Hotting up a 502 Crate

Moderator: Team

-

BigBlocksOnTop2

- Pro

- Posts: 492

- Joined: Thu Mar 21, 2013 12:03 pm

- Location: Chancellorsville Battle Field, Chancellorsville, Virginia

Re: Hotting up a 502 Crate

Watching this thread with great interest. Like Randy, I've often wondered how flowbench exhaust numbers really correlate with hot exhaust gases at a MUCH different pressure differential.

it's amazing just how much we DON'T know about this 100+ year old invention called "the internal combustion engine".

The engineers are getting smarter though. Just look at the engine in any production sedan today vs what they were running 20 years ago.

Sorry - nothing of value to add... just wanted to subscribe.

it's amazing just how much we DON'T know about this 100+ year old invention called "the internal combustion engine".

The engineers are getting smarter though. Just look at the engine in any production sedan today vs what they were running 20 years ago.

Sorry - nothing of value to add... just wanted to subscribe.

Re: Hotting up a 502 Crate

Hi ! I'm the owner of the car.

I'm looking to run low tens in street trim but there's a long way there, and my first goal is to get that 6.99 10.99 120mph pass. Hoping to get that done without adding huge mods to the engine.

Let me try and list my combo accurately.

Car is a 1965 Chevelle.

3870lb with me in it at the starting line.

Best run is my last: 1.56 7.05 11.17 @ 118.6mph

Engine:

1000hp (930cfm) prosystems carb

Zz502 stock but added 242/252 595/612 lsa110 lunati cam and shimmed springs 0.060". Haven't measured spring pressure but far from coil binding.

Custom made 11.20:1 pistons with 0.040quench.

Running 1 3/4" full length headers into very open 3" exhaust out the back.

Comment: it doesn't rpm very well, feel it's peaking at 5500, and quite quickly falls on it's face at 6000rpm. I've taken it to 6700once when I missed third, it valve floats at 6700.

I think it would benefit from a cam with a tighter lsa and lift in the 630 area ?

I have a 1" spacer and 2" exhaust that I'm going to try next time out.

Converter

5500 stall coan.

Home built Th400, shifts firm but not harsh.

3.73:1 Moser rear end

315/60-15 M/T drag radial - too big I`m mounting 295/65 next time out (not ideal but I like how they work on the street and think I can do ok with them with alot of chassi tuning ?)

Suspension

Chris alston chassiworks shocks. DA front, SA rear.

Moroso trick springs (not tested yet, old was cut L6 springs)

No front sway bar. Spc uppers and long ball joints.

Rear

Currie arms, adjustable uppers

Spc lowering springs but spaced up to fit the wide tires which basically messes up my instant center, pinion angle. So rear end is far from being ideal until these tires are worn out. Doing huge burnouts for fun I guess the tires are gone by the end of august. These tires needs pretty small burnouts I know.

BMR anti roll bar, new - last run was with helwig pro touring sway bar.

I´ve been having trouble getting it to hook right. It lifts the front, but not fast enough to really plant the tires. Will be testing more next time, and had some adjustments going out on the front shocks (four clicks from full loose). Fixing that and the moroso springs the front end seems like a totally new car and hooks alot better on the street and really raises the front alot more.

Got about 6" travel in the front. And will be double nutting the lower arms as they are a bit slow, and binding some.

I´m working on getting it to hook great, hoping to go into the 1.4x´s with the engine as is. And when it´s hooking great, I`ll be adding more power until I`m getting my low ten sec pass Any advise getting me closer is appreciated.

Any advise getting me closer is appreciated.

I'm looking to run low tens in street trim but there's a long way there, and my first goal is to get that 6.99 10.99 120mph pass. Hoping to get that done without adding huge mods to the engine.

Let me try and list my combo accurately.

Car is a 1965 Chevelle.

3870lb with me in it at the starting line.

Best run is my last: 1.56 7.05 11.17 @ 118.6mph

Engine:

1000hp (930cfm) prosystems carb

Zz502 stock but added 242/252 595/612 lsa110 lunati cam and shimmed springs 0.060". Haven't measured spring pressure but far from coil binding.

Custom made 11.20:1 pistons with 0.040quench.

