True, at this point it's not 'for sure' but it would be easy enough to check actual coil bind height and if the math doesn't add up to allow significant retainer/seal interference, I don't see what other conclusion is possible.RW TECH wrote:How can you know for sure?MadBill wrote:Still, the retainer would have to do more than just touch the seal to crush it, say at least another 1/16". Combined with the fact that two were undamaged, assembly error looks to me like the most likely cause.

It's more than a coincidence that absolutely none of the intakes fell apart but 75% of the exhausts did.

Valve stem seals crushed, LS7. More spring?

Moderator: Team

Re: Valve stem seals crushed, LS7. More spring?

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

Re: Valve stem seals crushed, LS7. More spring?

The only problem is sometimes the stem gyrates enough to make most people say "wow", and the retainer is keeping step with it plus a little freedom of linear movement while the center of the spring is trying to make it's mind up where it wants to go.MadBill wrote:

Yes, I guess if it was that simple it would already be standard practice. If it hasn't already been tried though, setting up to compare retainer vs. valve center motion might point to a perhaps less accurate but more versatile arrangement.

-

allencr267

- Pro

- Posts: 364

- Joined: Wed Nov 07, 2012 6:28 pm

- Location: Tallahassee Florida USofA

Re: Valve stem seals crushed, LS7. More spring?

Isn't it easy enough to do with a manual/lever action, let alone a pneumatic spring compressor?

MadBill wrote:... assembly error looks to me like the most likely cause.

-

pamotorman

- Guru

- Posts: 2802

- Joined: Thu Mar 06, 2014 11:55 pm

- Location:

Re: Valve stem seals crushed, LS7. More spring?

how about the possibility the seal moved on the guide when it stuck to a hot valve stem. I never used a positive seal on the exhaust side of any race engine and always used a umbrella type because the exhaust guide need some lubricationMadBill wrote:Still, the retainer would have to do more than just touch the seal to crush it, say at least another 1/16". Combined with the fact that two were undamaged, assembly error looks to me like the most likely cause.

Re: Valve stem seals crushed, LS7. More spring?

I removed the springs and used a jewellers file on the seal ID to make reliefs for increased oil metering.

I'll check actual coil bind tomorrow. Should have my new bench tester tomorrow, if the brown truck shows up.

I'll check actual coil bind tomorrow. Should have my new bench tester tomorrow, if the brown truck shows up.

Re: Valve stem seals crushed, LS7. More spring?

Good point. A lot of us have seen those slo-mo clips that show the stems waving like daisies in a breeze...RW TECH wrote:The only problem is sometimes the stem gyrates enough to make most people say "wow", and the retainer is keeping step with it plus a little freedom of linear movement while the center of the spring is trying to make it's mind up where it wants to go.MadBill wrote:

Yes, I guess if it was that simple it would already be standard practice. If it hasn't already been tried though, setting up to compare retainer vs. valve center motion might point to a perhaps less accurate but more versatile arrangement.

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

-

Kevin Johnson

- HotPass

- Posts: 9392

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Valve stem seals crushed, LS7. More spring?

A possibility:

The use of a roller rocker on heavier-than-stock hollow stem exhaust valves possibly near valve float conditions could give rise to magnified/oscillating side loading forces that would work the seals loose and allow them to travel up the guide to subsequently be crushed.

GM could have used roller rockers but chose coined cycloidal contact pads instead.

The use of a roller rocker on heavier-than-stock hollow stem exhaust valves possibly near valve float conditions could give rise to magnified/oscillating side loading forces that would work the seals loose and allow them to travel up the guide to subsequently be crushed.

GM could have used roller rockers but chose coined cycloidal contact pads instead.

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

Re: Valve stem seals crushed, LS7. More spring?

