Push rod

Moderator: Team

Re: Push rod

Manton is an excellent company to deal with and they make an excellent product but as noted above they are not cheap. Have run 7/16 pushrods since 2007 in a sbc chevy with no problems. The rocker arm is 1.9 on SB2.2 heads and runs 7.5's in a 1850 lb dragster.

John

John

Re: Push rod

Bigger pushrods ARE way overrated in typical SBC with 23* heads.Warp Speed wrote:bigjoe1 wrote:Bigger diameter push rods are WAY OVER RATED

JOE SHERMAN RACING

There are all kinds of idiots blabbering stuff about pushrod size and open spring loads (pressure if you like) on the internet.

That would be the first clue they have no idea what they are talking about. Spring mass and seat loads would be the spring’s part in pushrod deflection at max valve acceleration. Open don’t matter.

Some of them seem to think a 7000 rpm SBC needs bigger pushrods or it will self-destruct. Too funny.

I believe there are engines that desperately need big pushrods. Anyone who has hammered a nail into a board wrong should be able to figure that one out.

I also have a 9000 RPM 357 SBC with Jesel shaft rockers (no studs) that has had both 5/16" and 3/8" pushrods in it.

"I promise you Sheriff, I won't throw one more rock... Didn't say nothin' 'bout no brick!" --Ernest T Bass

Re: Push rod

Thanks Joe... (I think)

Hey Sanford and son:

