REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

Moderator: Team

-

joespanova

- Expert

- Posts: 876

- Joined: Sat Dec 01, 2007 5:15 pm

- Location: McDonough Ga.

REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

I don't mess with stock type rebuilds that often .I have a SBC cast piston 5/64 5/64 3/16 older stuff.................so I get the rings ( a Sealed Power 215K or something like that )..........anyway , the top ring is only .145 ish wide , the 2nd ring is .182ish and the grooves are about .210 deep . With that much back clearance on the top ring............I was concerned. The top ring is a steel moly filled ring..........2nd is plain cast.

There was apparently a design change to the top ring in cheapo' sets. As far as I know all manufacturers have gone this route. Anyone have experience and an opinion?

There was apparently a design change to the top ring in cheapo' sets. As far as I know all manufacturers have gone this route. Anyone have experience and an opinion?

modified wanna be

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

You can buy shimstock from total seal to fill up the excess back clearance if you're worried.

Carlquist Competition Engines

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

Use TS shim stock and the ring needs to be flush or recessed when all is done.

NHRA SS/G

1970 AMC AMX - 390 4-speed

Advanced Clutches - Red Line Racing Cams

1970 AMC AMX - 390 4-speed

Advanced Clutches - Red Line Racing Cams

-

piston guy

- Guru

- Posts: 1029

- Joined: Mon Sep 10, 2012 1:55 pm

- Location: Anaheim, CA

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

joespanova,

I would be concerned too. not with the ring because the steel material has to have less radial width to maintain the same tension on the cylinder wall. BUT the extra back clearance in the top ring groove makes the ring less reactive to combustion pressure as you noted. I would certainly use the shim stock already mentioned to reduce that back clearance to .010. You could check this after the shim stock is installed , making sure the ring is .010-.020 below the ring land area. ( to allow for expansion). You do not want the ring to be above the aluminum of the piston.

This is the same recommendation Jeff Lee and Bill C already gave you.

I would be concerned too. not with the ring because the steel material has to have less radial width to maintain the same tension on the cylinder wall. BUT the extra back clearance in the top ring groove makes the ring less reactive to combustion pressure as you noted. I would certainly use the shim stock already mentioned to reduce that back clearance to .010. You could check this after the shim stock is installed , making sure the ring is .010-.020 below the ring land area. ( to allow for expansion). You do not want the ring to be above the aluminum of the piston.

This is the same recommendation Jeff Lee and Bill C already gave you.

-

DaveMcLain

- Guru

- Posts: 2858

- Joined: Thu Jan 06, 2011 8:57 am

- Location:

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

Hastings has been doing that on their stock rebuilder ring set. I called and asked about it the first time I saw that about a year or so ago because I thought that the rings might have been packaged wrong. I was assured that it was a design change. That engine(351 Windsor) sealed up and ran just fine when I dyno tested it and in the car all is well.

I've put together several engines like that now with no problems.

I've put together several engines like that now with no problems.

-

Steve Haaf

- Member

- Posts: 119

- Joined: Wed Feb 18, 2015 10:42 pm

- Location:

-

ProPower engines

- Guru

- Posts: 8707

- Joined: Sun Jan 21, 2007 1:16 pm

- Location: Victoria BC Canada

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

The ring makers have switched manufacturing methods on some common rings. Mostly top rings are now being made from tube which is easy to part off single rings for finishing.

The shim stock is available in a few different thickness's if you want the ultimate fit but it just means for those that were using it before they now need a wider selection of shim material

The shim stock is available in a few different thickness's if you want the ultimate fit but it just means for those that were using it before they now need a wider selection of shim material

Real Race Cars Don't Have Doors

-

DaveMcLain

- Guru

- Posts: 2858

- Joined: Thu Jan 06, 2011 8:57 am

- Location:

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

No, I used the rings just as they came out of the package. I checked the end gap and put them on the pistons. They worked fine nothing very high powered mostly stock street stuff and a boat or two but right now I'm getting ready to dyno test a 383 Chevy build that's put together using a KB Icon piston and that same ring set. We'll see what happens. It is nothing fancy, EQ heads, Scat rods and crank, Perf RPM and a hydraulic roller. I'd like to see it peak at about 5-5200rpm for a jet boat application.Steve Haaf wrote:Dave, did you use the shim stock on your rebuilds?