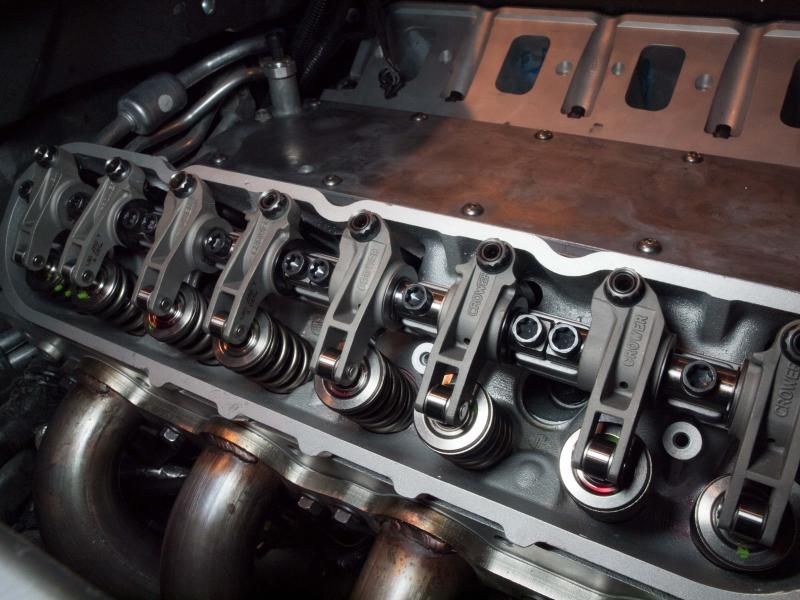

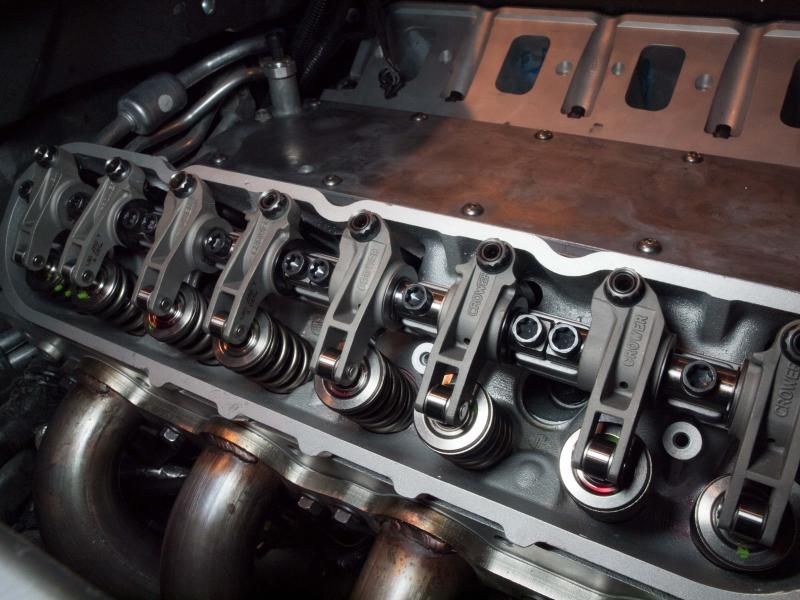

The contact was about as good as one could expect. Here are a couple pics after full engine rotation with hydraulic lifters modified to act as solid lifters.

Re: Valve stem seals crushed, LS7. More spring?

Thanks Kevin nice pics- reference the stock rocker for a minuie

Let me recap (maybe wrongly) from a couple of threads

One has the stock rockers with above .630 lift showing problem with running off the inside of the valve tips causing several different problems/ wear

This is what happens when you add lift and it's all moving the tip down from the stock location

a fix for moderate lift increases is to change to a longer valve or add lash caps

stock the rocker angles up when on the seat and down a certain angle down at max lift

you make the rocker angle more up on the seat and less down at max lift (with the additional lift)

+100 valves work well with +200 lift from stock- but check the location of the contact at top, mid bottom

want to lessen the angle- backset the studs or backset trunions - the fulcurm with longer arms-- also gives more pushrod clerance

am I missing something?

been doing this for years- why the problems on the LS?

Did they make changes on the COPO that would help? (IDK)

also some cut the spring seats and go to BBC size springs- Why not?

