Cam bearing failure x2.. help...

Moderator: Team

-

jesengines

- Member

- Posts: 98

- Joined: Sun Aug 05, 2007 11:55 pm

- Location: Minnesota

Re: Cam bearing failure x2.. help...

Hard to believe that know one has mentioned valve spring coil bind. You mentioned Harland sharp rockers and I immediately thought coil bind. Make sure your valvetrain geometry is correct. Mock up your hyd lifter to be solid against the snap ring, verify your lift is what you expect it to be as per cam card and works with the valve spring while mocked up on the engine. Harland sharp rockers are known to be heavy on ratio (1.5 ratios really measure 1.57 etc.) If your pushrod length is off .050 or .100" you can gain lift through overarcing the rocker. IMO, You are not having an oiling issue but coil bind, rocker stud flex, trying to wedge the pushrods against the pumped up lifters, into the cam and the cam bearings are taking the brunt of the issue. See it all the time in performance engines that are rushed together by the shops trying to make a quick buck, when I see cam bearings like those thats the first thing I check during teardown.

Performance engines are a science, no question is answered until proven.

Re: Cam bearing failure x2.. help...

Hmmmmm......jesengines wrote:....... See it all the time in performance engines that are rushed together by the shops trying to make a quick buck, when I see cam bearings like those thats the first thing I check during teardown.

Re: Cam bearing failure x2.. help...

I checked for coil bind and any other bind. I checked retainer to valve seal clearance and rocker binding. Checked on assembly and disassembly.

Re: Cam bearing failure x2.. help...

We are putting it back together.

I noticed that the oil drain back holes to the rear still had a bit of casting flash on them so I cleaned that up.

Block cleaned x3, cam bearings installed, crank installed with .0018-.0020" clearance.

Melling HV pump

King bearings Main and rod

Durabond cam bearings

Clay Smith cam

Johnson/Hylift lifters

.040" restrictor pushrods.

I was going to go with a set of stock lifters. However I ordered one of the Mopar Performance and OEM. I was quite disappointed when I found they were different from the stock one I had and were like every other aftermarket lifter.

Besides checking the valve train again with solid lifters, checking the rod and main clearances, checking the lifter to bore clearances and checking the cam to cam bearing clearances, anything else I need to pay attention to?

I noticed that the oil drain back holes to the rear still had a bit of casting flash on them so I cleaned that up.

Block cleaned x3, cam bearings installed, crank installed with .0018-.0020" clearance.

Melling HV pump

King bearings Main and rod

Durabond cam bearings

Clay Smith cam

Johnson/Hylift lifters

.040" restrictor pushrods.

I was going to go with a set of stock lifters. However I ordered one of the Mopar Performance and OEM. I was quite disappointed when I found they were different from the stock one I had and were like every other aftermarket lifter.

Besides checking the valve train again with solid lifters, checking the rod and main clearances, checking the lifter to bore clearances and checking the cam to cam bearing clearances, anything else I need to pay attention to?

-

CHT

Re: Cam bearing failure x2.. help...

Not being aware of the oilways in your particular motor, do the cam bearings take their oil from the mains, meaning the gally goes from the lifters to the mains then back to the cam bearing?

I may have missed it if you listed the main bearing oil clearance so what is the clearance there.

I may have missed it if you listed the main bearing oil clearance so what is the clearance there.

Re: Cam bearing failure x2.. help...