Running 1 3/4" full length headers into very open 3" exhaust out the back.

Comment: it doesn't rpm very well, feel it's peaking at 5500, and quite quickly falls on it's face at 6000rpm. I've taken it to 6700once when I missed third, it valve floats at 6700.

I think it would benefit from a cam with a tighter lsa and lift in the 630 area ?

I have a 1" spacer and 2" exhaust that I'm going to try next time out.

Converter

5500 stall coan.

Home built Th400, shifts firm but not harsh.

3.73:1 Moser rear end

315/60-15 M/T drag radial - too big I`m mounting 295/65 next time out (not ideal but I like how they work on the street and think I can do ok with them with alot of chassi tuning ?)

Suspension

Chris alston chassiworks shocks. DA front, SA rear.

Moroso trick springs (not tested yet, old was cut L6 springs)

No front sway bar. Spc uppers and long ball joints.

Rear

Currie arms, adjustable uppers

Spc lowering springs but spaced up to fit the wide tires which basically messes up my instant center, pinion angle. So rear end is far from being ideal until these tires are worn out. Doing huge burnouts for fun I guess the tires are gone by the end of august. These tires needs pretty small burnouts I know.

BMR anti roll bar, new - last run was with helwig pro touring sway bar.

I´ve been having trouble getting it to hook right. It lifts the front, but not fast enough to really plant the tires. Will be testing more next time, and had some adjustments going out on the front shocks (four clicks from full loose). Fixing that and the moroso springs the front end seems like a totally new car and hooks alot better on the street and really raises the front alot more.

Got about 6" travel in the front. And will be double nutting the lower arms as they are a bit slow, and binding some.

I´m working on getting it to hook great, hoping to go into the 1.4x´s with the engine as is. And when it´s hooking great, I`ll be adding more power until I`m getting my low ten sec pass

-

user-612937456

Re: Hotting up a 502 Crate

I suggest a lower gear than the 3.73's (whats your rpm through the traps at 118?) even tho its a street car with a 5500 stall you are not concerned about economy plus you will have some more RPM's for you MPH's with a more appropriate cam grind, if you stay with the higher gear the 2" EX may loose you some torque I would consider a set of 1 7/8's primary's, I like the 108-110 LSA for your compression on pump gas but definitely more duration and lift . Have you considered EX cut outs for the timed runs? As you may have read so much about cam discussion don't put too much stock into 14 different guesses as to what you need, grant it some may be close but you will get a more optimal cam if you talk to a competent cam grinder and have them grind one specifically for your combo.

-

user-612937456

Re: Hotting up a 502 Crate

BTW Randy I let you win I am tired debating if you think the world is flat and we will fall off if we get too close to the edge you must be right. After all if airflow patterns are known at a specific control pressure then flow characteristics can not be predicted at different pressures and temperatures with a good algorithm.

So let me see if I understand your thinking since you cant understand the cfm flow of a port configuration, are you saying that a 383 with 882 style ports can use the same .630 lift cam just just as efficiently as a port config in a set of AFR 245's? Can a head that intake flow flattens out above .500 lift have a negative affect to the tumble or turbulence? Does the lesser flowing head need same off seat time as the higher flowing head? Does a different IN/EX % balance of flow require a the same valve overlap timing?

So let me see if I understand your thinking since you cant understand the cfm flow of a port configuration, are you saying that a 383 with 882 style ports can use the same .630 lift cam just just as efficiently as a port config in a set of AFR 245's? Can a head that intake flow flattens out above .500 lift have a negative affect to the tumble or turbulence? Does the lesser flowing head need same off seat time as the higher flowing head? Does a different IN/EX % balance of flow require a the same valve overlap timing?

-

swatson454

- Guru

- Posts: 1500

- Joined: Thu Sep 03, 2009 6:06 pm

- Location: Dripping Springs, Texas

Re: Hotting up a 502 Crate

Might be time to go solid roller. I'm thinking:

255/262

.680/.645

108 LSA

I like GVX's exhaust idea. Have you thought about a Sniper intake?

Shawn

255/262

.680/.645

108 LSA

I like GVX's exhaust idea. Have you thought about a Sniper intake?