Doing that with SBC for years eventhough it requires special head bolts or studs/ nuts are there special challenges with the LS?

I don't want to get into half lift or other long held theories on rocker geometry

I've used 1/3 and I have had the tangent down near full lift trying to get more lift and getting lots of valve heave

I'd go with whatever the camgrinder recommends but it is clear from several major camgrinders literature that they do not understand rocker arm geometry and give very bad advice (or did) and most have "moved on"

just trying to encapsulate the discussion

Happy New Year

Let me recap (maybe wrongly) from a couple of threads

One has the stock rockers with above .630 lift showing problem with running off the inside of the valve tips causing several different problems/ wear

This is what happens when you add lift and it's all moving the tip down from the stock location

a fix for moderate lift increases is to change to a longer valve or add lash caps

stock the rocker angles up when on the seat and down a certain angle down at max lift

you make the rocker angle more up on the seat and less down at max lift (with the additional lift)

+100 valves work well with +200 lift from stock- but check the location of the contact at top, mid bottom

want to lessen the angle- backset the studs or backset trunions - the fulcurm with longer arms-- also gives more pushrod clerance

am I missing something?

been doing this for years- why the problems on the LS?

Did they make changes on the COPO that would help? (IDK)

also some cut the spring seats and go to BBC size springs- Why not?

Doing that with SBC for years eventhough it requires special head bolts or studs/ nuts are there special challenges with the LS?

I don't want to get into half lift or other long held theories on rocker geometry

I've used 1/3 and I have had the tangent down near full lift trying to get more lift and getting lots of valve heave

I'd go with whatever the camgrinder recommends but it is clear from several major camgrinders literature that they do not understand rocker arm geometry and give very bad advice (or did) and most have "moved on"

just trying to encapsulate the discussion

Happy New Year

-

Kevin Johnson

- HotPass

- Posts: 9392

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Valve stem seals crushed, LS7. More spring?

How about converting a suitable roller rocker to instead mount an extended cycloidal curve pad.

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

-

pamotorman

- Guru

- Posts: 2802

- Joined: Thu Mar 06, 2014 11:55 pm

- Location:

Re: Valve stem seals crushed, LS7. More spring?

what about "valve toss" that allows more lift than the cam specs show

Re: Valve stem seals crushed, LS7. More spring?

I have seen quite a few spintron videos with valve trains and valve springs with high rpm crazy bad oscillations and convulsions where the valve spring bottom and spring base was actually jumping up.

Could this occur to the point where it actually lifted the valve seal or loosened it off the stem and started its destruction? Just another thought here.

Could this occur to the point where it actually lifted the valve seal or loosened it off the stem and started its destruction? Just another thought here.

The Older I Get, The Dumber I Get

-

Kevin Johnson

- HotPass

- Posts: 9392

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Valve stem seals crushed, LS7. More spring?

https://www.youtube.com/watch?v=C1aSBeCFPzk Wilberforce pendulum https://en.wikipedia.org/wiki/Wilberforce_pendulum gives you an idea of the degrees of freedom of movement of an oscillating mass. Consider that the valve stem is also an excited torsion spring.Newold1 wrote:I have seen quite a few spintron videos with valve trains and valve springs with high rpm crazy bad oscillations and convulsions where the valve spring bottom and spring base was actually jumping up.

Could this occur to the point where it actually lifted the valve seal or loosened it off the stem and started its destruction? Just another thought here.

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

Re: Valve stem seals crushed, LS7. More spring?

The COPO has 100% of the stuff I've mentioned in earlier posts, including the stock guides, rockers, pushrods (some packages), valves, retainers, & locks.wyrmrider wrote: Did they make changes on the COPO that would help? (IDK)

What it had going for itself is someone must have been paying attention to make sure the valvetrain wasn't going to throw up all over itself at above 8K RPM with all those "stockish" parts.

Re: Valve stem seals crushed, LS7. More spring?

Wouldn't rule it out, especially with some of the lobe designs that are floating around out there (no pun intended).pamotorman wrote:what about "valve toss" that allows more lift than the cam specs show