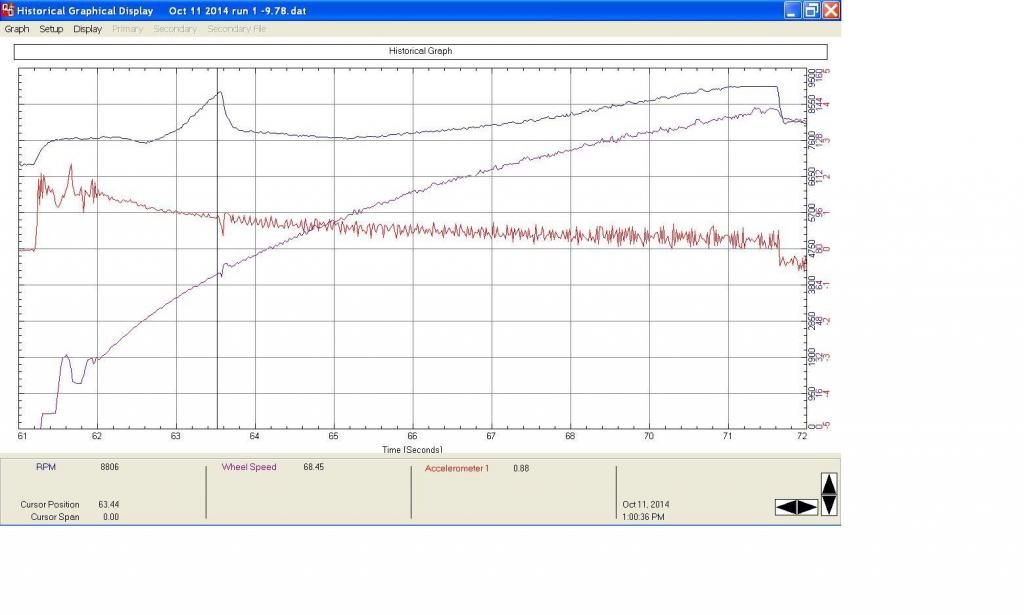

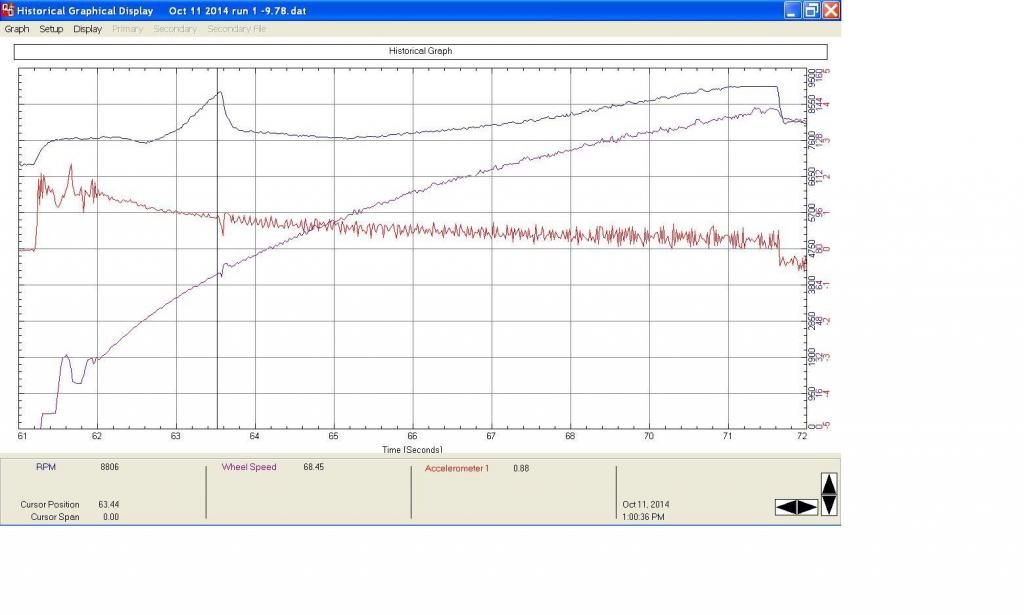

Some people just talk RPM .....I record it. 9200 rpm on this pass Oct 11 2014. The data recorder stops at 9000, but I hit the rev limiter at the stripe which was set at 9200 . I only been 8980 something with 5/16" pushrods.......but the slicks I used then were different & taller.

Bottom line: I tested it for myself, and its no big deal for what I mess with. NO POWER there.

Your results may vary......

http://i956.photobucket.com/albums/ae45 ... 24b0be.jpg

Hey Sanford and son:

Some people just talk RPM .....I record it. 9200 rpm on this pass Oct 11 2014. The data recorder stops at 9000, but I hit the rev limiter at the stripe which was set at 9200 . I only been 8980 something with 5/16" pushrods.......but the slicks I used then were different & taller.

Bottom line: I tested it for myself, and its no big deal for what I mess with. NO POWER there.

Your results may vary......

http://i956.photobucket.com/albums/ae45 ... 24b0be.jpg

"I promise you Sheriff, I won't throw one more rock... Didn't say nothin' 'bout no brick!" --Ernest T Bass

-

sanfordandson

- Guru

- Posts: 6046

- Joined: Sat May 20, 2006 6:28 pm

- Location:

Re: Push rod

And they certainly have, as well as many others. Power is only 1 part of the equation. Enjoy your spaghetti noodle valvetrain.MrBo wrote:Your results may vary......

Re: Push rod

Put your valve train together with checking springs and check your lift.sanfordandson wrote:And they certainly have, as well as many others. Power is only 1 part of the equation. Enjoy your spaghetti noodle valvetrain.MrBo wrote:Your results may vary......

Put your real springs on and see the loss……say .030” ???

Put your big pushrods in and you will see the same .030” loss.

How much does a 8” pushrod need to bend to lose just half that--- .015” in length?

That should get you started.

"I promise you Sheriff, I won't throw one more rock... Didn't say nothin' 'bout no brick!" --Ernest T Bass

-

Warp Speed

- Guru

- Posts: 3285

- Joined: Wed Jun 25, 2008 1:46 pm

- Location: NC

Re: Push rod

If you measured any of this dynamically, you would get a completely different story!MrBo wrote:Put your valve train together with checking springs and check your lift.sanfordandson wrote:And they certainly have, as well as many others. Power is only 1 part of the equation. Enjoy your spaghetti noodle valvetrain.MrBo wrote:Your results may vary......

Put your real springs on and see the loss……say .030” ???

Put your big pushrods in and you will see the same .030” loss.

How much does a 8” pushrod need to bend to lose just half that--- .015” in length?

That should get you started.

Love racing guys like you!

- needforspeed66gt

- Guru

- Posts: 2069

- Joined: Sat May 06, 2006 6:18 pm

- Location: California

Re: Push rod

On our 7500+ rpm motors that use a tall roller lifter and end up with a 6.8" push rod, the 5/16 push rod has not been problematic. But nearly the same motor with some different heads and valve lengths, necessitating a longer push rod ended up with pounded seats on first inspection, changing to a 3/8" push rod eliminated this problem and gained a couple hundred rpm due to what is pretty obviously bounce induced by a flexing push rod.

Jumping in and calling people idiots because they have found that certain parts gain longevity and power is quite childish.

Jumping in and calling people idiots because they have found that certain parts gain longevity and power is quite childish.