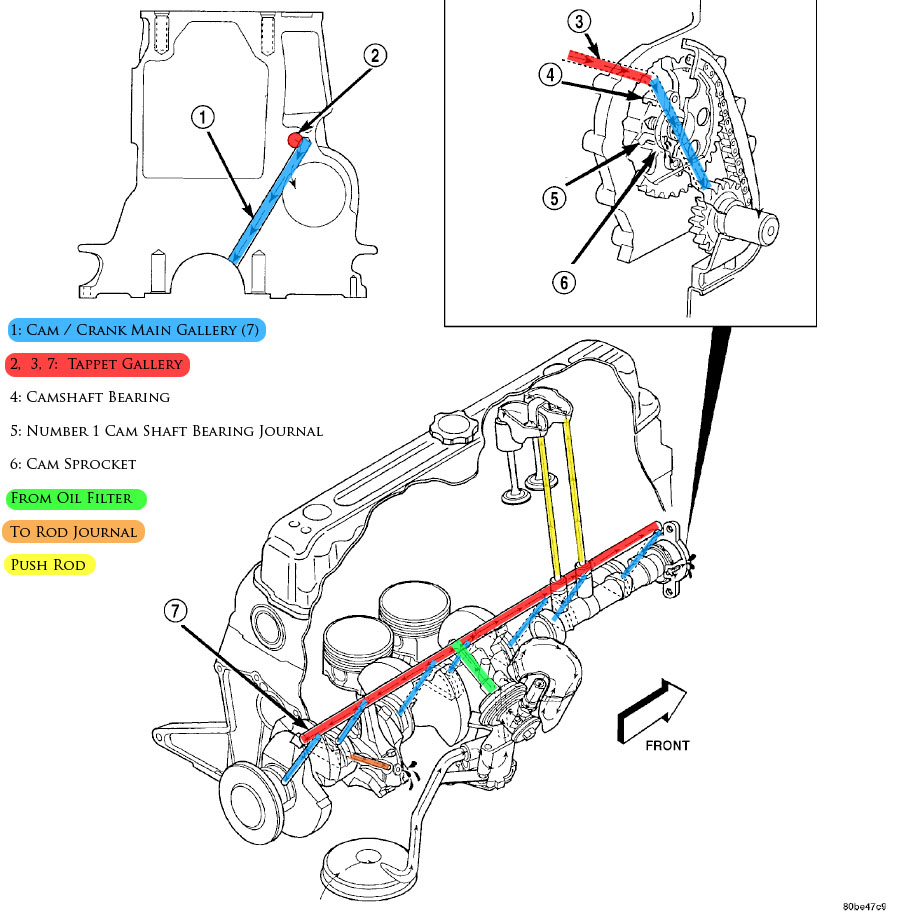

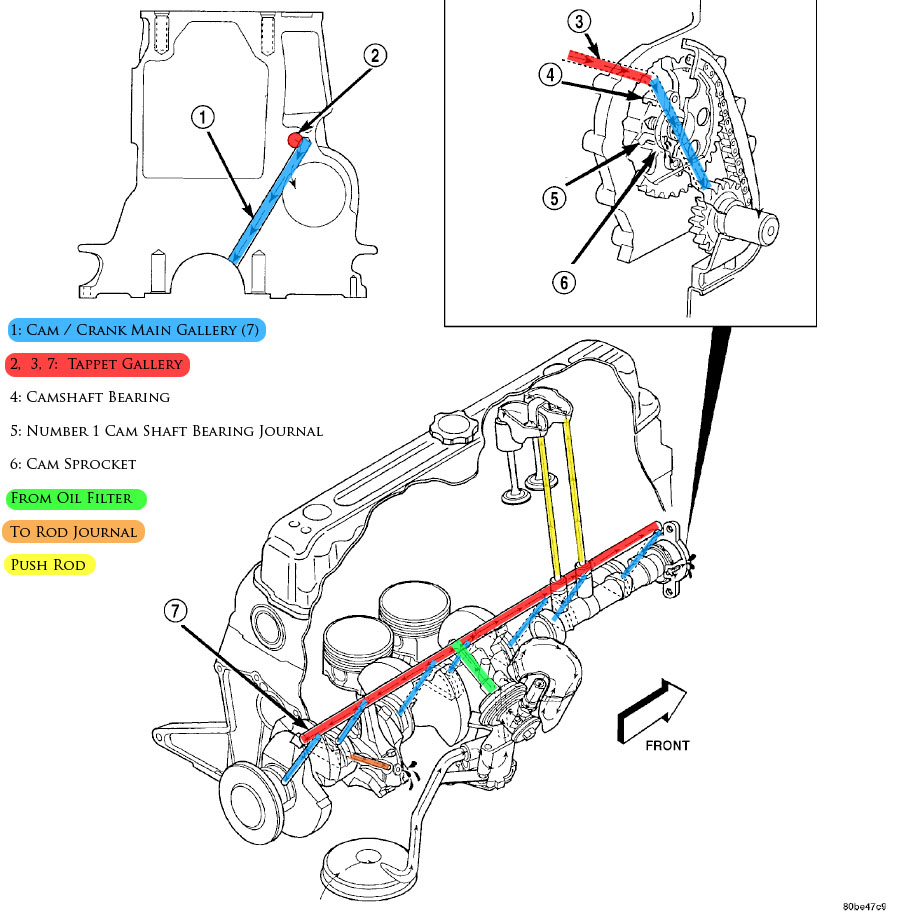

Th oil goes from the main galley to the cam bearings, when to the mains. Main clearance is .0018-.0020"

-

Dodge Freak

- Guru

- Posts: 1711

- Joined: Sun Oct 21, 2007 6:56 pm

- Location:

Re: Cam bearing failure x2.. help...