Shawn

Live in such a way that those who know you but don't know God will come to know God because they know you.

Re: Hotting up a 502 Crate

Win? We haven't even raced yet!!gvx wrote: BTW Randy I let you win I am tired debating if you think the world is flat and we will fall off if we get too close to the edge you must be right. After all if airflow patterns are known at a specific control pressure then flow characteristics can not be predicted at different pressures and temperatures with a good algorithm.

I have a flow bench and use it regularly. But, I view cfm differently than I did 30 years ago when I built my first bench. The bench can give you usable data, but telling you how to cam an engine isn't one of them.

And no, having flow data at 28" won't guarantee what it will flow at 200 psi. Sure the theoretical increase can be calculated, but I've seen more than one port not follow that math simply raising the depression from 28" to 40". So,.. what's the odds ports generally do at 5 psi,..10 psi,.. or 200 psi???

I don't recall saying different heads wouldn't change cam requirements. And, no a lesser flowing head wouldn't automatically need more overlap because of flow bench cfm.gvx wrote: So let me see if I understand your thinking since you cant understand the cfm flow of a port configuration, are you saying that a 383 with 882 style ports can use the same .630 lift cam just just as efficiently as a port config in a set of AFR 245's? Can a head that intake flow flattens out above .500 lift have a negative affect to the tumble or turbulence? Does the lesser flowing head need same off seat time as the higher flowing head? Does a different IN/EX % balance of flow require a the same valve overlap timing?

I need to head to work now, BUT I'm afraid my closed, getto, simple mind won't be able to keep my old work truck from driving right off the edge of the earth!!!

PS, gvx I knew you wouldn't entertain a different point of view from the start, but there others that read this and might, as in novadude and bigblocksontop2 for example seem to at least be entertaining the idea that flow bench cfm doesn't tell us much about an ex port.

Randy

-

swatson454

- Guru

- Posts: 1500

- Joined: Thu Sep 03, 2009 6:06 pm

- Location: Dripping Springs, Texas

Re: Hotting up a 502 Crate

I'm on that list as well, assuming the port isn't jacked up. I do believe, however, that Cd at low lift can be helpful in determining EVC and, thus, influence LSA.randy331 wrote:...but there others that read this and might, as in novadude and bigblocksontop2 for example seem to at least be entertaining the idea that flow bench cfm doesn't tell us much about an ex port.

Randy

Shawn

I should've worded that better. Actual low-lift flow at a reduced pressure is probably a better way to say it... maybe. First cup of coffee

Last edited by swatson454 on Fri Aug 01, 2014 10:06 am, edited 1 time in total.

Live in such a way that those who know you but don't know God will come to know God because they know you.

-

user-612937456

Re: Hotting up a 502 Crate

40" of depression? I think physics prevent us from going beyond 30" but lets not debate that.

I just don't think you grasp my point. I am not saying that flow data is critical it should be considered as an over weighted piece of information in choosing your cam but it is data that should and does influence your choice whether you want to admit it or not.

"I don't recall saying different heads wouldn't change cam requirements." What form of ruler do you use to gauge or measure which head is lesser or greater? For each application they look about the same to me in physical appearance. Why do different heads change cam requirements? Would you consider the same head that has been ported to flow a 50 CFM improvement lesser or greater before and after? If I have missed the point again what do you mean by different heads if you are not referring to the volume of air they will flow?

I never said that flow bench data told you everything about the dynamics of a port all I am saying is that it is information it is a fixed reference point.

You do use a form of measurement that influences your choice for a different cam. I don't care if you use math or cave man drawings to measure one port from another but the fact you are using some form of measurement to make slight modifications in the cam choice based on which head and what it is capable of.

Maybe you knew that lady down in Louisiana that teaches that magical Voodoo formula LOL What was her name Marie Levoe?

I just don't think you grasp my point. I am not saying that flow data is critical it should be considered as an over weighted piece of information in choosing your cam but it is data that should and does influence your choice whether you want to admit it or not.