-

DaveMcLain

- Guru

- Posts: 2858

- Joined: Thu Jan 06, 2011 8:57 am

- Location:

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

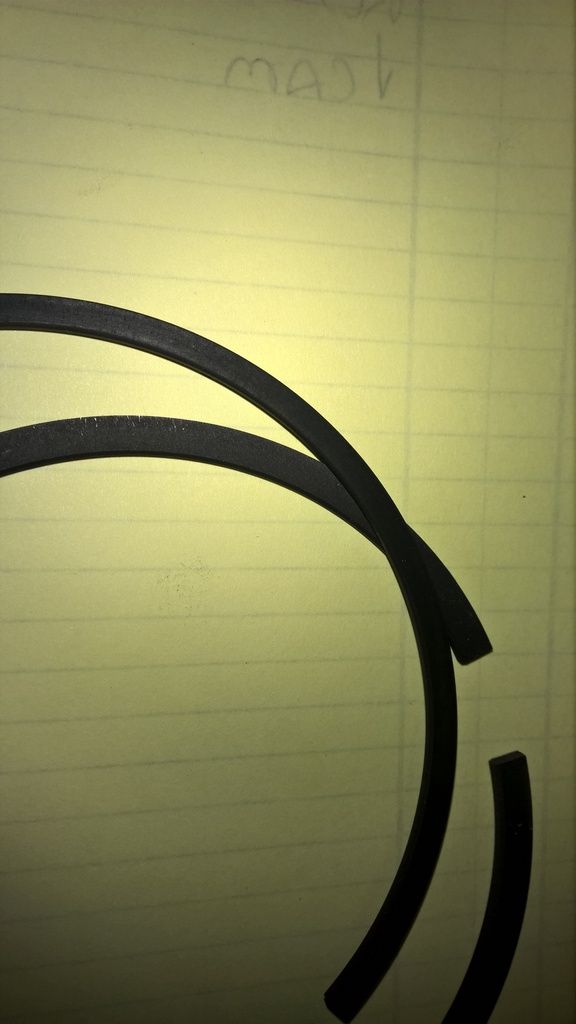

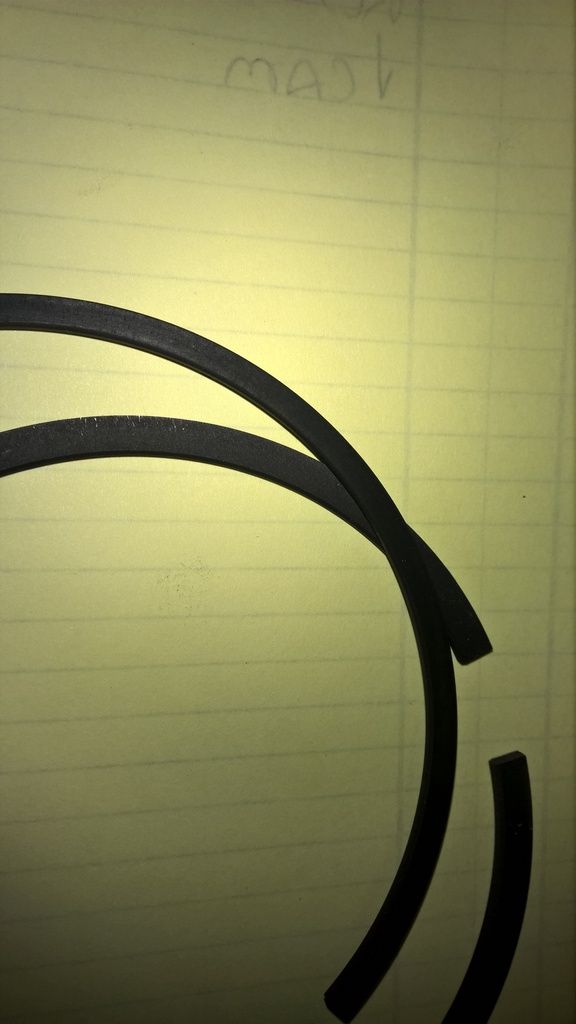

I just thought about it and I had a set of these rings here at the shop that are going into a stock 351 Cleveland repair build. This stuff is tough to photograph but you get the idea. The moly faced top ring is the one with less radial thickness..

My thoughts were that it seems like it would "slow down" the response that the top ring has to cylinder pressure changes but since the engine speed is so low it probably doesn't really suffer in that regard and it has less tension/friction when running. Also since the ring is thinner and lighter maybe that helps a bit too. Thinking back a month or two ago I had a Chevy 350 freshen up that I ran on the dyno. It had a simple glaze break done to the cylinders and it had this same ring set. It sealed right up and I didn't see any significant blow by after the warm up period say 30 minutes or so of run time.