I might be crazy but after 2 cam bearing failures I would just replace all the valve springs and triple check while its apart the valve guild to retainer clearance....on all 16 valves. Once in while they are not all the same.

Re: Cam bearing failure x2.. help...

Retainer to seat/guide clearance has been checked as have all the springs. Spring load has been checked as well. 100 seat, 240 open, give or take a few pounds between springs. Install height is 1.69", open is 1.22", bind is 1.043"

Re: Cam bearing failure x2.. help...

The short block is together. Nothing wrong found, all clearances check out. We also put some solid lifters in and threw the head and rockers on to check for binding. None. Plenty of room between the spring coils and about 1/8" between the spring retain and valve seals.

I'm going to check the push rod length this weekend and order some restrictor pushrods. I was planning on .040" restrictor hole, but they are offered in a .030" and .020" as well. The .020" being a bit more expensive. Being that I have roller rockers and they don't need a lot of oil maybe i should go with the .020" restrictors?

I'm going to check the push rod length this weekend and order some restrictor pushrods. I was planning on .040" restrictor hole, but they are offered in a .030" and .020" as well. The .020" being a bit more expensive. Being that I have roller rockers and they don't need a lot of oil maybe i should go with the .020" restrictors?

-

CHT

Re: Cam bearing failure x2.. help...

Accoding to you pics the cam is turning opposite (obviously) to the oil flowing down to the mains, did you think of grinding a lead in towards the cam bearing to ensure oil gets in there?? May be a trivial thing but worth a look if its not too late. Or increase the orifice size.

What oil are you running by the way?

What oil are you running by the way?

Re: Cam bearing failure x2.. help...

The cam bearing actually intersects the galley on the way to the main bearings. It doesn't go all the way into the galley, but about half way so the oil doesn't go through the cam bearing then to the mains. More like the oil makes a side trip off the main galley for the cam bearings. From the front of the engine the oil hole in the cam bearing is roughly at the 7 or 8 o'clock position and the cam spins clock wise. The cam bearing orifice is about 1/8"

I've ran brad penn 30 wt and joe gibbs BR for the breakins. I've used Permatex red and Royal purple assembly lube (using that now). The bearings failed in the 30 minutes of the cam break in.

I've ran brad penn 30 wt and joe gibbs BR for the breakins. I've used Permatex red and Royal purple assembly lube (using that now). The bearings failed in the 30 minutes of the cam break in.

-

CHT

Re: Cam bearing failure x2.. help...

Yes I could determine alll that thank you, Just a thought if you had've groung some bias into the bearing it may help. There are numerous mototrs that have this style of oiling to the cam bearing, some fail, some dont. Have you thought ( I may have missed it) to get the cam housing bores checked for alignment? Or had it line honed?

Re: Cam bearing failure x2.. help...

The cam bore was checked for alignment by my machinist and another one.. nothing found wrong.

-

Dodge Freak

- Guru

- Posts: 1711

- Joined: Sun Oct 21, 2007 6:56 pm

- Location:

Re: Cam bearing failure x2.. help...

So what do you think happen

Seems like something must have been wrong. I be worry if I didn't see anything wrong.

Seems like something must have been wrong. I be worry if I didn't see anything wrong.

Re: Cam bearing failure x2.. help...

The reason I gave more detail about the cam bearing oiling is that picture isn't accurate. It shows oil coming in from the 10 o'clock position when it come in lower, around the 7 o'clock position.CHT wrote:Yes I could determine alll that thank you, Just a thought if you had've groung some bias into the bearing it may help.

We didn't modify the bearings. However, bearing #2 and #4 already have a 360 ID groove in them. I don't know why the factory chose that though. What do you mean by grinding bias into the bearings exactly?

I can accept the fact that the lifters, in combination with the large hole in the rockers, are pushing too much oil to the top end and not letting enough oil go to the bottom end. But I am not the only person that runs this combo, but yet the only person that has this problem on a new engine with out any obvious faults. I have heard of 3 other people with similar bearing issues, but 1 was because of a clogged oil pump pickup, the second was because of a damaged distributor gear and the third happened recently and no info about that yet. The only common theme is lack of oil. But the others (except the third) had explainable causes to the low oil volume.