Nate @steeldustmachine

Engine Machinist

Engine Machinist

-

sanfordandson

- Guru

- Posts: 6046

- Joined: Sat May 20, 2006 6:28 pm

- Location:

Re: Push rod

You should call manton, trend or smith bros and ask them for their new hipo 1/4 pushrods. If small is good smaller MUST be better! Make sure you post up one of your sweet graphs when you are done so we can all learn.MrBo wrote:Put your valve train together with checking springs and check your lift.sanfordandson wrote:And they certainly have, as well as many others. Power is only 1 part of the equation. Enjoy your spaghetti noodle valvetrain.MrBo wrote:Your results may vary......

Put your real springs on and see the loss……say .030” ???

Put your big pushrods in and you will see the same .030” loss.

How much does a 8” pushrod need to bend to lose just half that--- .015” in length?

That should get you started.

Re: Push rod

I may not be as dumb as you think. I went after the source that makes valve train parts want to bend in dynamic conditions in the first place. Weight.Warp Speed wrote: If you measured any of this dynamically, you would get a completely different story!

Love racing guys like you!

I have 2.08” intake valves that weigh 139g, 125g and 85grams. The 85g titanium valves are in this engine. They make my rocker arms bend less, the pushrods act bigger and my camshaft barrel seem thicker.

The importance of weight is exponential because of accelerations. Stiffness is stiffness. I never said it was not important.

Guys can weigh all their parts with a $30 scale now-a-days. You don’t always hear guys talking about the weight of their valves, retainers, locks or springs do you. I wonder why?

Must be way underrated.

"I promise you Sheriff, I won't throw one more rock... Didn't say nothin' 'bout no brick!" --Ernest T Bass

-

stokerboats

- Pro

- Posts: 427

- Joined: Sat Jul 14, 2012 5:08 pm

- Location:

Re: Push rod

I'm thinking a lightweight valve is greatly beneficial but that said, so is a non flexing pushrod. Together you have a happier valvetrain.MrBo wrote:I may not be as dumb as you think. I went after the source that makes valve train parts want to bend in dynamic conditions in the first place. Weight.Warp Speed wrote: If you measured any of this dynamically, you would get a completely different story!

Love racing guys like you!

I have 2.08” intake valves that weigh 139g, 125g and 85grams. The 85g titanium valves are in this engine. They make my rocker arms bend less, the pushrods act bigger and my camshaft barrel seem thicker.

The importance of weight is exponential because of accelerations. Stiffness is stiffness. I never said it was not important.

Guys can weigh all their parts with a $30 scale now-a-days. You don’t always hear guys talking about the weight of their valves, retainers, locks or springs do you. I wonder why?

Must be way underrated.

Re: Push rod

I wouldn’t worry about me calling people idiots. I am an idiot myself.needforspeed66gt wrote: Jumping in and calling people idiots because they have found that certain parts gain longevity and power is quite childish.

About 8 years ago someone I know quite well called me an idiot savant. I didn’t know what that meant.

I had to look it up.

"I promise you Sheriff, I won't throw one more rock... Didn't say nothin' 'bout no brick!" --Ernest T Bass

-

piston guy

- Guru

- Posts: 1029

- Joined: Mon Sep 10, 2012 1:55 pm

- Location: Anaheim, CA

Re: Push rod

Warp Speed,

Are you guys still @ 7/16ths on you puny 358's ? LOL I heard some were at 1/2" ( tapered) with those knife edge steel rockers. I understand if it's still "top secret".

Are you guys still @ 7/16ths on you puny 358's ? LOL I heard some were at 1/2" ( tapered) with those knife edge steel rockers. I understand if it's still "top secret".

-

Warp Speed

- Guru

- Posts: 3285

- Joined: Wed Jun 25, 2008 1:46 pm

- Location: NC

Re: Push rod

Nope, not top secret on the pushrod size, as you can buy them by the pallet from used parts. LOLpiston guy wrote:Warp Speed,

Are you guys still @ 7/16ths on you puny 358's ? LOL I heard some were at 1/2" ( tapered) with those knife edge steel rockers. I understand if it's still "top secret".

Straight 1/2 x .165 wall is the minimum we can get away with.

That is with Very light weight parts also .............!?!

-

sanfordandson

- Guru

- Posts: 6046

- Joined: Sat May 20, 2006 6:28 pm

- Location:

Re: Push rod

Warp Speed wrote:Nope, not top secret on the pushrod size, as you can buy them by the pallet from used parts. LOL

Straight 1/2 x .165 wall is the minimum we can get away with.

That is with Very light weight parts also .............!?!

Impossible!! Show me a graph!!!