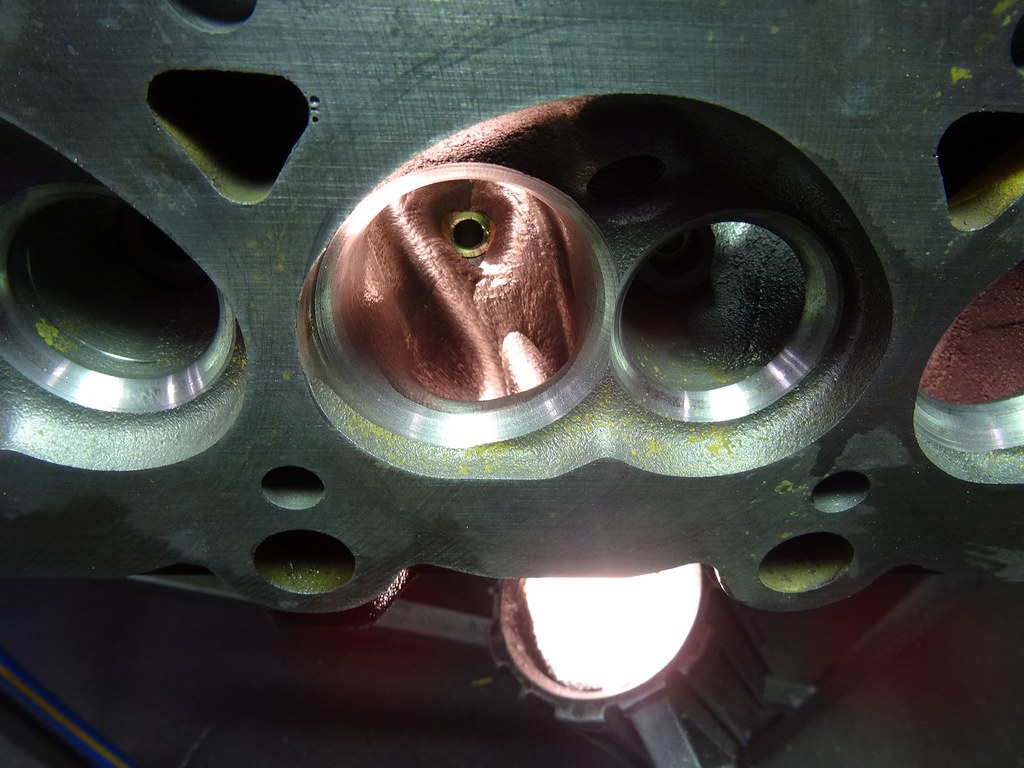

As cast with seats guides fitted & seats cut:

DSC00692 by tony knight, on Flickr

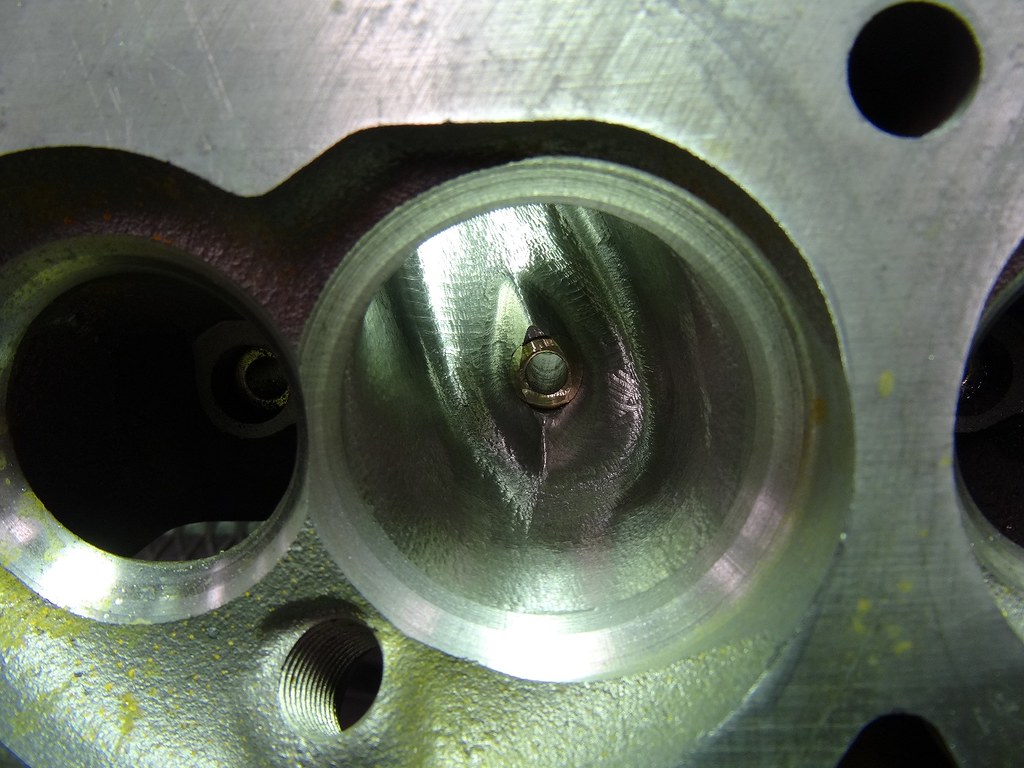

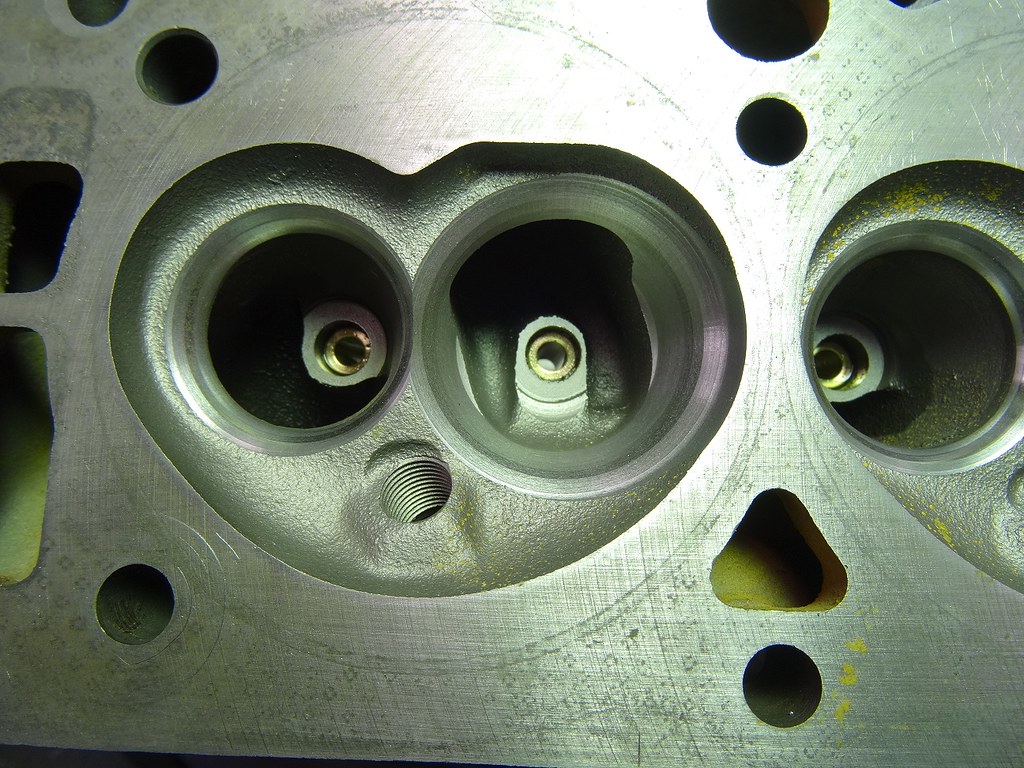

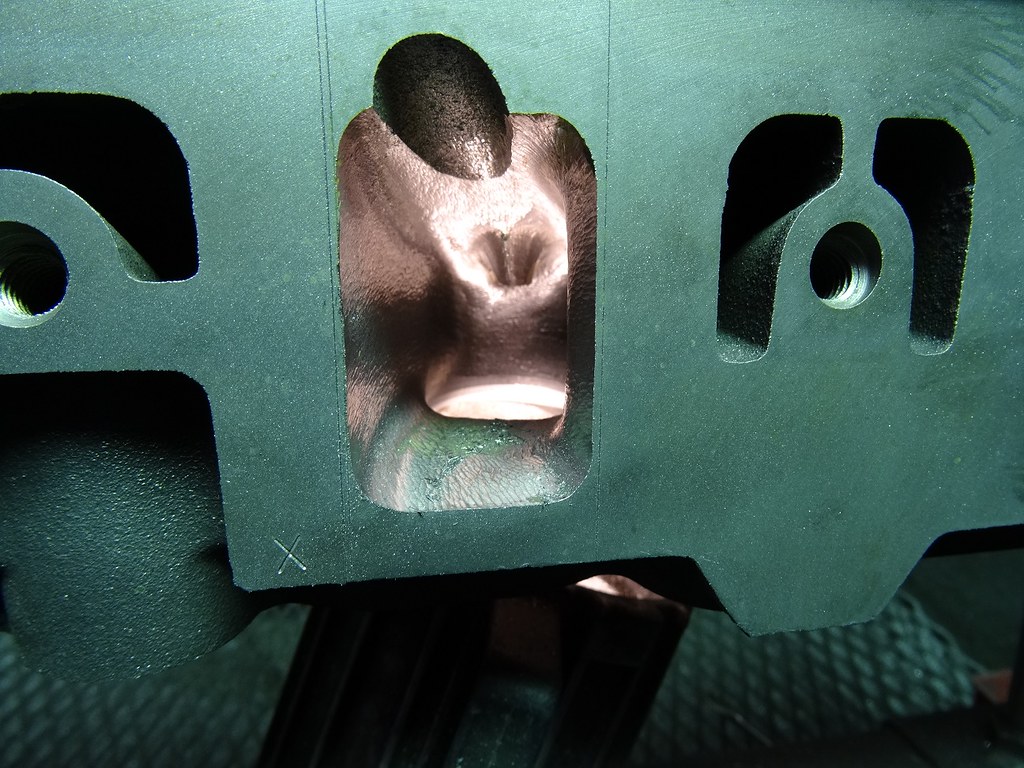

DSC00692 by tony knight, on FlickrStock runner, guide boss hacked a bit to get the bulk out the way:

DSC00693 by tony knight, on Flickr

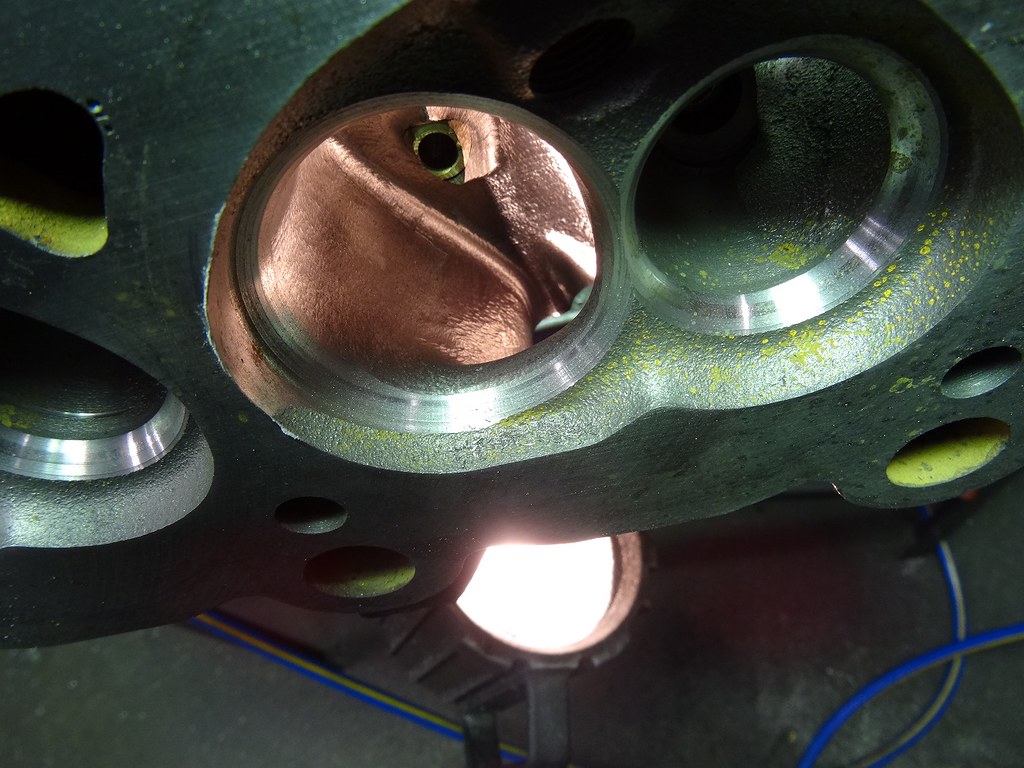

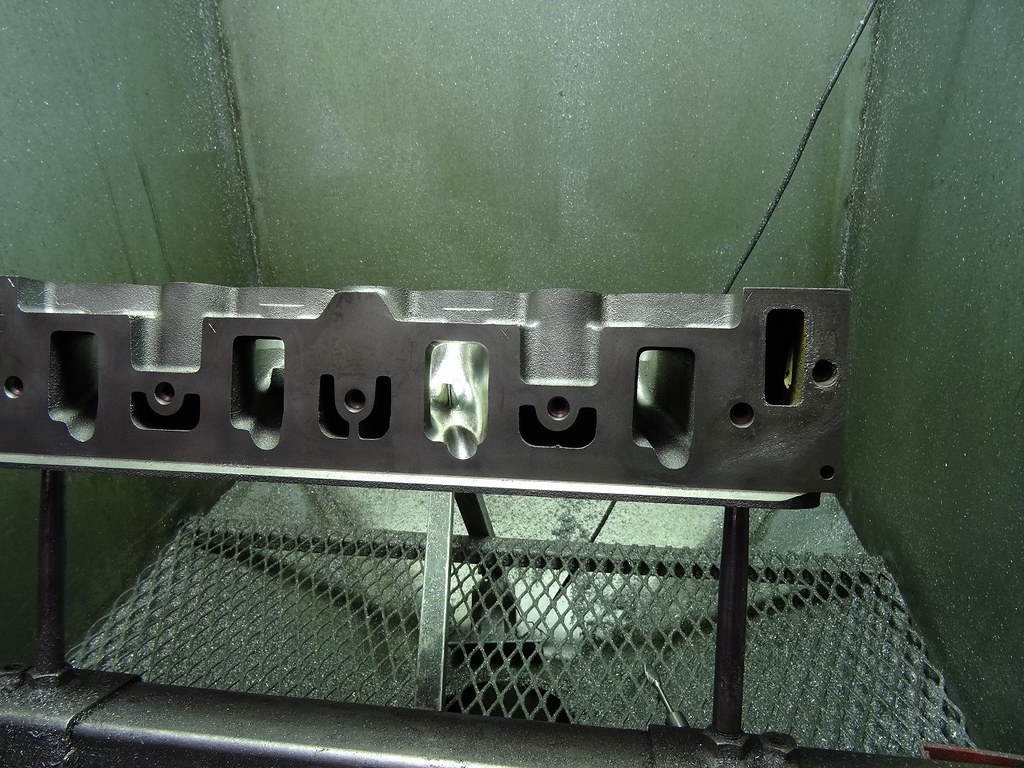

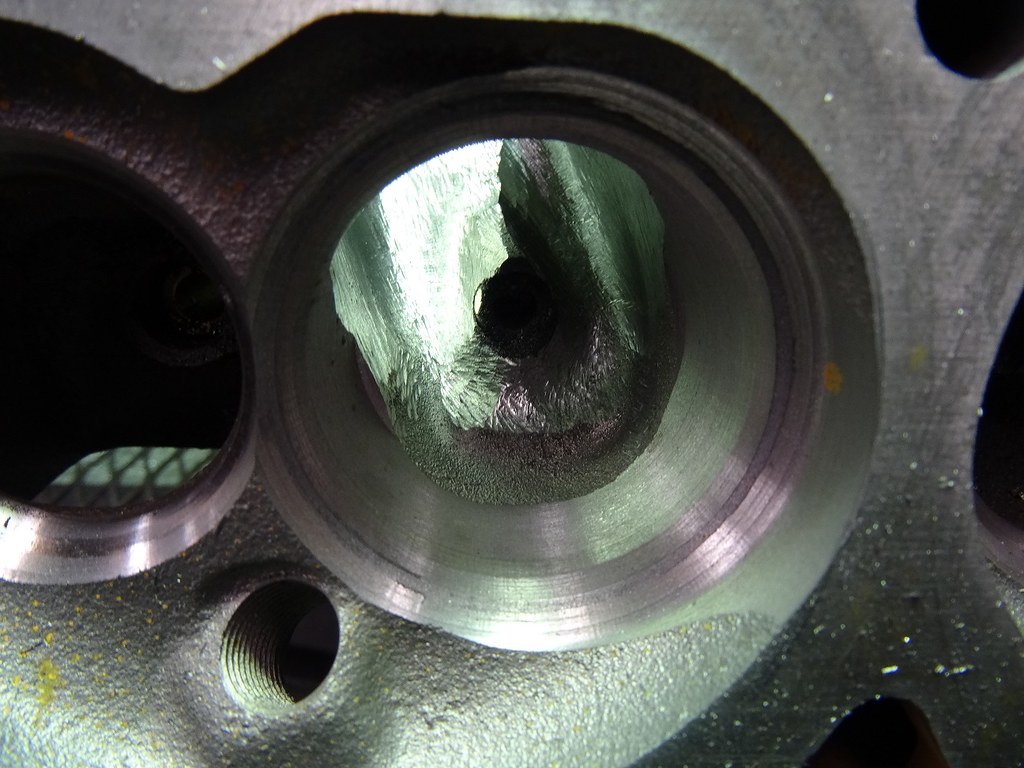

DSC00693 by tony knight, on FlickrRough sizing the walls:

DSC00694 by tony knight, on Flickr

DSC00694 by tony knight, on Flickr DSC00695 by tony knight, on Flickr

DSC00695 by tony knight, on FlickrCalipers set to stock pinch width:

DSC00696 by tony knight, on Flickr

DSC00696 by tony knight, on FlickrRoughing in the roof height:

DSC00698 by tony knight, on Flickr

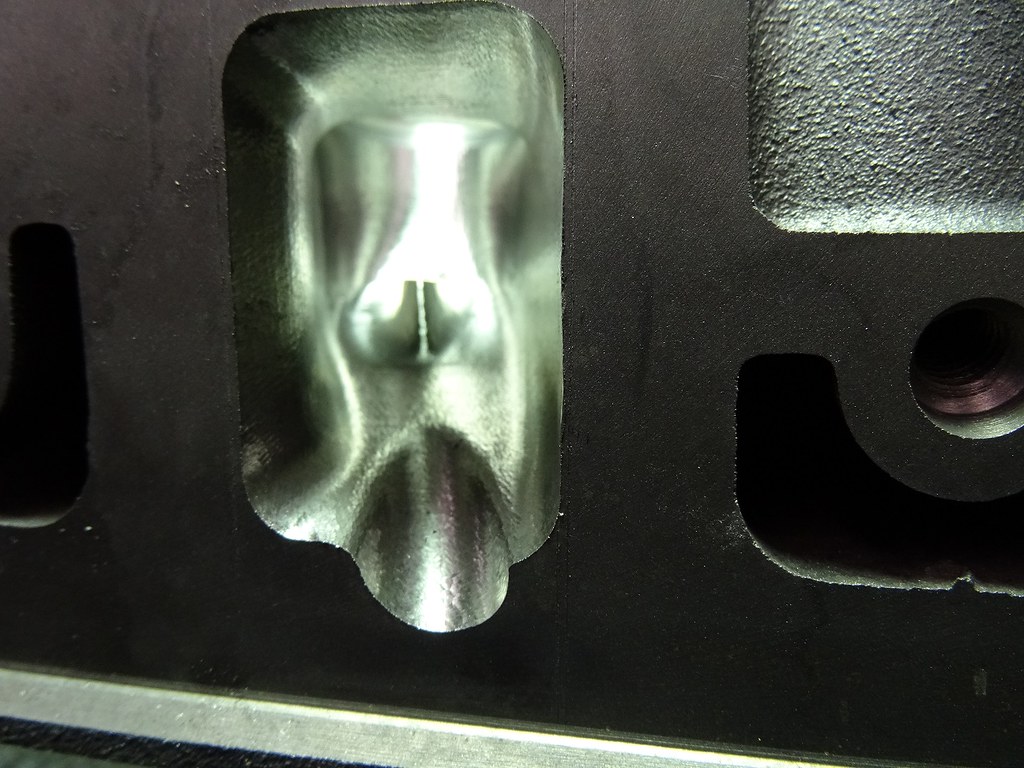

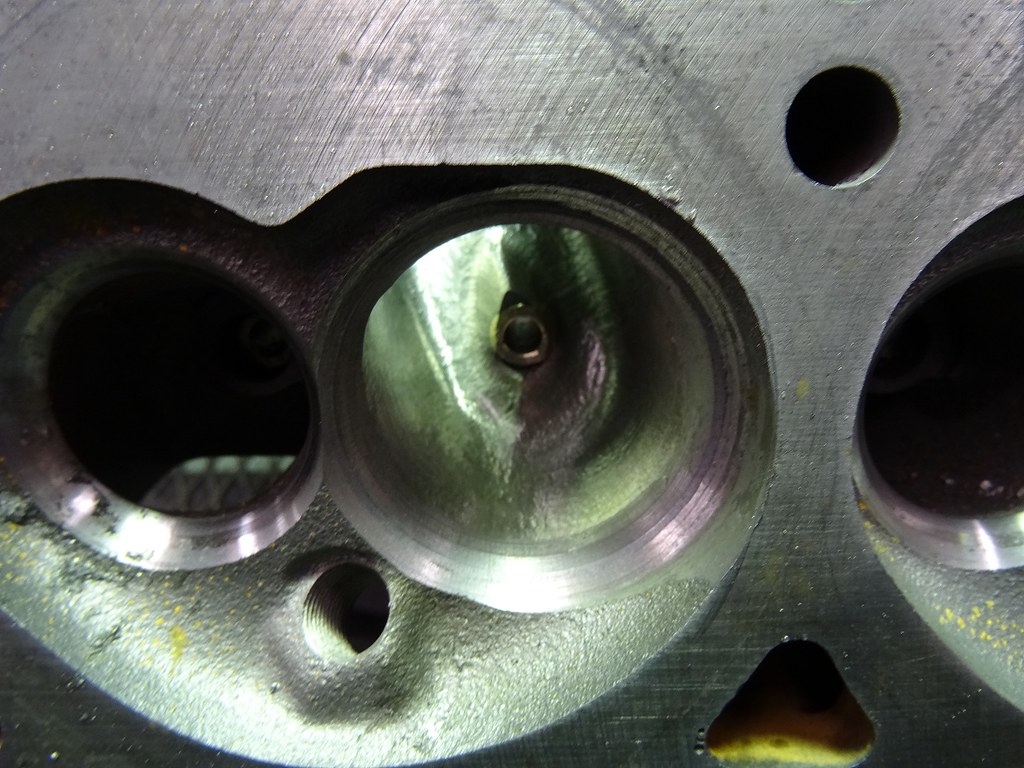

DSC00698 by tony knight, on FlickrRoughing out the bowl:

DSC00701 by tony knight, on Flickr

DSC00701 by tony knight, on Flickr DSC00703 by tony knight, on Flickr

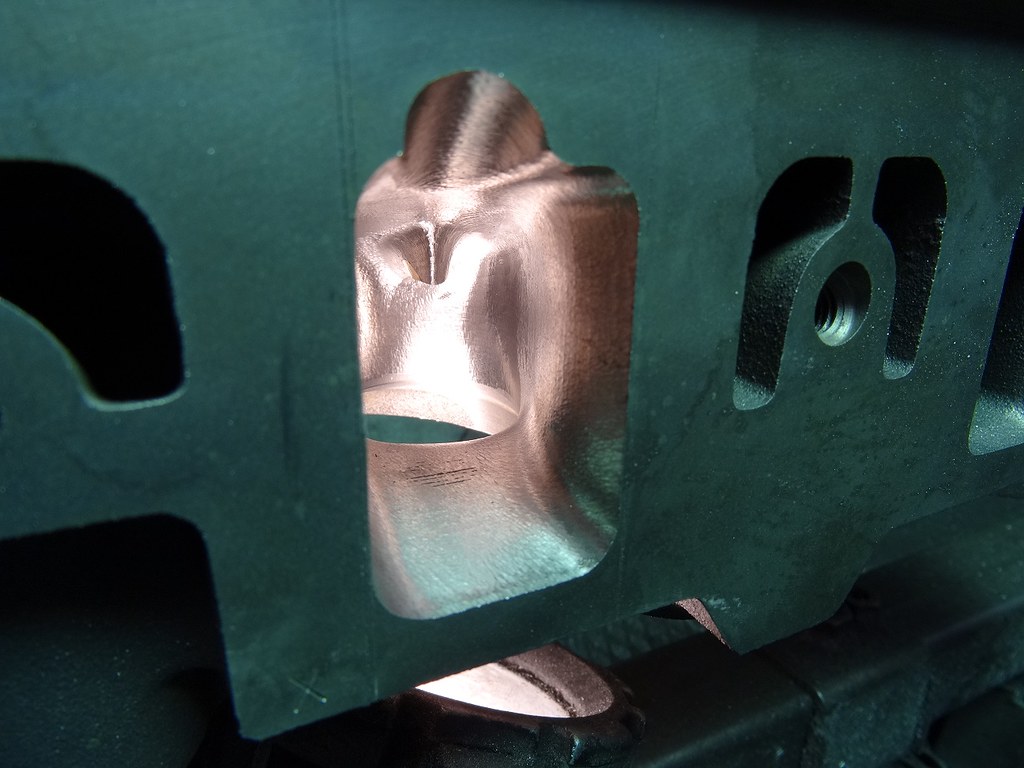

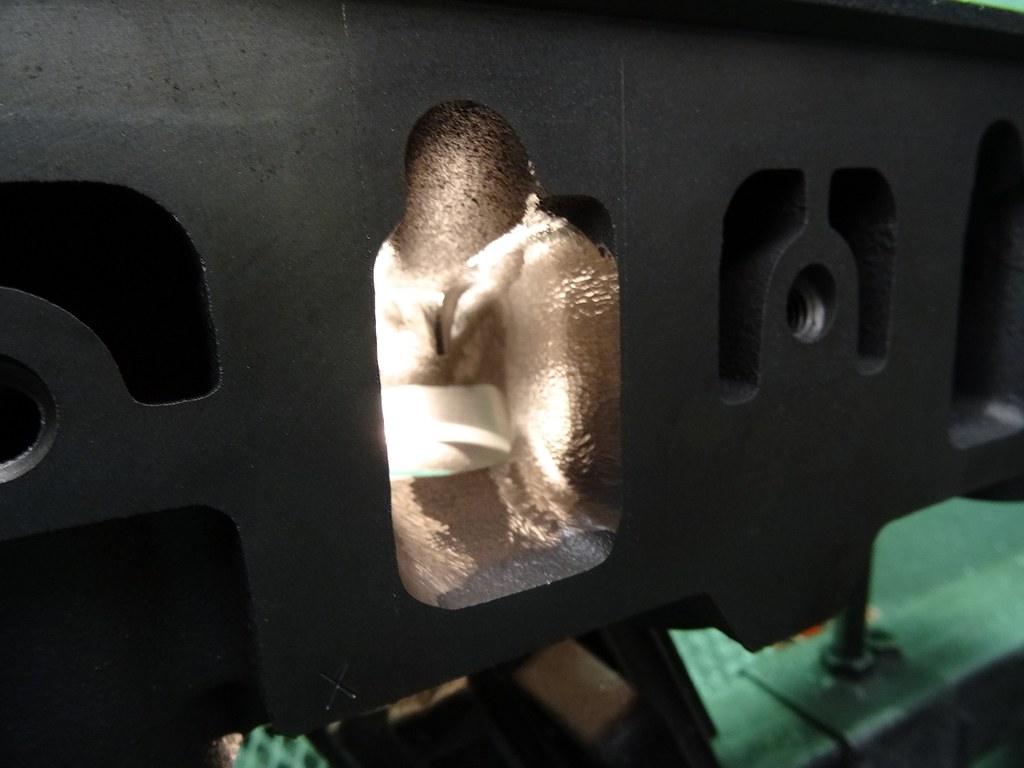