My thoughts were that it seems like it would "slow down" the response that the top ring has to cylinder pressure changes but since the engine speed is so low it probably doesn't really suffer in that regard and it has less tension/friction when running. Also since the ring is thinner and lighter maybe that helps a bit too. Thinking back a month or two ago I had a Chevy 350 freshen up that I ran on the dyno. It had a simple glaze break done to the cylinders and it had this same ring set. It sealed right up and I didn't see any significant blow by after the warm up period say 30 minutes or so of run time.

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

No worries, new and improved (and cheaper for them to make.)

The SAE has forever had specifications for ring radial depth and identified them by letter code. Somewhat on the same subject, the Packard V8 uses an SAE K-wall ring of .200" depth. Egge Machine repop pistons are cut with the Ford/Chevy D-wall depth of .185", so an OEM Packard ring set can't be used in the repop piston because it will bottom in the ring grooves, but shallower Ford/Chevy rings work just fine in the deeper grooves of the OEM Packard pistons.

When they first began shipping these without any explanatory paperwork, the phones were ringing all day at Enginetech, Hastings, Grant, et al. As did you, everyone thought he was getting mispackaged rings.Hastings has been doing that on their stock rebuilder ring set. I called and asked about it the first time I saw that about a year or so ago because I thought that the rings might have been packaged wrong. I was assured that it was a design change.

The SAE has forever had specifications for ring radial depth and identified them by letter code. Somewhat on the same subject, the Packard V8 uses an SAE K-wall ring of .200" depth. Egge Machine repop pistons are cut with the Ford/Chevy D-wall depth of .185", so an OEM Packard ring set can't be used in the repop piston because it will bottom in the ring grooves, but shallower Ford/Chevy rings work just fine in the deeper grooves of the OEM Packard pistons.

Jack Vines

Studebaker-Packard V8 Limited

Obsolete Engineering

Studebaker-Packard V8 Limited

Obsolete Engineering

-

bigjoe1

- Show Guest

- Posts: 6199

- Joined: Thu Aug 24, 2006 8:16 pm

- Location: santa ana calif-92703

- Contact:

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

I like the idea of less ring tension if there are no negative affects.

JOE SHERMAN RACING

JOE SHERMAN RACING

-

joespanova

- Expert

- Posts: 876

- Joined: Sat Dec 01, 2007 5:15 pm

- Location: McDonough Ga.

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

OK

Thanks guys for the "heads up". For this build they run as is with no shims / spacers . I understand and appreciate the suggestion about spacers........but lets try it without and see how it runs.

Thanks guys for the "heads up". For this build they run as is with no shims / spacers . I understand and appreciate the suggestion about spacers........but lets try it without and see how it runs.

modified wanna be

-

engineguyBill

- Guru

- Posts: 1264

- Joined: Fri Feb 26, 2010 11:15 am

- Location: Gold Canyon, AZ

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

For many years American automobile manufacturers used "SAE D-wall" specification for radial thickness of compression rings. D-wall is the cylinder bore divided by 22, which equals .182" for a 4.000" bore. In recent years the ring widths have been reduced significantly (1.2mm, 1.5mm etc) and radial thickness is also reduced. There are some OEM engines currently produced with 0.80mm top ring and 1.5mm oil rings! Most current top rings are manufactured from stainless steel (alloy steel with at least 10.5% Chromium (Cr). This steel comes in wire form and is delivered in large spools. Second rings may be made from either steel, ductile iron or grey iron and are typically a Napier-style design. When using the wire type rings, there is significantly less machining necessary, as compared to a cast ring made with ductile or cast iron. Coatings have been modernized as well, gas-nitrided and PVD coatings have made the old ductile iron, plasma Moly sprayed top ring pretty much outdated now. DLC is also used with some steel compression rings, however it is very expensive and the results are not worth the cost involved - at this time.

Bill

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

Perfect Circle Doctor of Motors certification

SAE Member (30 years)

ASE Master Certified Engine Machinist (+ two otherASE Master Certifications)

AERA Certified Professional Engine Machinist

-

joespanova

- Expert

- Posts: 876

- Joined: Sat Dec 01, 2007 5:15 pm

- Location: McDonough Ga.

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

Thanks for that info..........interesting.

modified wanna be

Re: REDUCED RING RADIAL WIDTHS IN CHEAP BUILDS

It certainly used to be accepted theory that minimizing back clearance would improve ring response and sealing. However when I discussed it with Total Seal a year or so back, they didn't seem too concerned about it. (Maybe this was just in regards to my street/strip TRW-piston BBC with 1/16" rings)

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.