"I don't recall saying different heads wouldn't change cam requirements." What form of ruler do you use to gauge or measure which head is lesser or greater? For each application they look about the same to me in physical appearance. Why do different heads change cam requirements? Would you consider the same head that has been ported to flow a 50 CFM improvement lesser or greater before and after? If I have missed the point again what do you mean by different heads if you are not referring to the volume of air they will flow?

I never said that flow bench data told you everything about the dynamics of a port all I am saying is that it is information it is a fixed reference point.

You do use a form of measurement that influences your choice for a different cam. I don't care if you use math or cave man drawings to measure one port from another but the fact you are using some form of measurement to make slight modifications in the cam choice based on which head and what it is capable of.

Maybe you knew that lady down in Louisiana that teaches that magical Voodoo formula LOL What was her name Marie Levoe?

Last edited by user-612937456 on Fri Aug 01, 2014 10:50 am, edited 2 times in total.

Re: Hotting up a 502 Crate

Back on subject, Rokker, you need more duration to turn more rpm with that many cubes. 242 degrees will be ok at 6000 for a 400 inch motor, you need more cam for your 25 percent larger motor.

So much to do, so little time...

Re: Hotting up a 502 Crate

Was the question ever answered about which heads?

are they pocket ported?

rockers?

check the springs

what pressures

are they pocket ported?

rockers?

check the springs

what pressures

Re: Hotting up a 502 Crate

Could easily go either way.gvx wrote: Would you consider the same head that has been ported to flow a 50 CFM improvement lesser or greater before and after?

-

user-612937456

Re: Hotting up a 502 Crate

Agreed yes the change could go either way depending on the application. But put this into context of the expressed opinion of whether the change may affect the choice of cam grind on an engine that will be improved by a better flowing head because there would be no relevance in the question in where the different head would not benefit the engine packageCGT wrote:Could easily go either way.gvx wrote: Would you consider the same head that has been ported to flow a 50 CFM improvement lesser or greater before and after?

Re: Hotting up a 502 Crate

Get rid of those 1 3/4" headers, go to a 2" with a 3" collector. I just ran this exact test on my own 600+ HP 496 and the 1 3/4" headers cost power almost all the way up.Rokker wrote:Hi ! I'm the owner of the car.

I'm looking to run low tens in street trim but there's a long way there, and my first goal is to get that 6.99 10.99 120mph pass. Hoping to get that done without adding huge mods to the engine.

Let me try and list my combo accurately.

.......Running 1 3/4" full length headers into very open 3" exhaust out the back.

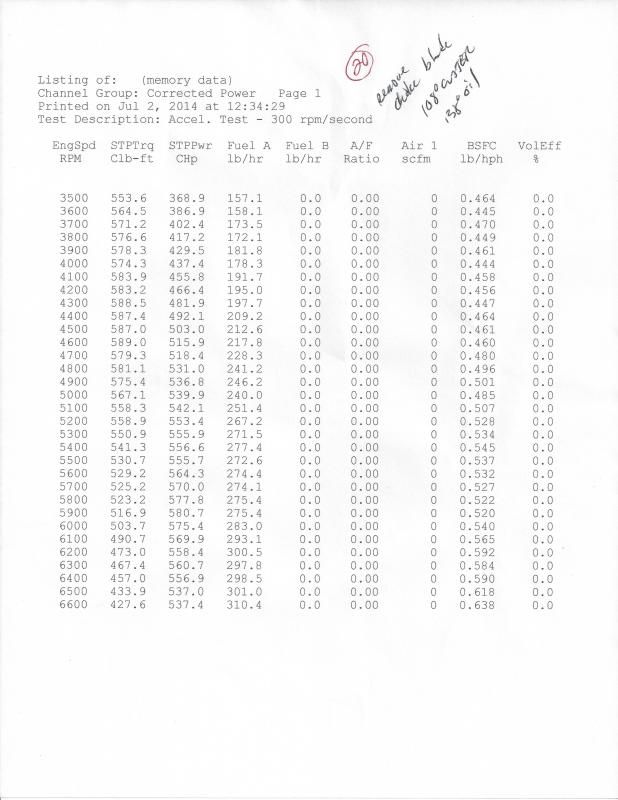

Pull with 2" X 3" headers, 18" collector extensions:

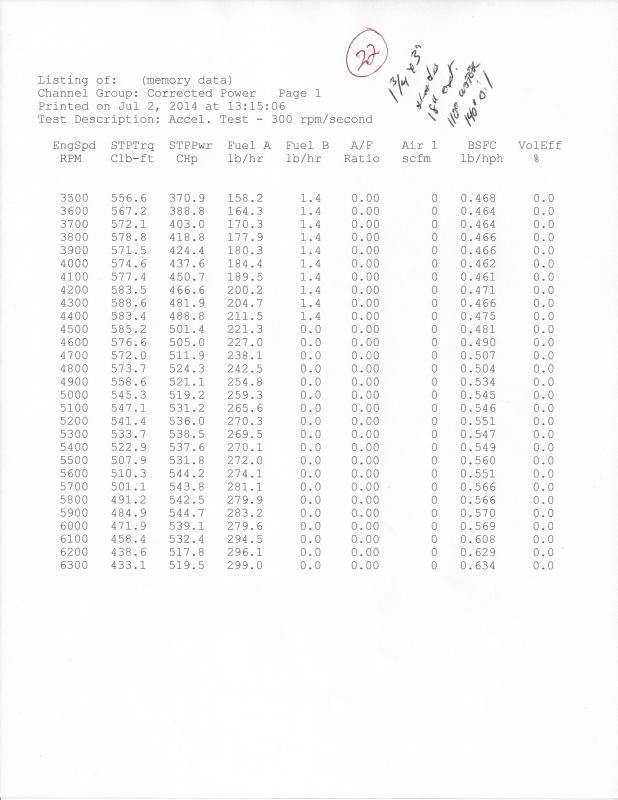

No other changes but 1 3/4" X 3" headers with 18" collector extensions:

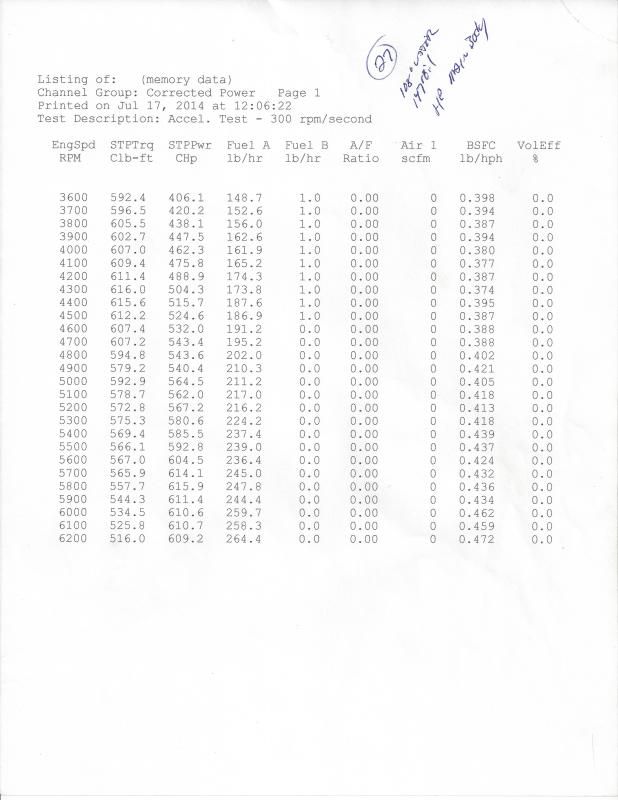

FWIW, a few pulls later after a few carb mods and an oil pan swap:

Re: Hotting up a 502 Crate

Where did you get this information? Maybe your confusing " of water and " of mercury?gvx wrote:40" of depression? I think physics prevent us from going beyond 30" but lets not debate that.

I don't know anyone using 28" of mercury on a flow bench. That would be what about 380" of water?

Id say It'd be a fair assumption to say that goes both ways!!!gvx wrote: I just don't think you grasp my point.

I think marie has a new formula. I'd head down there now, but I'm afraid I'd take a wrong turn out of the getto and drive off the edge of the earth.gvx wrote: Maybe you knew that lady down in Louisiana that teaches that magical Voodoo formula LOL What was her name Marie Levoe?

Randy