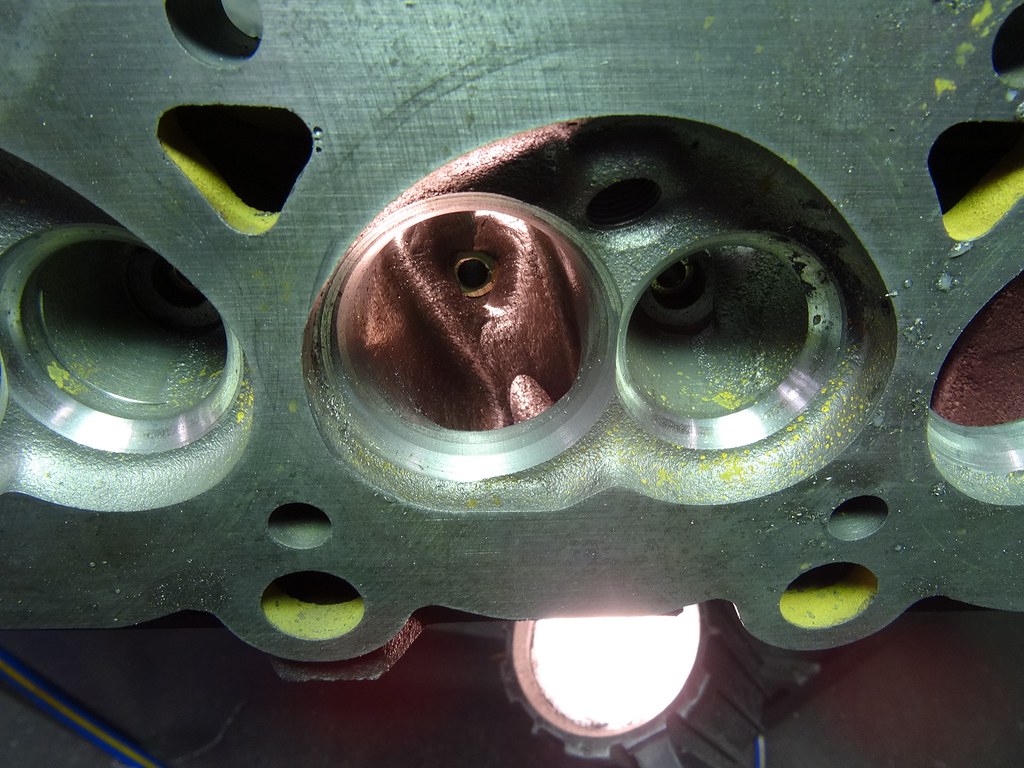

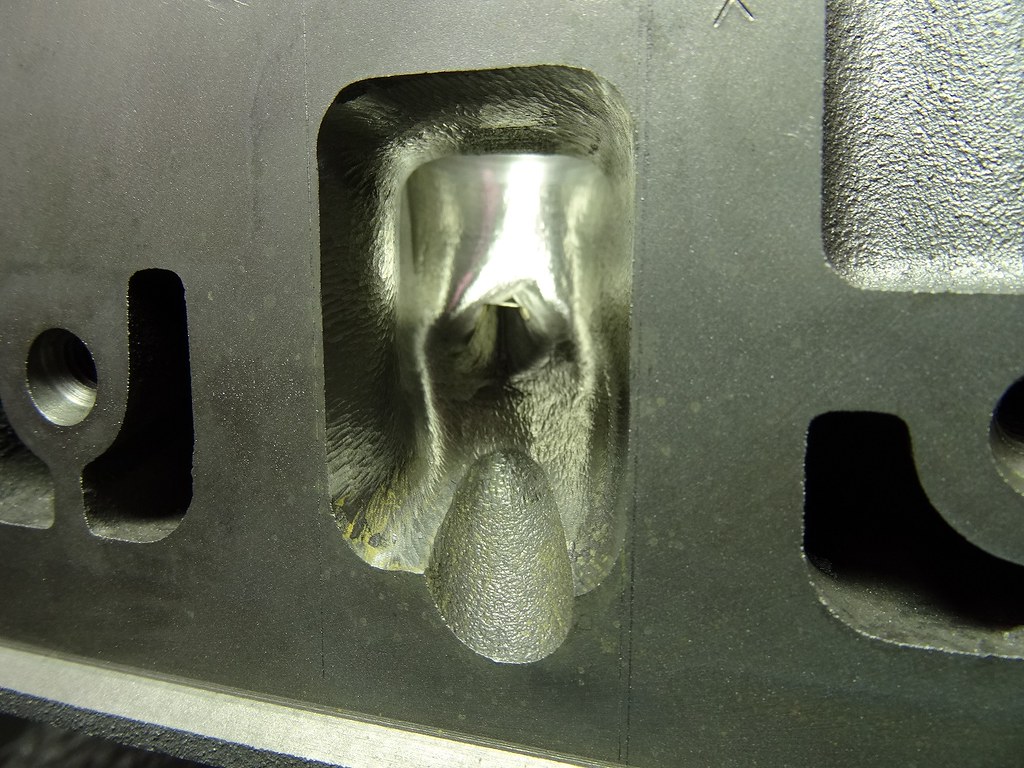

DSC00703 by tony knight, on FlickrKnocking back the short turn, not gonna be this shape, just moving metal to get the width roughly right:

DSC00704 by tony knight, on Flickr

DSC00704 by tony knight, on Flickr DSC00705 by tony knight, on Flickr

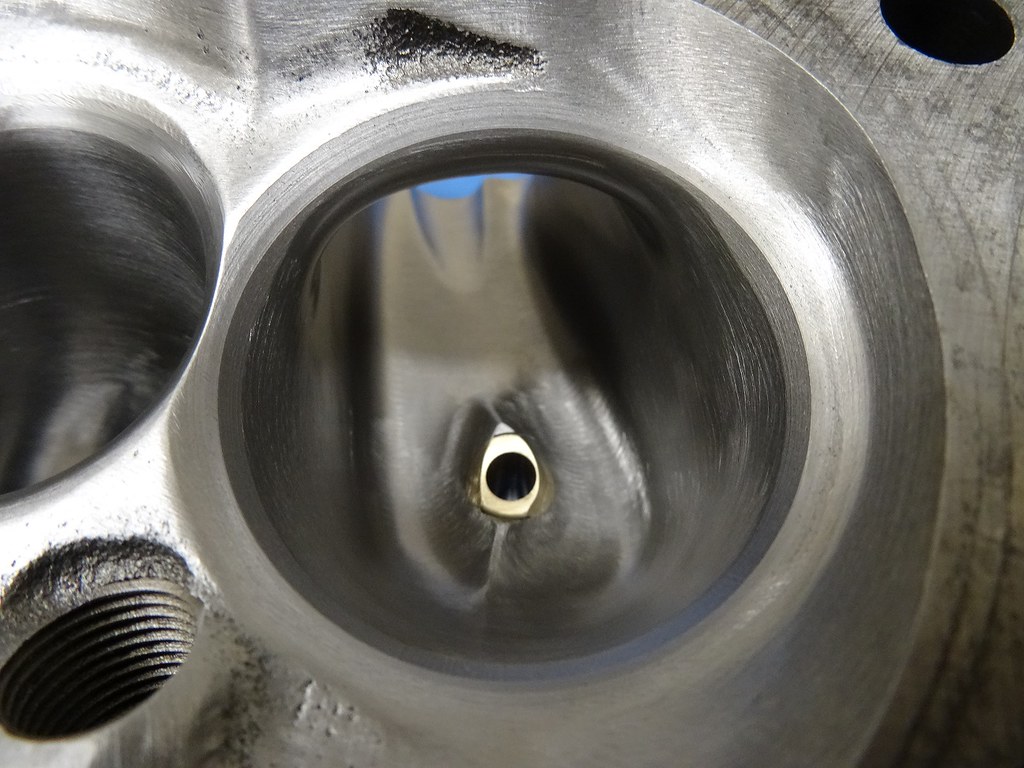

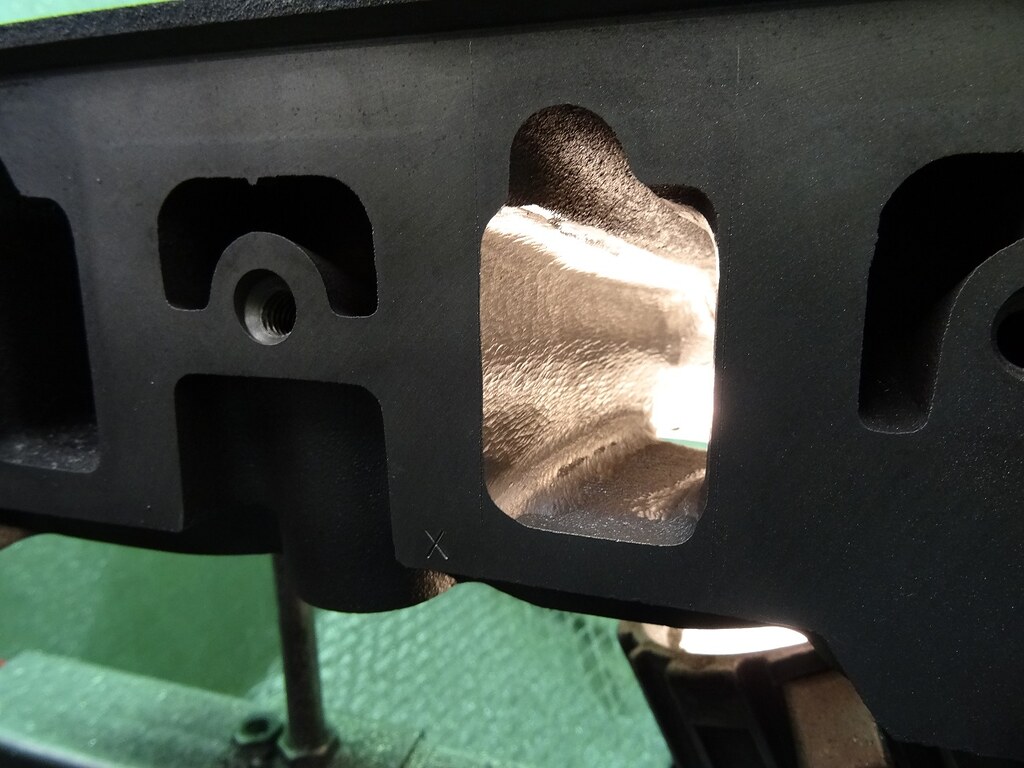

DSC00705 by tony knight, on FlickrSizing the window over the turn & the pinch:

DSC00706 by tony knight, on Flickr

DSC00706 by tony knight, on FlickrKnocking the roof into shape:

DSC00709 by tony knight, on Flickr

DSC00709 by tony knight, on Flickr DSC00710 by tony knight, on Flickr

DSC00710 by tony knight, on Flickr